Waste Roll Cutter WRS

Waste roll cutters WRS are designed for cutting waste paper rolls. In the standard version, the cutter is delivered with a prismatic bed. In the extended version, it is delivered with features fastening the rolls manipulation process.

These features include:

- Auxiliary fixed or adjustable tables with cuts out for carrier manipulation

- Tilting table in combination with auxiliary tables

- Chain conveyor with steel lamellas

- Chain conveyor with steel lamellas and a folding table

- Two-belt conveyor sets

The high-performance WRS roll cutter can split rolls up to 3,000 mm width and 2,000 mm diameter

Design

The roll cutter WRS consists of a solid steel frame, on which other parts are attached. The guide rails regulate the cutting process and absorb traversal forces. The force for the proper cutting process is generated by hydraulic cylinders that are connected with a knife body. The knife body misalignment during cutting is continually adjusted by an exact divider and controlled by a position sensor. The cutting force of the machine is in the range between 600 to 800 kN depending on the cutter type (force against two cylinders).

In case of cutter and chain conveyor combination, the cutter is provided with hydraulic uplift under the steel lamellas and a belt adjusting to eliminate movement during cutting are part of the cutter. A hydraulic aggregate and a control panel with a switchboard are located next to the cutter. In case of maximum automation, a complete control system with a touch screen and visualization is delivered. The cutter construction frame can be fully or partially welded and joined with fitted bolts depending on the way of transportation and the cutter width.

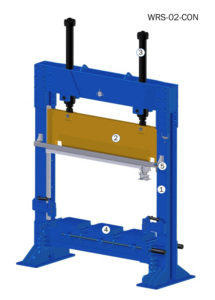

Main parts

- Machine frame (1)

- Knife body (2)

- Hydraulic cylinders (3)

- Prismatic bed (4)

- Automatic knife lubrication (5)

- Control panel and switchboard

Material

- The knife is made of machine tool steel

- The guiding is made of alloy hardened steel

- Other features are made of structural steel

Scope of delivery and accessories

- Complete machine according to main parts description

- Hydraulic aggregate

- Spare parts according to customer requirements

- Conveying system (belt conveyor with steel lamellas, two belt conveyor set that extends a stable bed of the cutter)

- Automatic knife lubrication

- Weighing equipment with a display

- Control panel and visualization

- Tilting and auxiliary table

Machine design and work safety are in compliance with the EU standards and EAC.

| Technical parameters | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Machine type | Parameters | A | B | C | D | E | F | H | ||

| WRS-01-CON | mm | 3 600 | 2000 | 2100 | 1500 | 5726 | 800 - 2 000 | 9 765 | ||

| WRS-01 | mm | 3600 | 2000 | 2100 | 1500 | 5063 | 800-2000 | 7 065 | ||

| WRS-02-CON | mm | 3 950 | 2 500 | 2 600 | 1 500 | 5 726 | 800 - 2 000 | 9 924 | ||

| WRS-02 | mm | 3 950 | 2 500 | 2 600 | 1 500 | 5 063 | 800 - 2 000 | 7 230 | ||

| WRS-03-CON | mm | 4 590 | 2 800 | 2 950 | 2 000 | 7 342 | 800 - 2 000 | 11 600 | ||

| WRS-03 | mm | 4 590 | 2 800 | 2 950 | 2 000 | 7 342 | 800 - 2 000 | 10 300 | ||

| Cutting force | kN | 600 - 1 200 | ||||||||

| Cutting speed | mm/sec. | 40 | ||||||||

| Reverse motion speed | mm/sec. | 20 | ||||||||

| Max. diameter of waste rol | mm | Reverse motion speed | ||||||||

-

Category

Cultural / Industrial Length

4 feetWidth

12 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]