Wire Stretching

Manual wire stretching

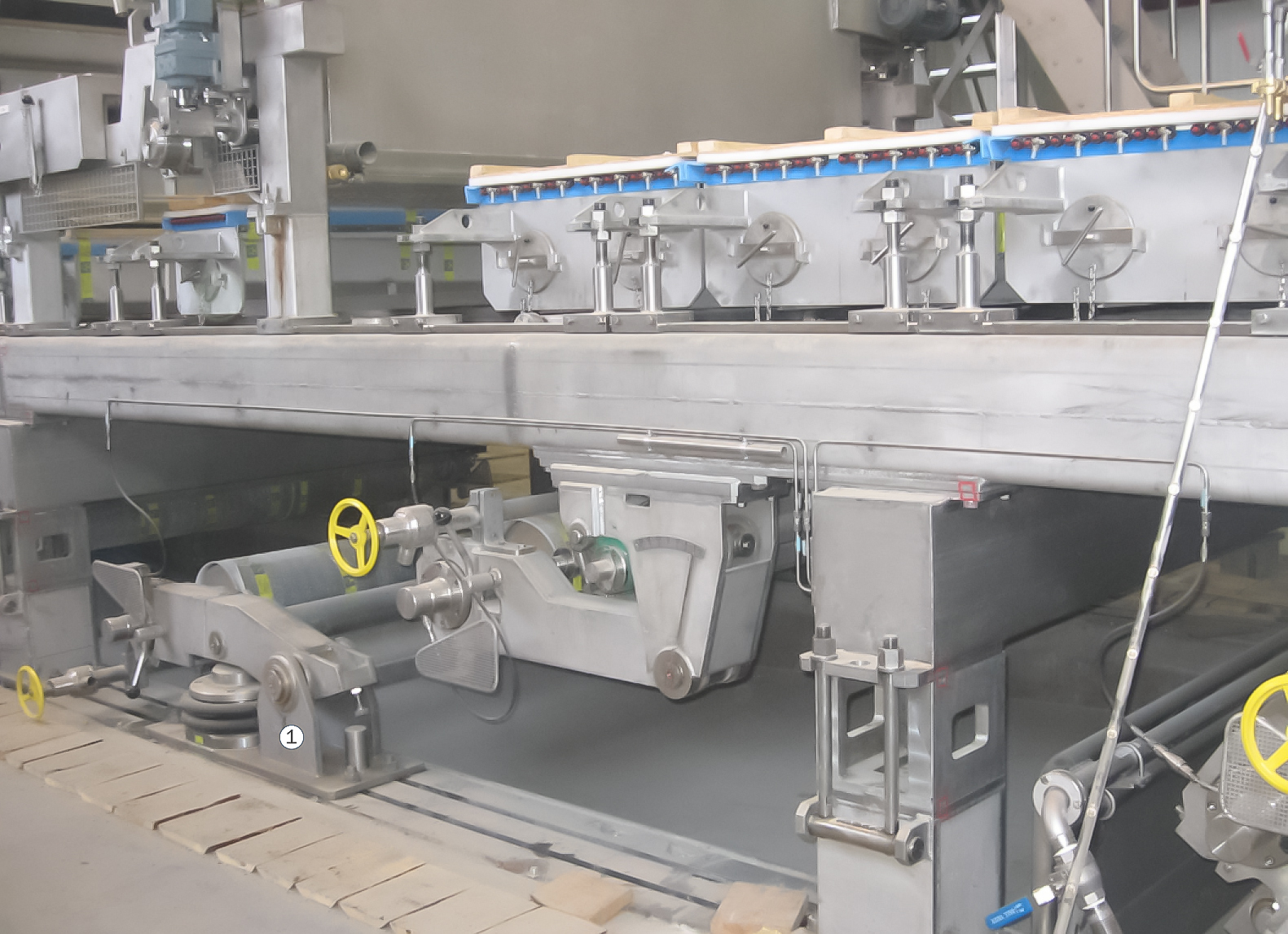

An optimal wire tension is one of basic prerequisites for an efficient PM wire part operation. An insufficiently stretched wire may bring a driving roll slippage followed by an abnormal wearing both of the wire and of the driving roll and possibly of the suction couch roll. For an optimal wire performance, that is extended during its ope-ration, it is necessary to compensate the extension. For such purposes, we deliver the wire stretching equipment in two modifications.

