Wire Part

The wire part of the PM serves for stock dewatering and consequently it transforms the stock into the “paper sheet”. The stock goes out of the headbox on a longitudinal endless wire where the paper stock is dewatered so that the fibres settles down on the wire surface.

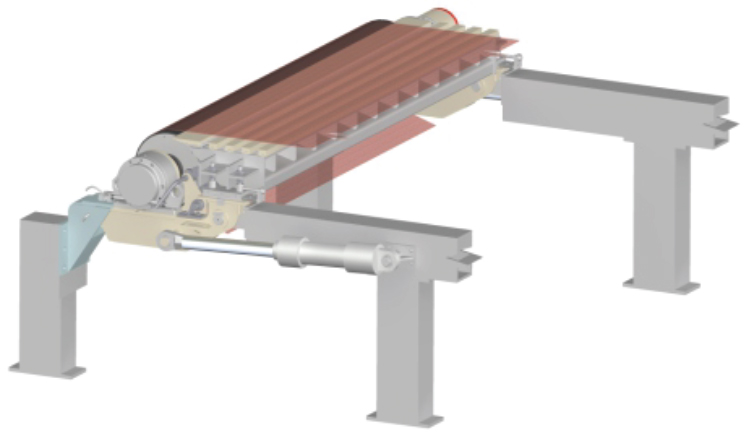

The endless wire is embraced at the headbox side by a breast roll and on the other side by a suction roll (couch roll) and driving roll. The suction and driving roll combination is recommended for each wire part version both from the drive perspective (better driving force distribution and more cautious influence on the wire itself) and from the perspective of the subsequent paper web removal and its transfer into the press part.

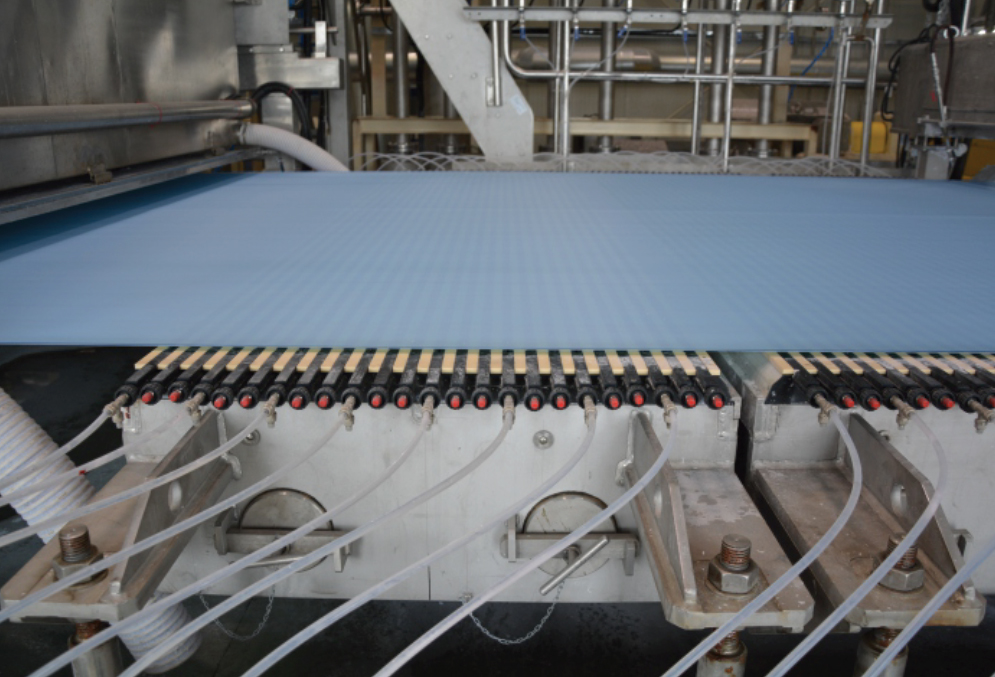

In the upper part between the rolls, dewatering elements are located, which have plastic or ceramic foils attached to them. The longitudinal endless wire with the stock is moving on their surface and in case of the contact the stock is dewatered using vacuum.

PAPCEL delivers wire tables in this design:

- Longitudinal(multi-wire)

- With top dewatering former

for paper machines with working width up to 7,500 mm and speed up toi 1,200 m/min.

Dewatering elements are located on the wire table in a following order:

- Forming board,

- Dewatering foils,

- Hydrofoils boxes,

- Vacuum water boxes,,

- Suction boxes.

The correct placement of the dewatering elements is essential for a quality dewatering to reach required percentage of the dryness after the wire part and required fibers formation. A steam box is used to increase a temperature of the paper before it enter the press part to get more of the dryness during pressing.

The wire part length depends on the PM performance and on types of paper produced there. The wire length is also determined by the number of dewatering elements.

The PM endless wire is carried, guided and stretched by a row of rolls in the lower part of the wire table. The wire guide is located there and it guides the wire so that the wire would not leave the machine axis. Manual and automatic wire stretchers are used as well and they stretch the wire for a required value (2.5 – 8.0 N/mm). In case of a reverse run, the wire is cleaned by water showers. These remove mainly the fiber that got stuck during the stock dewatering and were not separated together with the paper web running into the press part.

The paper width is secured by format showers which separate the paper web edges. These edges appearing during dewatering are rough and their passage through the PM might prevent a non-problematic production due to the appearance of breaks.

