Washing Separator VSV

Washing separators VSVare designed for deflaking, final screening and washing of rejects coming from primary cleaners in the waste paper processing lines. They run periodically in programmable mode with the following sequence: water inlet, stock processing, deflaking, washing and rejects discharge. It is not necessary to separate the washed rejects, it must be only thickened – e.g. on the vibrating screen.

Design

Washing separator VSV is as a standard, equipped with sorting screen PAPSCREEN, delivered with perforations of diameters 1.8, 2.2 and 2.5 mm. Separators are based on similar design concept and particular types differ from each other in the size of functional elements. The following types complete an integrated family:

- VSV-10 – functional elements Ć 400 mm

- VSV-20 – functional elements Ć 500 mm

- VSV-30 – functional elements Ć 600 mm

Installation of the screen “PAPSCREEN”

provides the following advantages, as compared to classical screen:

- Considerable increase of capacity

- Improved deflaking efficiency

- Higher screening quality by installing a screen with finer bores also for thick stocks

- Longer service life of screen and rotors

- Faster return on investment when upgrading waste paper processing lines

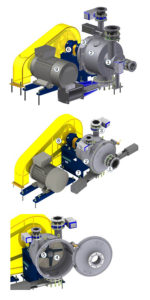

Main parts

- Input section working chambers (1) only in models VSV-10 and VSV-20; working chamber (2)

- Machine unit: output chamber (3),sealed with filling stuffing box

- Functional elements: screen (4) wiped by working and pumping rotor (5)

- Machine bedding (6)

- Stand (7)

- V-belt drive with a cover (8)

- Electric motor (9)

Material

- All parts coming in contact with the stock (input chamber, work chamber, machine unit) are made of stainless steel

- Other machine parts are made of structural steel with polyurethane coating

Accessories

- Input and rejects gate valve

- Outlet and dilution water valve

- Pneumatic distributor and control

Machine design and work safety are in compliance with the EU standards and EAC.

| Technical parameters | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| VSV-10 | VSV-20 | VSV-30 | ||||||||

| Input diameter | D1 | DN 100 | DN 150 | DN 200 | ||||||

| Output diameter | D2 | DN 100 | DN 100 | DN 150 | ||||||

| Rejects diameter | D3 | DN 200 | DN 250 | DN 250 | ||||||

| Dilution water diameter | D4 | DN 80 | DN 80 | DN 100 | ||||||

| Machine length (X) | mm | 1 732 | 1 640 | 2 480 | ||||||

| Machine height (Y) | mm | 1 000 | 1 100 | 1 250 | ||||||

| Machine height (Z) | mm | 1 480 | 1 710 | 1 820 | ||||||

| Capacity *) | tpd | 15 - 35 | 25 - 55 | 40 - 75 | ||||||

| Electric motor power | kW | 37 | 55 | 90 | ||||||

| Machine weight incl. drive | kg | 995 | 1 310 | 2 235 | ||||||

-

Category

Cultural / Industrial Length

4 feetWidth

12 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]