Design

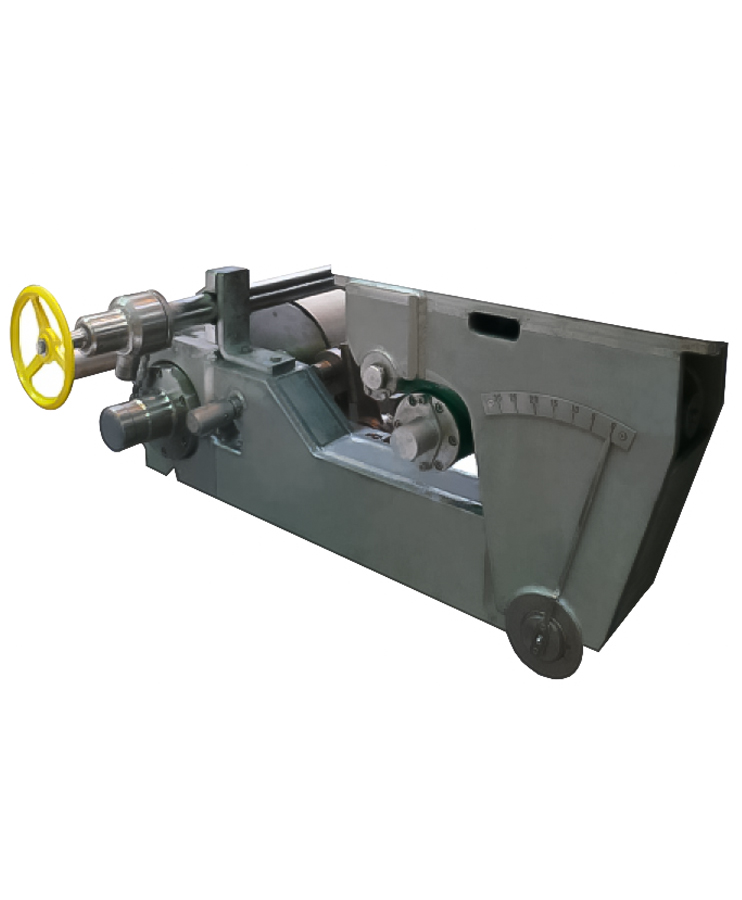

Wire stretching devices are produced and offered in top and bottom modifications. The equipment itself consists of four consoles mounted on beams or basement rails. Two consoles are provided with hinged levers for fixing of a guide roll, doctor and shower pipe. On two other consoles, there are worm gearboxes hinged and coupled with the levers by motion screws. The gearboxes are linked to each other through a driving shaft. On the gearbox drive side, there is a pneumatic motor installed.

Control machines

The basic stretching is without scanning the tension in the wire (felt). The device can be equipped with a scanner and automatic tension control. This is done subsequently through tensometric scanning sleeves installation under one of the guide rolls of the stretched wire (felt) and a relevant control system.

Stretching control

- Manual – by pneumatic distributor

- Automatic – control board / control system

Main parts

- Consoles (1)

- Worm gearboxes with pneumatic motor (2)

- Levers (3)

- Connecting shaft

Accessories

- Pneumatic distributor / electric push buttons

Material

-

Wire stretching equipment is made of stainless steel in three standard sizes:

