TCC Cookers For Native Starch Thermochemical Conversion

Continuous cooking thermochemically degraded native starch sorts in semi-automated or automated modes. The degrading agent is a strong oxidant, usually ammonium or sodium persulphates. The starch solutions prepared this way are suitable for usage as surface applications in size or film presses

Performance groups: TCC450,TCC1100

Performance range: 450to1100kg/hr

Slurry concentration: 22to28%

Power input: 2.2 to 8 kW

Function brief description

Powder starch is dosed by means of precise worm dosing device into a slurry tank where it is mixed with water and slurry is formed. The slurry concentration depends on a starch sort and use. Starch slurry is continuously pumped by means of a screw pump into a static mixer where saturated steam is injected into slurry. Before the steam inlet, the oxidizing agent is dosed into slurry in an exact ratio to starch.

That is the beginning of the cooking process being underway in a cooking tube following the mixer. The cooking temperature is set by means of control circuit on a preset value depending on the starchsort. The cooking tube is followed by another static mixer bringing diluting/cooling water into the cooked starch solution. The outlet concentration is controlled by means of dilution water quantity. Its through put is controlled by control circuit.

Starch diluted onto a required outlet concentration and cooled down to 60 to 85°C enters the storage tank and it is ready for further use. The process is identical for both cationic and oxidized starch. The oxidant dose controls the cooked starch final

