Suction Tubes

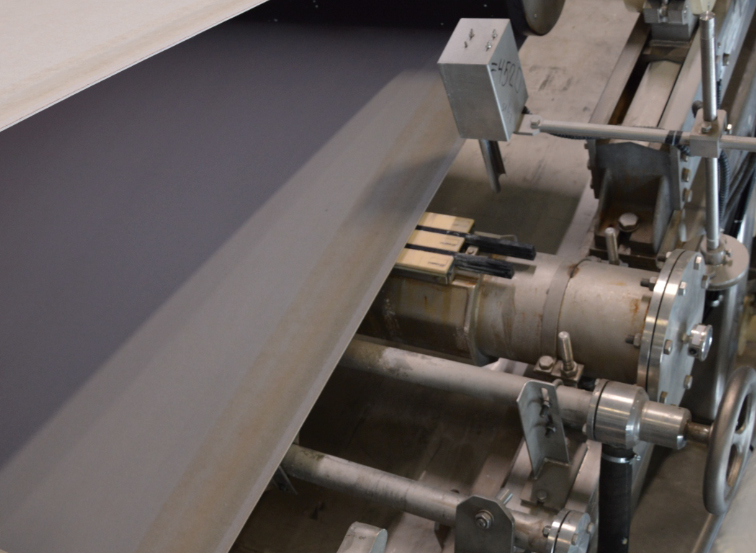

Suction tube is used for a mechanical or chemical cleaning of PM wires and felts. By means of an underpressure, it sucks out the given cleaning medium (water, chemicals) that is consequently led through suction piping outside the paper machine. This way of cleaning brings an increased quality of produced papers and at the same time a reduction of energy consumption and, last but not least, longer service life of wires and felts.

Design

Suction tubes can be produced in two modifications:

- Single or double grooved – for felt cleaning,

- Technological suction tubes – used for air extraction from the space between a paper web and the felt which brings an improved adhesion of the paper web on the felt.

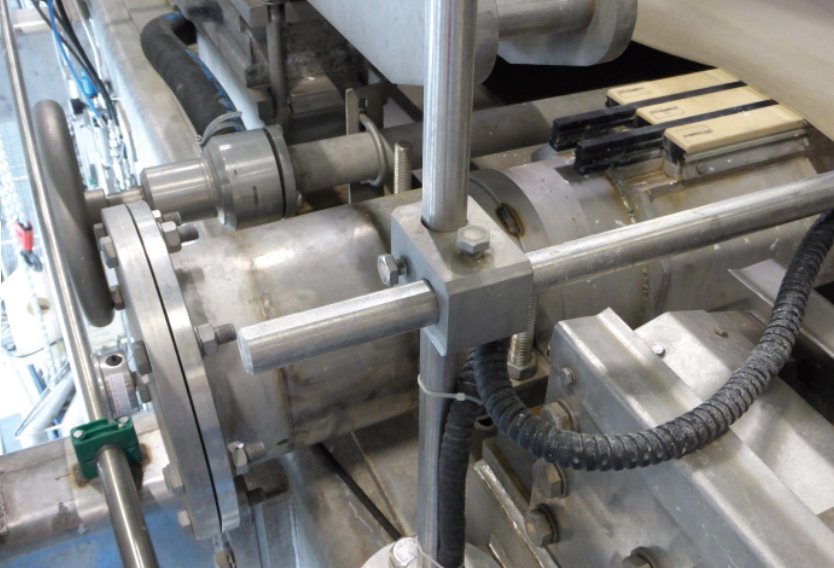

Felt suction tube is made of stainless steel, its lining can be made of plastics or ceramics. Suction tube is provided with an adjustable suction slot and adjustable suction width by means of sliding gates. On the control side, there is a blind flange with a vacuum meter; on the drive side, there is a flange for coupling of a pipeline to a vacuum pump.

The own body is bedded in split collars and attached to the bearing structure. It is height- adjustable in order to set its optimal position against the felt.

Suction tubes for cleaning are installed on felts or wires from the paper web side in places where there is no contact with the paper web. In case of permeable felts (1st press), there is a single, double or multi-grooved suction tube installed, for heavier felts (2nd and 3rd press), we recommend to use two suction tubes installed in series where a spacing between them should not exceed 0.5 m.

Technological suction tube is used especially in the press part in front of a nip of the actual press. When touching the felt, the paper web can close up a certain part of the air which, after going through the nip, causes paper web breaks or a paper web fold. These defects are prevented by the technological suction tube that sucks the unwanted air through the felt. The structural design of the tube depends on its position. When placed very close to the nip, the suction tube with a „nose” shape is used. In case of a longer distance from the nip, the shape of the suction tube can match the suction tube used for a felt conditioning.

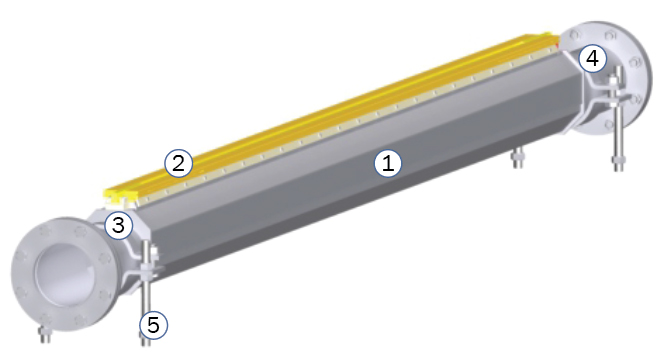

Main parts

- Suction tube body (1)

- Suction tube lining (2), sliding gates (3)

- Blind flange with vacuum meter (4)

- Rotary flange on drive side (5)

- Bolts for attachment to bearing structure

Material

- Suction tube body, incl. flange is made of stainless steel

- Suction tube lining – polyethylene, ceramics

- Sliding gates – polyethylene

Scope of delivery

- Complete device according to main parts description

- We deliver a flange joint including a counter flange and edging ring

Accessories

- Separator, hoses

Cross-section areas

- Cross-section area of single-grooved suction tube: 80 – 100 % of open slot area

- Cross-section area of double-grooved suction tube: 100 – 150 % of open slot area

- Cross-section area of suction piping: 70 % of open slot area

Machine design and work safety are in compliance with EU and EAC standards.

| Technical Parameters | ||

|---|---|---|

| Suction slot width | mm | 8 - 15 |

| Underpressure | bar | 0.2 - 0.4 |

-

Category

Cultural / Industrial Length

4 feetWidth

6 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]