- For bearing pitch up to 3,100 mm

- For bearing pitch up to 5,250 mm

- For bearing pitch up to 7,500 mm

Scope of delivery

- Complete machine according to main parts description

- Accessories optionally

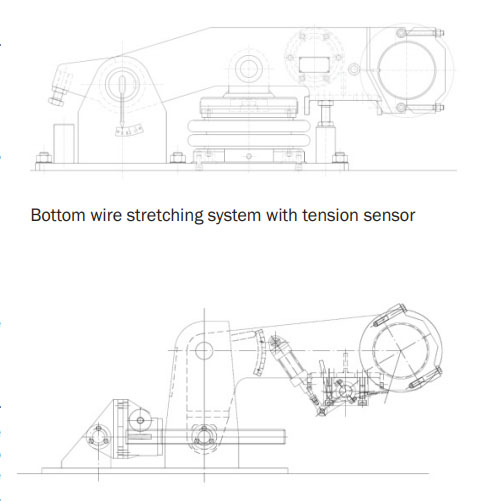

Bottom wire stretching system with a wire tension sensor is of a high importance especially during the first days of a new wire operation when the stretching and gradual settling takes place. A sensor controls the optimal tension recommended by a wire supplier during this period.

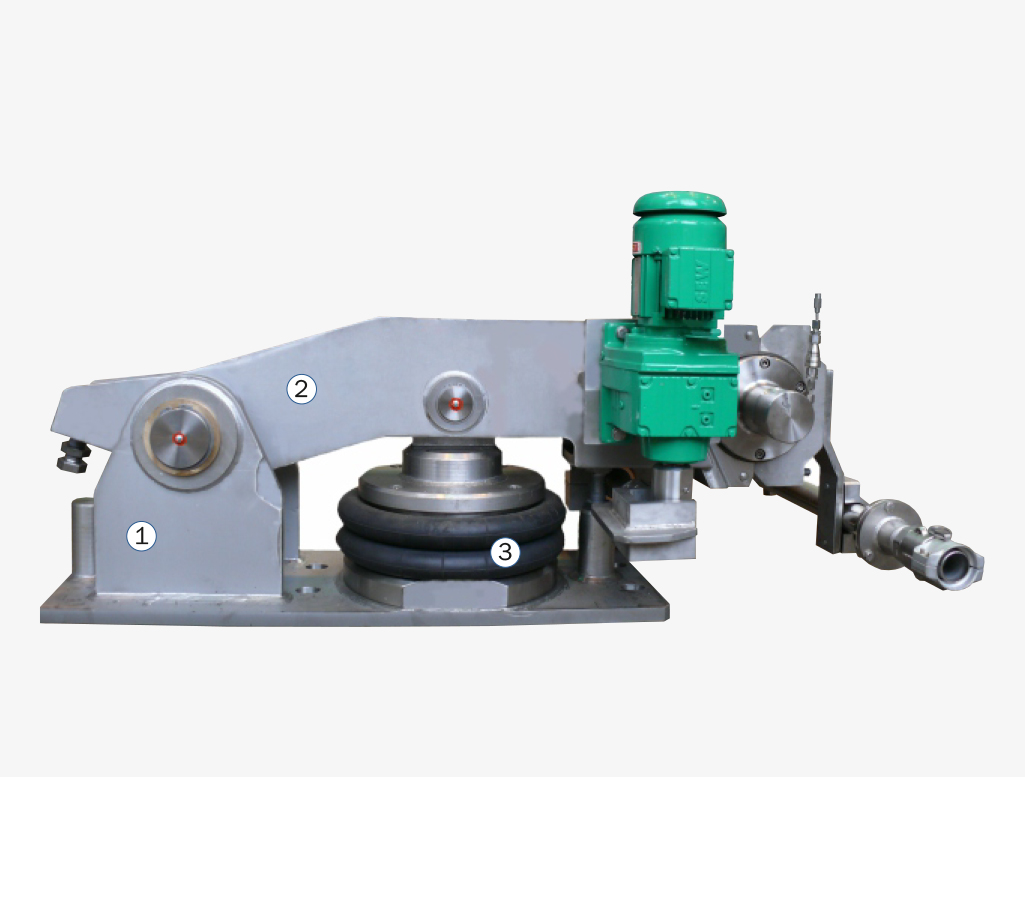

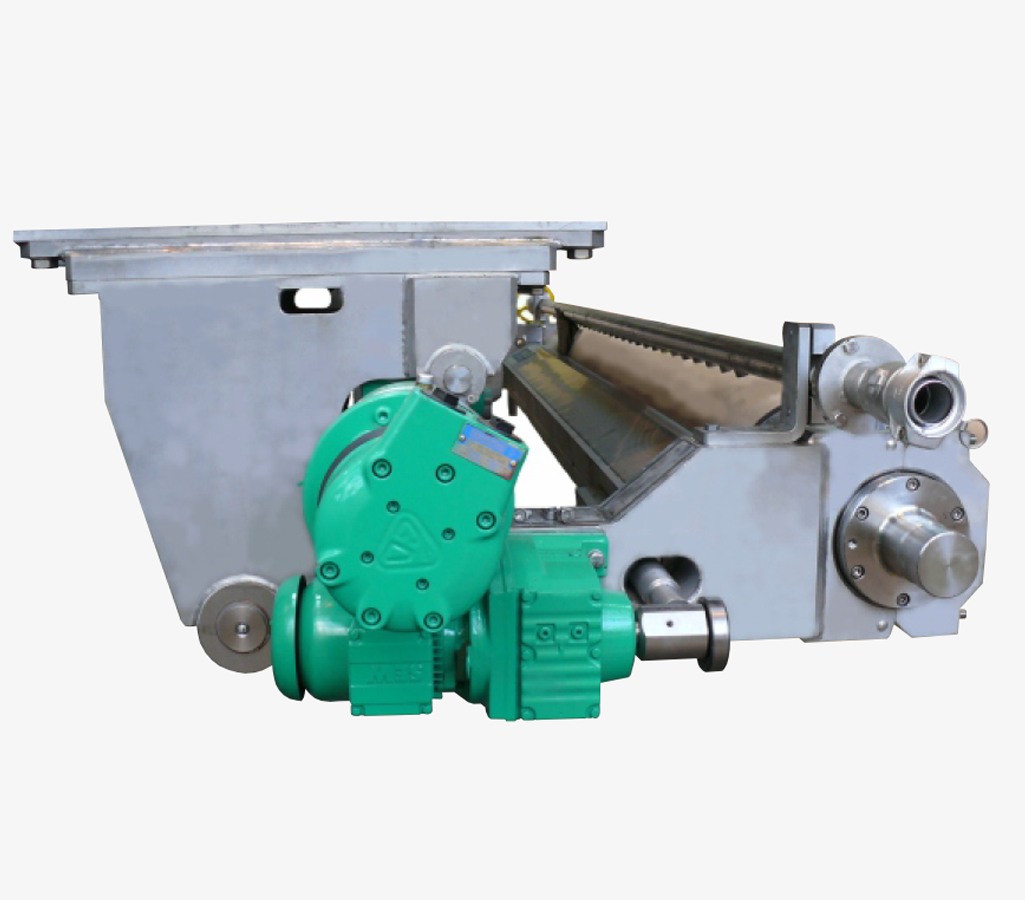

Design

Wire stretching consists of two welded consoles mounted on basement rails. Both consoles are provided with hinged levers for fixing of a guide roll, doctor and shower pipe. Pins connecting consoles with the levers are linked to each other by a connecting pipe intended for a motion coordination of both levers. The motion of levers is induced by pneumatic bellows of different sizes.

Main parts

- Consoles (1 levers (2)

- Connecting pipe

- Pneumatic bellows (3)

Material

Wire stretching is made of stainless steel in two standard sizes:

- For bearing pitch up to 3,100 mm with one pneumatic bellow

- For bearing pitch up to 5,250 mm with two pneumatic bellows

Accessories

- Control box / automatic unit

- Air distribution with proportional valve for connection to au-tomatic unit

- Tension sensor

Scope of delivery

- Complete machine according to main parts description

- Accessories optionally

Possibilities of stretching control

- Pneumatic bellows by a regulating valve and chart located on the control box and according to values shown by a pointer on a scale for lever positions

- By a lever position sensor, tension sensor and programmable automatic unit. The automatic unit controls the air supply into pneumatic bellows by a proportional valve in accordance with the given parameters and a level position linked to the tension sensing

- Standard way – fixed part regulation

-

Category

Paper Machine Section

IndustrialPaper/CulturalPaper/SpecialtyPaper

Company Presentation

[elementor-template id="3268"]