Thermo Rolls Heating And Cooling Station

Heating and cooling thermo rolls for paper machine wide 3 m, roll temperature 200°C

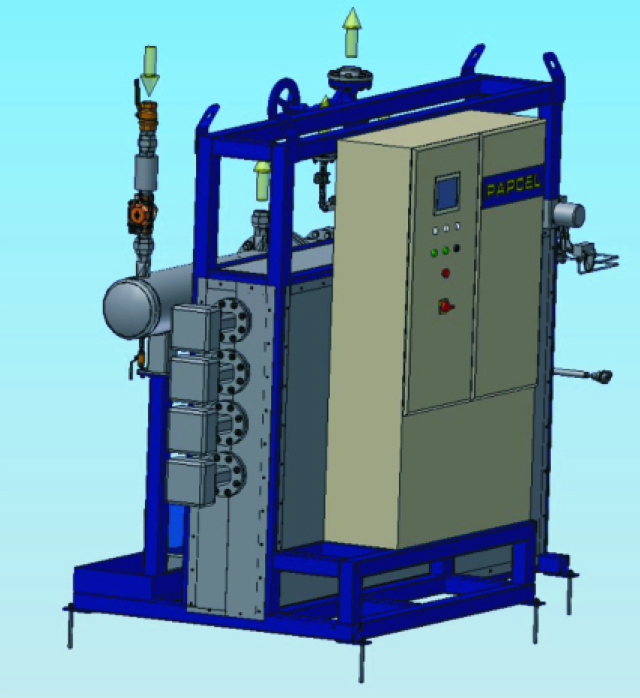

The station heats thermo oil for the thermo roll of the paper machine calender.Heating bodies built-in the station piping are used for heating; the body power feed input is 50 kW. The station is equipped with an electric switchbox, a pump and measuring & control (M&C) elements. Thermo oil is heated up to 200°C, the thermo roll temperature moves in the range from 90 to 170°C.

The equipment is delivered for paper machine calenders wide up to 10 m and paper machine speed up to 1 500 m/min.

Cooling

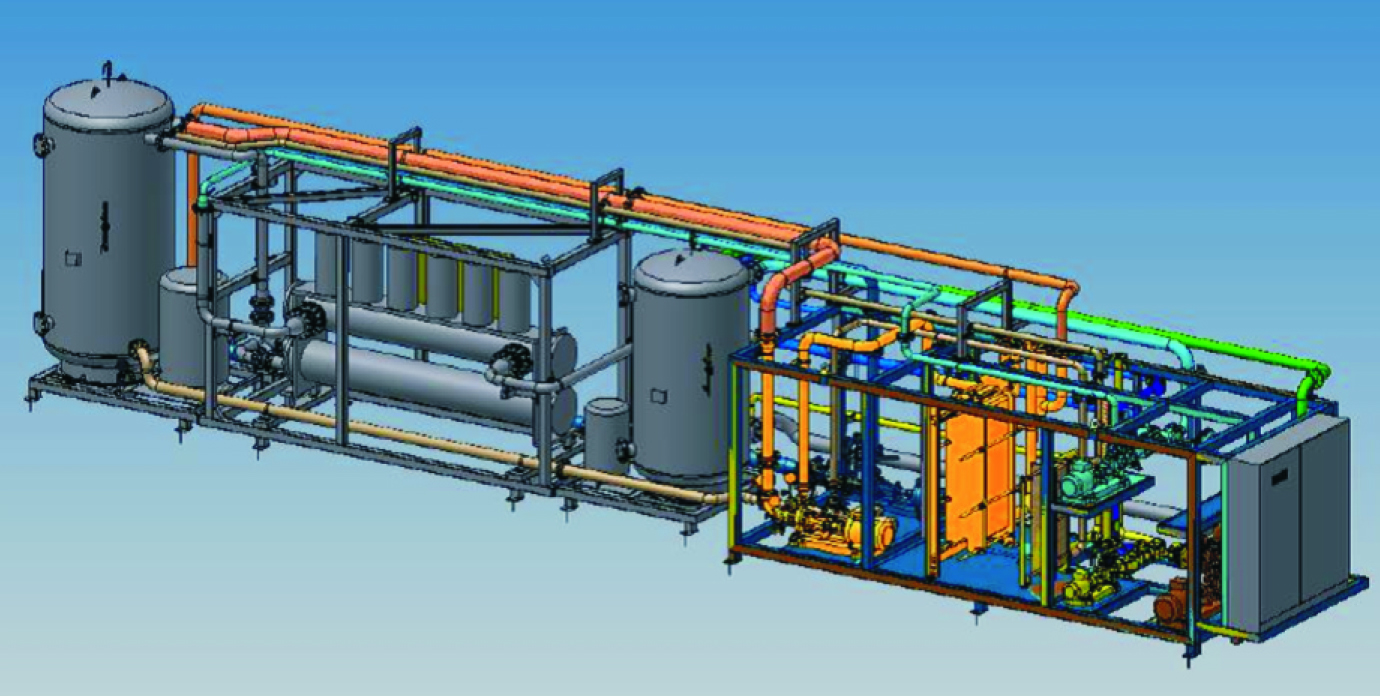

The cooling plant is divided into three compact units:

- Air pump cooling station

- Circulation unit

- Cooling tower

Heating options

- Gas up to 250°C

- Steam up to 140°C

- Electric power up to 300°C

The machinery design and safety comply with the EU and EAC industrial standards.

