For safe web threading through the drying section up to the reel at high-speed machinery, it is necessary to install a norope

threading syste.

It is based on utilisation of special doctors with air nozzles for feed tape routing between particular drying cylinders and on

the air or under-pressure conveyers. The most important part of this no-rope threading is a pneumatic system for control of particular nozzles in full-automatic sequence to optimize air consumption.

Utilization

- intended for high-speed machines (speed limit for rope threading is about 1.000 m/min)

- for machines with frequent changes in web width

- optimal linking to other threading elements in PM press and end parts (transfer rolls, air/vacuum, conveying systems)

- enhanced work safety

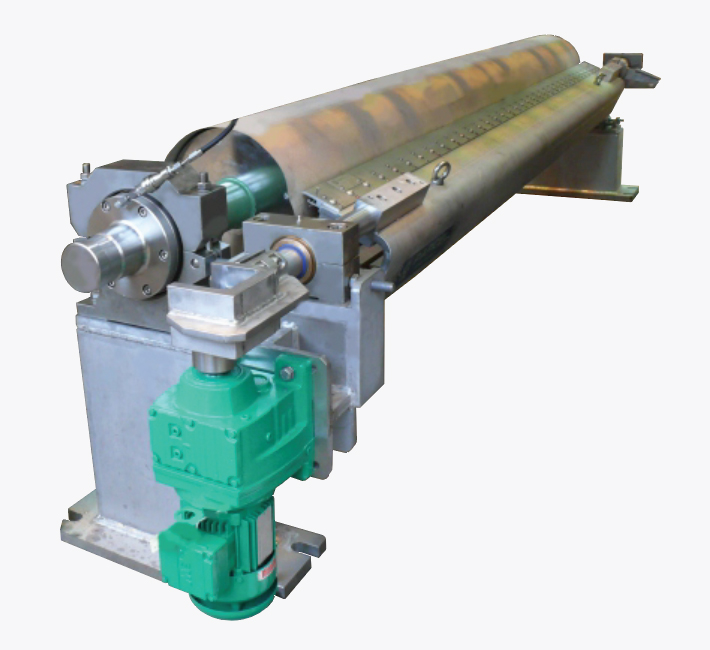

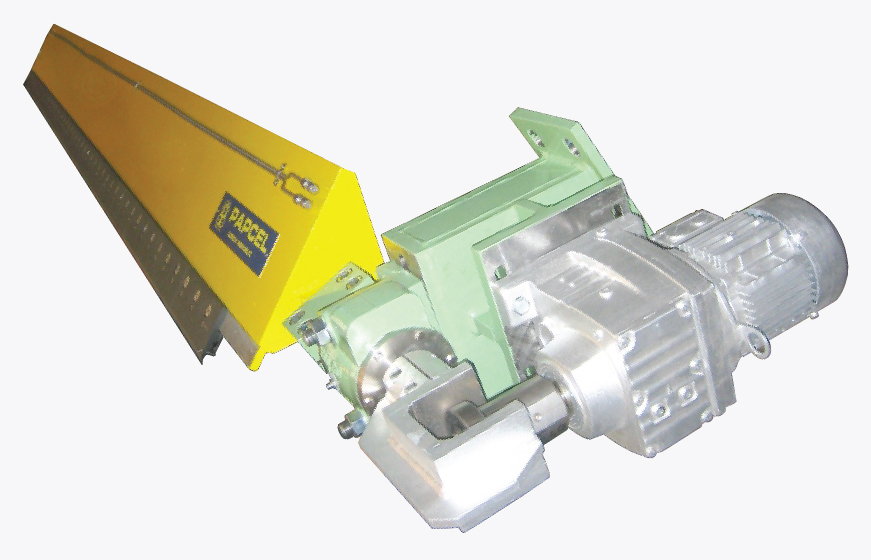

Air conveyer for feed tape routing

This equipment consists of stand, movable and stationary chute, blades with holders, rope pulleys, pneumatic cylinder, air nozzles and pneumatic control with master console. It is also equipped with guards and air vessel if required

Conveyer can be controlled by master console keys

- either manually, each function (functions in this mode are not conjugated)

- or semi-automatically (in this case functions are interconnected so that the real chute position defines operation of a certain nozzle etc.)

For its operation the conveyer requires touch-dry paper. Therefore it is installed usually for threading in the size press or film press (i.e. at the pre-drying part end) or in the calender and the reel (i.e. at the after-drying part end). In both cases the PM line runs with web dryness exceeding 90 %.

Construction design and machine safety are in compliance with EU and EAC standards.

Profukovací skříně pomocí proudu paprsku

Primary factors

- increased tension (web tension considerably reduces angle of web separation from roll)

- growing dryness (improved web strength characteristics with positive impacts on web separation from roll)

Additional factors

- PM speed (bigger angle of web separation from roll with growing speed)

- ratio air jet / wire (better web stretching brings lower angle of web separation from roll)

Secondary factors

- positive impacts on fine pulping quality