We offer a cantilever construction version of the wire part which facilitates an easy and quick wire replacing. The structure is anti- corrosive and with an adequate height to allow an easy and accessible maintenance. All other complementing features such as wire run pneumatic guide, low-pressure and high-pressure shower systems, doctors, edge threading and breakage nozzles, are seen as standard for all wire parts supplied.

Dewatering elements

The wire part purpose is to dewater the stock distributed from the headbox on the wire and ensure the creation of the “paper sheet”. That is why dewatering elements are installed on the upper wire part.

The order of dewatering elements is in paper run direction on the lower part of the wire as follows: forming board, dewatering foils, hydrofoils boxes, depression foil boxes and suction boxes. All these elements are made of stainless steel and fitted with foils, covered with polyethylene or ceramics.

For some paper grades dandy rolls and formers are used on the upper part of the wire in paper run direction.

Forming board is a weldment made of stainless steel. It is fixed to carriers on stands which enable its height adjustment against the breastrollinarangeof0-80mm.

It is fitted with a wide foil with foils of 65 mm width. These foils can be made of polyethylene or ceramics. With respect to a possible wearing the forming board is height-adjustable. All the foils are fixed on the table by T-shaped o groovings. Wiping angle of the foils is 0.

Advantages

- Height and longitudinal adjustability

- Simple foils replacement

Dewatering foil is as a weldment made of stainless steel. It is fixed to the beams with stands which enable its height adjustment. The foil design can be stationary or turnable for possible changes of its scraping angle (0 – 2.5°).

In case of the turnable design when changing the angle, is always necessary to adapt also the height adjustment accordingly.

The dewatering foil body is provided with a foil wide of 65 mm. This foil can be made of polyethylene or ceramics and fixed by a T- shaped groovings.

Hydrofoils box is a weldment made of stainless steel. It is fixed to the beams with using stands which enable its height adjustment with respect to a possible the foils wearing off. It is fitted with 5 – 7 foils with width of 65 mm. The foils can be made of polyethylene or ceramics. All the foils are fixed to the box by T-shaped groovings. Wiping angle is according the production program and according location of the box in the wire table.

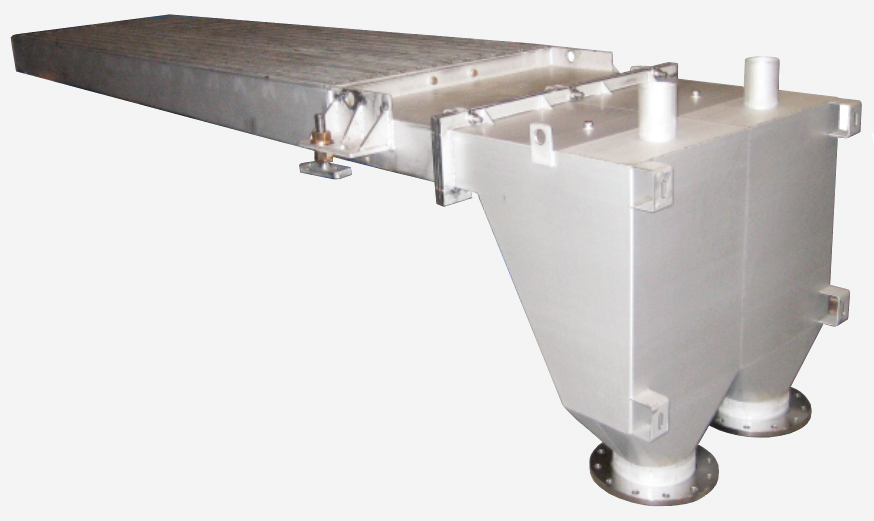

Depression water box is a weldment made of stainless steel. It is fixed to the beams with stands which enable its height adjustment with respect to possible wearing of the foils.

Itisfittedwith5-7foilswithawidthof65mm. These foils can be made of polyethylene or ceramics. All the foils are fixed to the box by T- shaped groovings.

The depression in the box is created by a fan. The depression value can be regulated by a suction valve. The suction zone width profile can be regulated by sliding gates.

Suction box is a weldment made of stainless steel. It is fixed to the beams with stands which enable a height adjustment of the box with respect to a possible wearing of the lining. The cover can be made of polyethylene or ceramics and its height ranges from 30 to 40 mm. The suction zone comprises slots or round holes. The free cover area ranges from 40 to 50% of the total lining surface. The suction zone width in the cover is adjustable by sliding gates. The box vacuum is created by a vacuum pump.

Connection to PM vacuum system is through a water separator. The vacuum regulation runs automatically using a control valve or can be done manually.

Multi-chamber suction box is a weldment made of stainless steel. It is fixed the beams on stands which enable a height adjustment of the box with respect to a possible wearing of the foils.

The foils are fixed to the box by T-shaped groovings. Each chamber is provided with a different number of foils installed with a different spacing. The vacuum value in each chamber differs from each other in order to reach optimal stock dewatering ratex in the PM wire part. Each chamber is separately connected with the PM vacuum system through a water separator. The box underpressure is created by a vacuum pump. The vacuum regulation runs auto- matically by means of a control valve or manually. The suction zone width is adjustable by means of sliding gates.

Advantages

- Height and longitudinal adjustability

- Easy foils replacement

Accessories

- M + C elements

- A + R elements

- Separators – mechanical or automatical

Each chamber is separately connected with the PM vacuum system through a water separator. The box vacuum is created by a vacuum pump. The vacuum regulation runs automatically by means of a control valve or manually. The suction zone width is adjustable by means of sliding gates.

-

Category

Paper Machine Section

IndustrialPaper/CulturalPaper/SpecialtyPaper

Company Presentation

[elementor-template id="3268"]