Vibrating screen

Vibrating screen VP Design is designed for screening in the lines processing chemical pulp, ground wood and waste paper where it is used mainly as an end part for final sorting of the reject from screening stages. An advantage of this screen is its open design; the stock can be seen while being screened. Another advantage is that the screen eliminates possible clogging as it happens with the closed systems. Sorting screen is provided with round bores of different sizes on the actual technological sorting requirements.

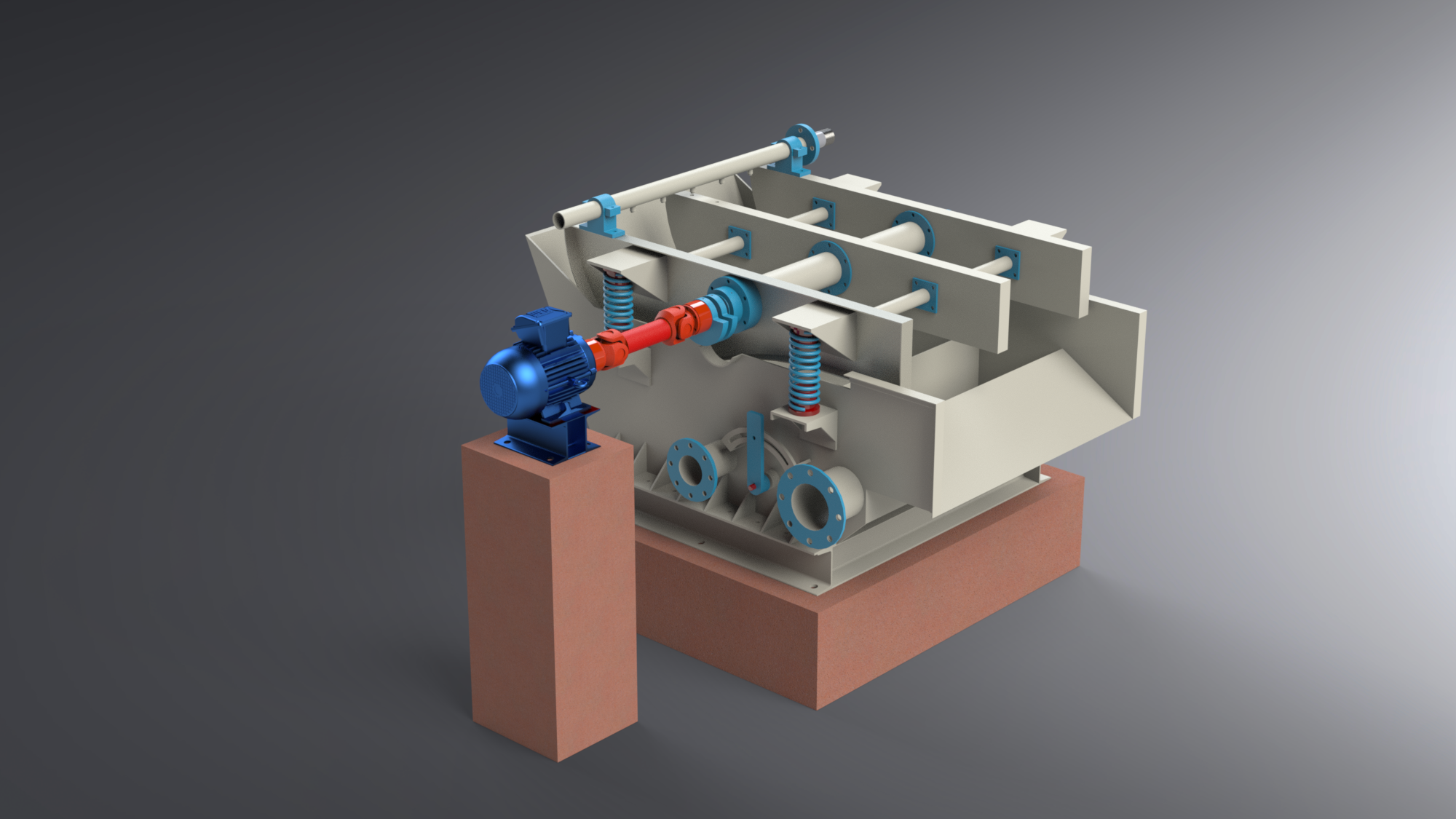

Design

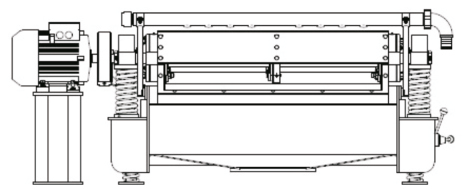

The vibrating screens can be anchored directly to a concrete floor or bolted to a steel frame. The vibrating screen itself consists of a tub that stands on anchor plates with springs. Those absorb the beats on the floor.

The screen with a vibrator is located on four springs hitched to the tub. The vibrator is driven by an electric motor using a V-belt. There is a shower pipe hitched to the tub as well. When operating, the vibrator sets the screen in a vibrating motion by a shaft with eccentrics. The stock flows on a screen and, using the vibrating motion, the accept goes through the screen into the tub, and the rest that cannot pass through the screen is moved upwards into a reject gutter. The screen reject is washed by the shower pipe on the screening part.

The impurities outlet, the accept outlet from the screen and its inlet on the screening part must be solved for each project separately depending on the screen location. These parts are not part of the equipment. The machine is equipped with a belt cover and eccentric cover.

Main parts

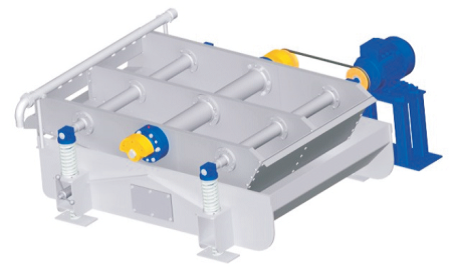

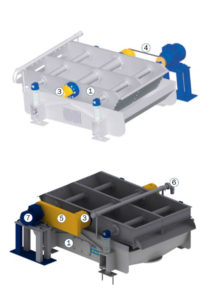

- Tub (1)

- Screen tank (2)

- Vibrator (3)

- Belt gear (4) with a cover (5)

- Shower pipe (6)

- Electric motor (7)

Material

- The tub, screening part and shower pipe are made of stainless steel

- The vibrator, drive stand and covers are made of structural steel and painted by a polyurethane double-component waterproof coating

Accessories

- Inlet reservoir with a gate valve

- Frequency converter

Machine design and work safety are in compliance with the EU standards and EAC.

| Technical parameters | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| VP-1-20 | ||||||||||

| Screen surface size | m2 | 1.57 | ||||||||

| Overall width with motor | mm | 2 050 | ||||||||

| Overall machine length | mm | 1 980 | ||||||||

| Max. machine height | mm | 810 | ||||||||

| Recommended consistency | % | 0.6 - 2 | ||||||||

| Screen bores diameter | mm | 1.8 - 3 | ||||||||

| Electric motor output | kW | 3 | ||||||||

| Electric motor speed | revs/min. | 1450 | ||||||||

| Machine weight | kg | 1000 | ||||||||

-

Category

Stock Preparation Section

Recycled OCC-DSOCC/White Waste/Mix Waste

Company Presentation

[elementor-template id="3268"]