viscosity

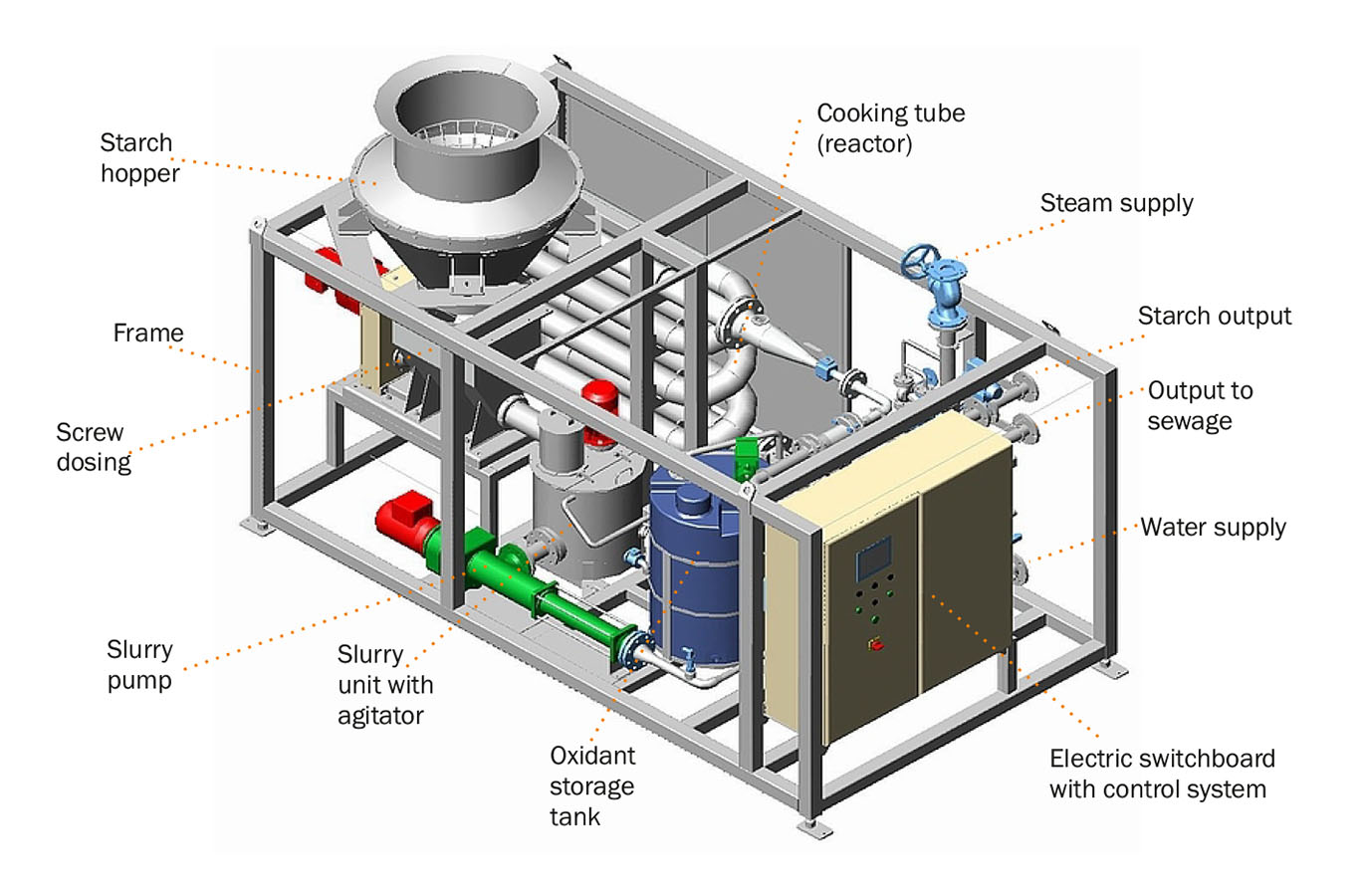

Cooker main parts

- Powder starch source – a hopper integrated in a support frame or certain type of a lowor high-volume silo for higher starch demand (the silo accessories are designed separately for particular applications)

- Precise worm dosing device with a drive and arms preventing a rising cavities

- Slurry tank with a high-performance agitator

- System controlling water throughput into the slurry tank-depends on the cooker type

- Slurry pump with or without performance control-depends on the cooker type

- Slurry filter screening coarse mechanical impurities

- Static mixer for steam injection

- Circuit for automatic cooking temperature control

- Cooking tube

- Static mixer for dilution/cooling water input

- Circuit for an automatic/manual dilution /cooling water throughput control

- Set of measuring & control elements

- Electric switchboard (wherever required)

- Support frame

- Device for preparation of oxidizing agent

Device for preparation of oxidizing agent

- Plastics (PP, PE) or AISI 304/316 grade stainless steel depending on the used product

- Dilution tank with agitator, integrated pumping chamber and measuring &

control(M&C)elements - Solution storage tank with accessories and M&C elements

- Precise diaphragm dosing pump with oxidant capacity control

- Dilution tank support frame (oxidant storage tank is installed in the cooker frame)

The machinery design and safety comply with the EU and EAC industrial standards.

