Threading And Trimming Water Jet

Threading and trimming water jet is designed for trimming of paper web edges in the PM wire part and for making a tail for its threading in a PM press and drying parts. It is also used for fast paper web cutting in case of a web break. A standard design consists of one threading water jet (in case of the web break) and two trimming water jets. The possibility of dosing with automatic setting of the trimmed format (edges). Int this case the equipment consists of two jets, movable format one and movable threading-format one.

Threading water jet (in case of the web break) is controlled by an electric motor and an electromagnetic clutch with a possibility of a manual control by a hand wheel. It allows to thread the paper web from the PM wire part to the press part and to cut the paper web in case of its break. The threading tail width of the paper web can be set by means of inductive sensors as required. Trimming water jets are intended for a paper web trimming to a required size. They can be adjusted manually within a certain range.

Design

Basic part of threading and trimming water jet is formed by linear rails with a carriage. Threading and trimming water jet is attached to the carriage that can move on rails. It is driven by a toothed belt gearing and a worm-geared electric motor, coupled through an electromagnetic clutch intended for its uncoupling, if necessary. Threading and trimming water jet can be then controlled manually by a hand wheel. The feed rate can be regulated by a frequency converter depending on the PM operating speed.

The movement is monitored by four inductive sensors. Two of them are pre-set to the given threading tail width and the other two are used for protection in end positions. An electric control unit of the threading and trimming water jet is located according to customer’s requirements. Threading and trimming water jets are provided with removable nozzles with needle-shaped jet. The nozzles distance from the wire is to be set according to the given paper stock. Pressure water supply hose for the threading jet is placed inside of an energy chain. The whole equipment is mounted on stands on the main beams of the PM wire part.

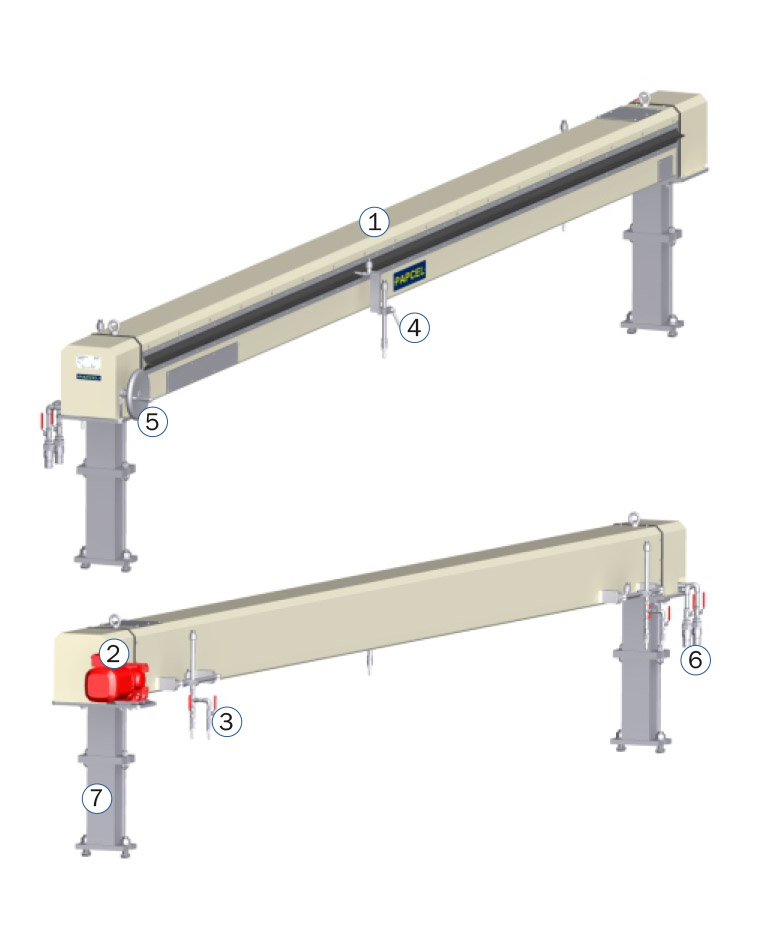

Main parts

- Linear guides – beam with V-belt pulleys and toothed belt (1)

- Worm gearbox (2); electromagnetic clutch „rotex”

- Trimming water jets (3)

- Threading water jet with a moveable carriage (4)

- Water distribution to threading and trimming water jet

- Manual drive (5), inductive sensors, guards (6)

- Stands with coupling to wire part (7)

Material

- Bearing structure and guards are made of stainless steel

- Linear rails – aluminium alloy and common steel

Scope of delivery

- Complete equipment according to main parts description

- Accessories optionally

| Technical parameters | ||

|---|---|---|

| Maximal paper width | mm | 7,000 |

| Maximal machine width | mm | 7,500 |

| Feed speed of threading water jet | adjustable by means of frequency converter upon customer's request | |

| Elektric motor | kW / W / rpm | 0.37 / 380 / 89 (resistant against wet conditions) |

| Adjustment of threading paper tail | mm | min. 80 / max. 500 |

| Adjustment of trimming water jet | mm | min. 0 / max. 270 |

Supply: clear industrial water – 2x pressure and consumption according to the produced material

-

Category

Cultural / Industrial Length

4 feetWidth

6 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]