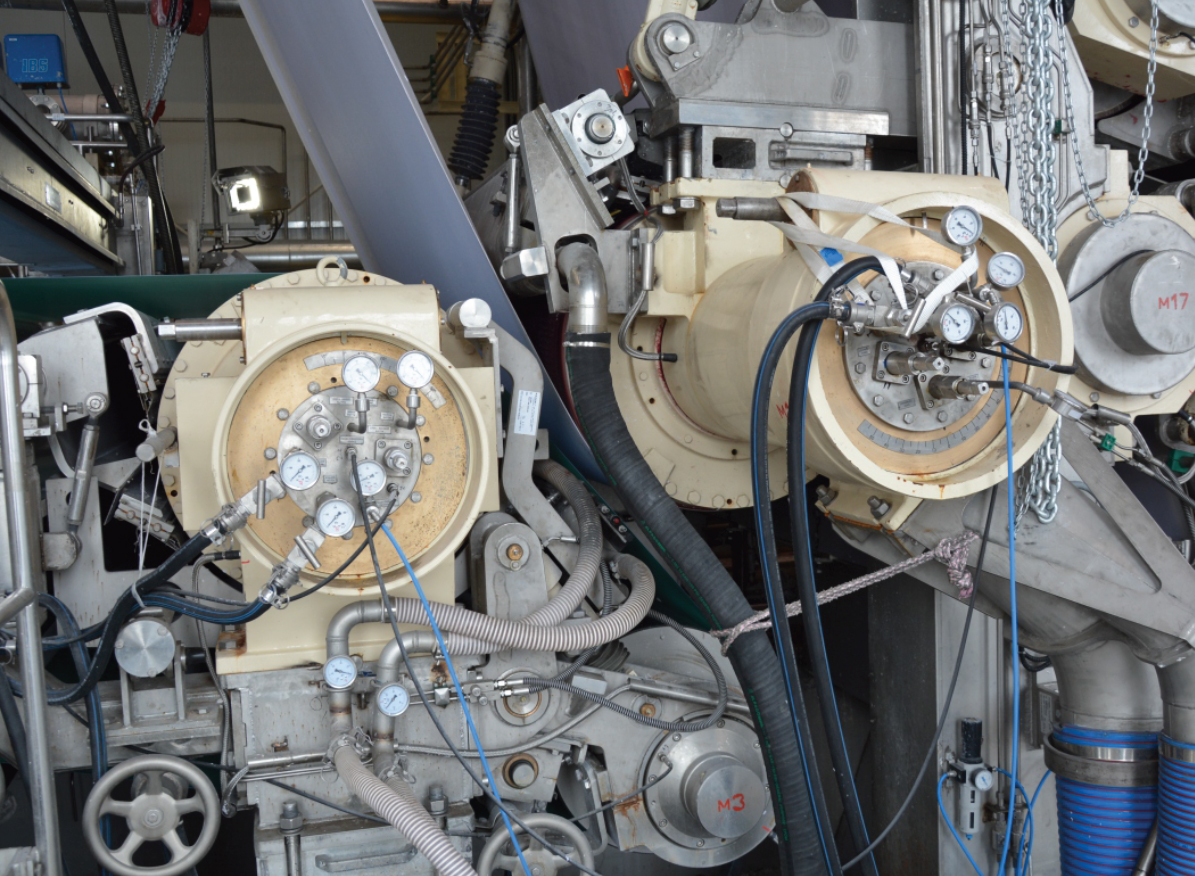

Suction Roll

Suction rolls are generally used in the PM wire part (wire suction roll) and in the PM press part (pick-up roll, felt suction roll, press suction roll).

Design

Depending on their usage suction rolls are produced in one-, two- or three-chamber design. The three-chamber rolls are used for transfer of the paper web from the wire part to the press part (pick-up). The body is made of a bronze or stainless tube. The roll chamber is welded from stainless material. These rolls are available with diameters up to 1.200 mm, length up to 5 m and max. pressure of 60 kN/m.

Main parts

- Roll surfaceChamber

- Bearing bodies (on operating side langed for connection to vacuum source)

- Slides for suction width adjustment

- Inner shower for slides lubrication

- Worm gear for roll chamber adjustment to functional position

- Air distribution for slides load control

Material

- Upon customer’s request

- According to load

The rolls are supplied with coatings and blankets

- Grubber or polyurethane, Teflon, copper-plated, ceramics, chrome- plated or plasma-sprayed (stainless steel, type 13 % Cr, chromium-nickel, chromium-nickel-molybdenum, wol- ram-carbide etc.), i.e. according to customer’s requirements

- U blind-bored or grooved rolls available, or their combinations, as required for particular blankets

Scope of deliveries optionally includes special roll blankets from our reputable suppliers in case of previous agreement with the customer.

Service

For all the rolls mentioned above, we can provide repairs, overhauls, replacement of roll necks and also coating of necks, grinding of roll surfaces and new blankets. This service is offered completely, i.e. from dismantling of the roll out of the machine through overhauling to its reassembly. For all the rolls, we can produce and deliver also beddings both for grease and oil lubrication.

Construction design and machine safety are in compliance with EU and EAC standards.

-

Category

Cultural / Industrial Length

4 feetWidth

6 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]