Heating thermo rolls for paper machine wide 3 m, roll temperature 200°C

Thermo oil is heated up to 220°C, the roll temperature is 200°C.

Heating options

- Gas up to 250°C

- Steam up to 140°C

- Electric power up to 300°C

Cooling

The cooling plant is divided into three compact units:

- Air pump cooling station

- Circulation unit

- Cooling tower

The equipment is delivered for paper machine calenders wide up to 10 m and paper machine speed up to 1,500 m/min.

The station includes

- Air pump

- Water storage tank with expander

- Glycol storage tank with expander

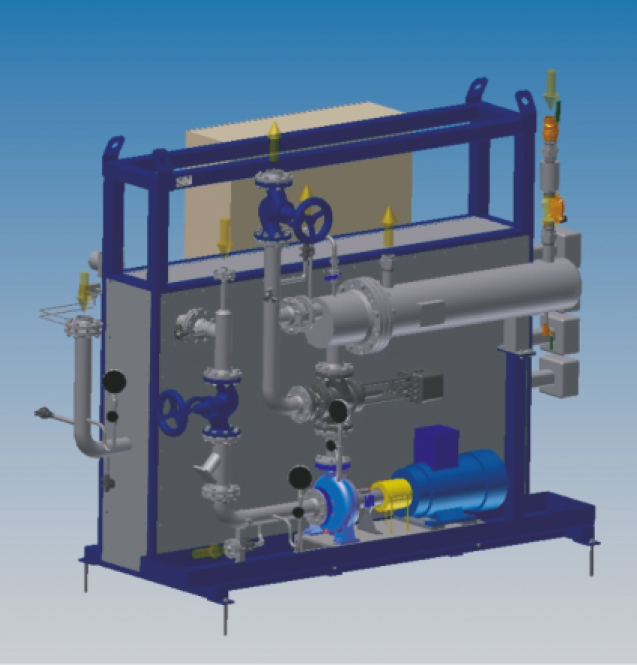

The unit includes pumps and heat exchangers. The station is designed for paper machine wide up to 3 m and speed up to 1,500 m/min.

Cooling water

From the storage tank is used in 3 circuits:

- Circuit for cooling water through an evaporiser water/glycol being part of the air pump

- Paper machine rolls cooling circuit

- Circuit of heat exchangers in an independent paper machine roll heating system; the system is not a necessary part of the equipment

Cooling water parameters:

- Fresh water source 3 to 5 bar – connection size G ¾”

- Storage tank with air tank 3 – approx. 2,900 dm

Cooling water

From the storage tank is used in 3 circuits:

- Circuit for cooling water through an evaporiser water/glycol being part of the air pump

- Paper machine rolls cooling circuit

- Circuit of heat exchangers in an independent paper machine roll heating system; the system is not a necessary part of the equipment

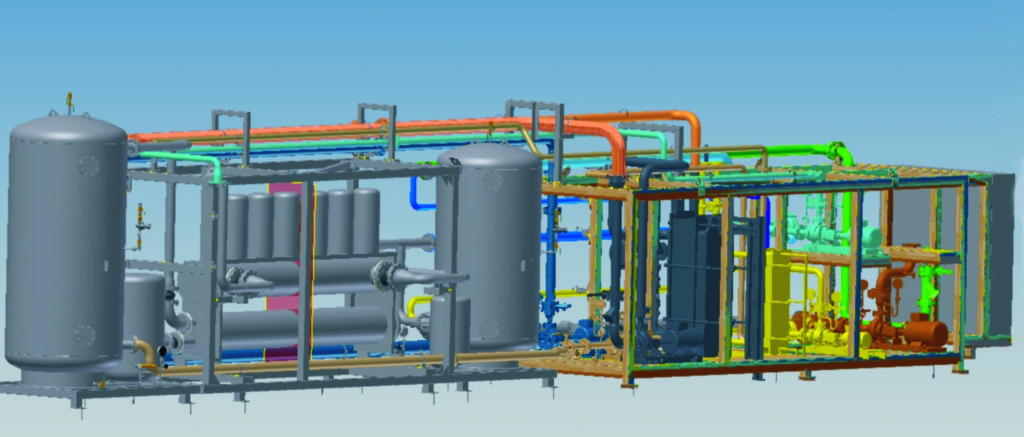

Glycol

From the storage tank is used in 3 circuits:

- Air pump circuit

- Plate-type exchanger circuit for warmed and cooling towers

- Plate-type exchanger circuit for paper machine rolls heating system

Glycol parameters:

- Source: commercial container – connection size G ¾”

- Storage tank with air tank 3 – approx. 4,200 dm

Warm water is used for cooling. Its source is another paper mill system.

Instrumental air for fittings drive

- Pressure 5 bar

- Consumption 20 dm /min

Unit main parts

- Air pump

- Exchanger 1

- Exchanger 2

- Dry exchanger

| Process parameters | ||

|---|---|---|

| Throughput: | 57 dm | |

| Oil temperature: | 200 C | |

| Power: | 220 kW | |

| Thermo oil: | Mobil 603 | |

| Heating: | electric coils | |

| Process parameters | ||

|---|---|---|

| Throughput: | 55 dm | |

| Oil temperature: | 200 C | |

| Power | 220 kW | |

| Thermo oil | Mobiltherm 603 | |

| Heating: | electric coils | |

-

Category

Cultural / Industrial Length

4 feetWidth

6 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]