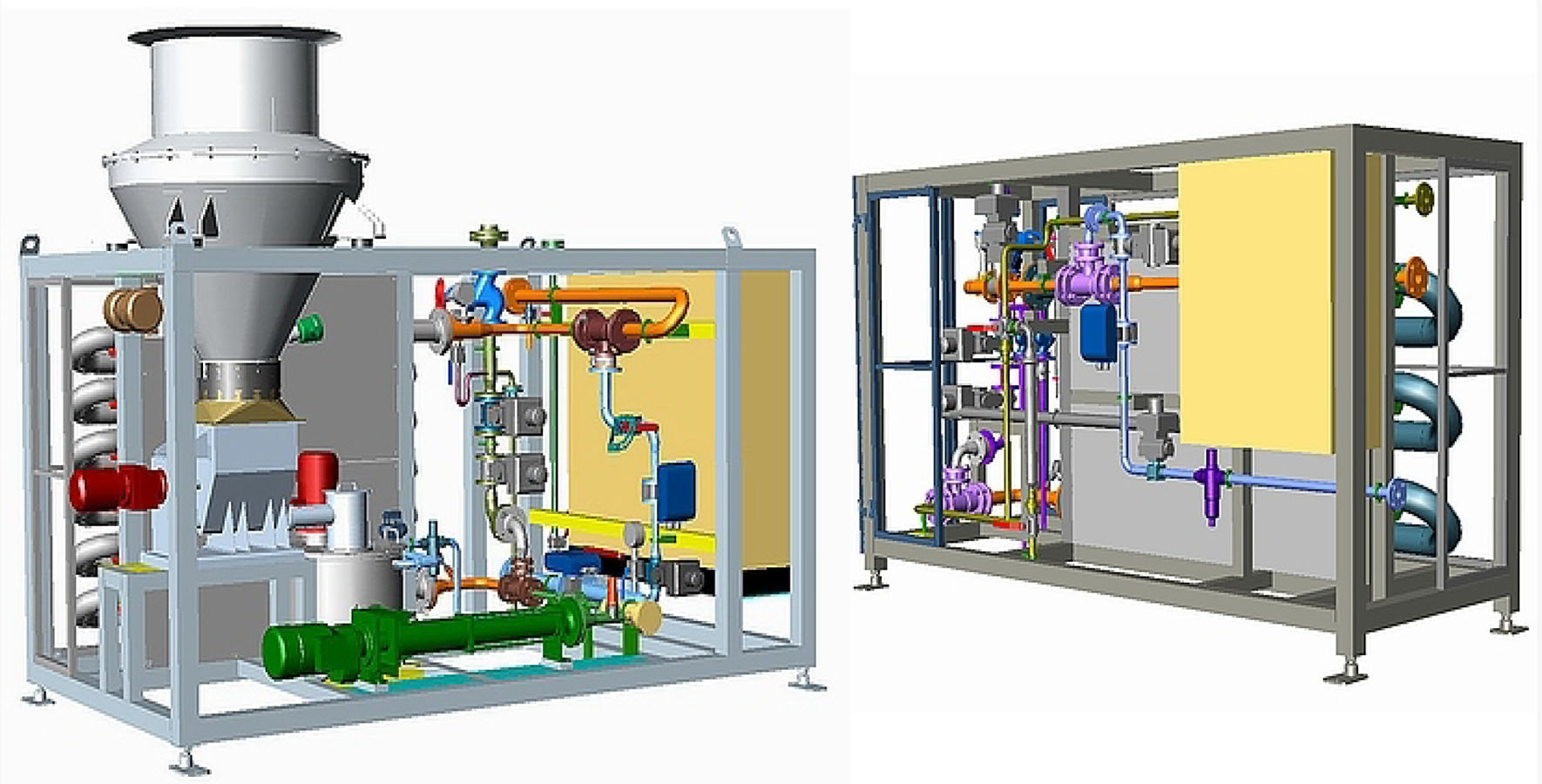

Cooker concept

K

Compact– slurry unit installed in the frame together with the cooking part

O

separate– slurry unit installed separately from the cooking part

Control system

–

none– – the cooker is controlled by means of an external control system

S

Simatic– the cooker is equipped with a PLC based on Simatic type S7

L

logo– the cooker is equipped with a simple programmable controller

Filling slurry tank with water

A

automatic– water throughput into the slurry tanks is controlled by an automatic control valve

P

float– water throughput into the slurry tank is controlled by a float valve

Slurry throughput control

F

frequency converter– the slurry pump is controlled by a frequency converter the slurry pump without a performance control

Back pressure control

A

automatic– the cooking tube pressure is controlled by an automatic control valve

M

manual– the cooking tube pressure is controlled by a manual valve

Dilution control

A

automatic– the dilution water flow through the cooking tube is controlled by an automatic control valve

M

manual– the dilution water flow through the cooking tube is controlled by a manual valve

Flushing

P

water for quick flushing is connected to the slurry pump suction side

–

flushing cooker enabled by water connected to the slurry tank

Cooker performance control

A

automatic– – the cooker works with a performance proportional control

–

the cooker works with a constant performance in an on/off mode

Starch hopper

N

– a starch hopper installed in the support frame is part of the cooker

–

no hopper, the starch source is a silo

Examples of TCC type cooker process diagrams with various starch filling modes

An example diagram of a TCC type cooker with an integrated hopper, with a slurry diluting water throughput controlled by means of an automatic control valve and an automatic control circuit with a control valve. An oxidant preparing and dosing system is included. The cooker is controlled by means of a Simatic based PLC.

Software

The TCC cookers are delivered including SW enabling a fully automated cooker operation in predefined steps – sequences. The sequences enable cooking and flushing automated modes at reproducible values before and after finishing the cooking process, including a precise oxidant dosing control. The cooker can be switched to a manual mode and the operation can be carried out by means of control board installed on the switchboard front door.

During the cooker operation the cooking process conditions like media parameters, functions and statuses of particular cooker key elements and control circuit statuses are monitored; if any parameter deviates from a control range an alarm message is generated and saved in an alarm bank. The system controls the oxidant preparation as well.

The cooker performance is usually controlled depending on the cooked starch storage tank level height either in an on/off mode (the cooker works with a constant performance, starts on the bottom level and stops after reaching the top level) or it works with a variable performance depending on the storage tank level fall speed.

Technical data

Starch sort: native

Starch origin: potato, corn, wheat, tapioca

Starch source: hopper integrated in the cooker support frame 3 (volume 100 to 400 dm )

Starch packing: paper sacks 25 to 40 kg “Big-Bags” 600 or 1 000 kg road tanker, starch stored in a high-capacity silo

Oxidant dosing: precise dosing pump with performance control and flow measuring

Cooking time: 4 minutes for all starch sorts

Heating medium: saturated steam 4 to 5 bar abs

Water: fresh or treated without mechanical impurities, minimum pressure 3.5 bar

Instrument air: dew point -20°C, pressure 5 bar

Performance change speed: dQ = 5 kg/min or a ramp change

An example of TCC cooker diagram filled from a medium silo, water throughput into the slurry tank controlled by an automatic control valve and an automatic control circuit with an automatic control valve. The system preparing and dosing oxidant is

included as well. The cooker is controlled by a Simatic based PLC.

An example of TCC cooker diagram filled from a large-volume silo, water throughput into the slurry tank controlled by an automatic control valve and an automatic control circuit with an automatic control valve. The system preparing and dosing oxidant is included as well. The slurry part is installed in a separate support frame below the silo output cone and connected to the cooking part by a pipeline. The cooker is controlled by a Simatic based PLC.

-

Category

Uncategorize Length

4 feetWidth

6 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]