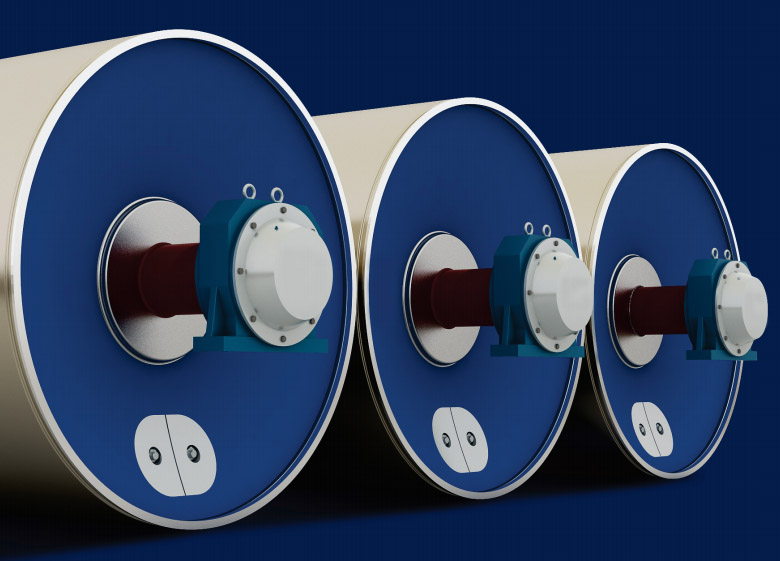

Steel Dryers

Material Properties

Since steel is a stronger material and has a modulus of elasticity which is considerably more than 2.1 times higher than cast iron, while designing the pressure vessel safety codes allow for better design parameters on steel. The much higher allowable stresses for steel mean that the shell wall can be thinner, which gives the positive benefit of higher heat transfer rates.

Lower shell root thickness for steel means the resulting heat flow is higher through the cylinder. This gives a higher evaporation rate which can flexibly either be used: to increase the production rate at constant energy input or, when the machine speed is kept constant, to reduce the drying energy.

Furthermore, during casting, pinholes are often developed in body, which need to be filled or repaired; otherwise, these create different quality issues on paper. Such an issue is never seen in steel dryers.

It is interesting to note that CI has a better compressive strength compared to steel, and that makes it more suitable for compressive loads like machine framings, sole plates, base plates etc. Probably, this is the reason that many old papermakers still consider CI a better option than steel. However, the ultimate tensile strength of steel is much higher (even 4 times) than that of CI. To add further to it, one must also keep in mind that specially developed high strength steels now have even more strength than the conventional ones.

Higher heat transfer and lower energy costs

Cast iron and steel have essentially comparable thermal conductivity, so as the shell is thinner, better heat transfer can be assured.

Another benefit of the reduced shell thickness and higher heat transfer is that lower steam pressure can be used for drying. In such a case, the same production rate can be reached using lower steam pressure with higher Latent Heat of Vaporization.

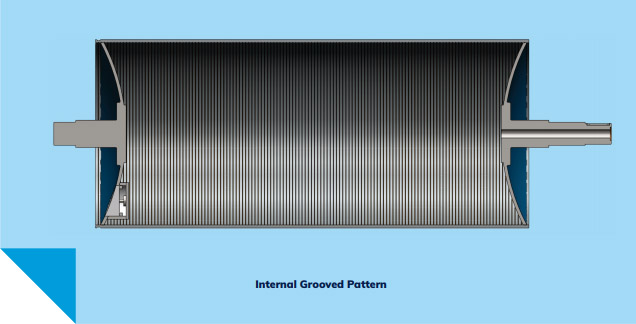

With the grooving inside the shell, overall heating area is considerably increased resulting in better conductivity. The result is lower total energy consumption. Depending on the cost ratio between the different energy sources, significant energy cost savings are possible in tissue machine with fabricated dryers, in fact the energy cost shall be lower in steel Drying Cylinders compared to a C.I. one. The investment cost for steel cylinders are also favorable while compare to the cast iron variety, and the physical weight is also less as well helps less engine power consumption.

Automation, today, is considered the most significant part of any process. Having a dryer of lesser thickness means having lesser heat capacity of the dryer, which leads to faster and efficient control. Hence, you can see better and quicker response to your actions (change in set point of dryer steam pressure, resulting in change in paper moisture). This results in better quality and quality consistency of paper being produced. Not only this, this also results in quicker start-up of the machine after a long stoppage, like a wire/felt change.

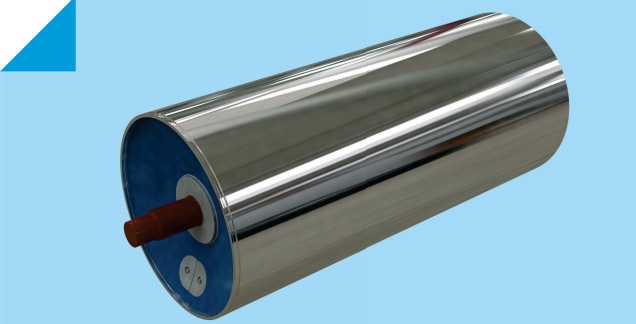

Metalizing benefits on carbon steel yankee

It should be mentioned that steel Yankee & dryers can be metalized prior to increase the surface hardness, life and water resistance. Metallization eliminates the need for re-grinding of the shell wall base metal, which on cast iron can eventually result in de-rating. Metallization is also a key reason that steel Yankees are far less prone to developing chatter problems.

Safety

Safety is of course a very prime factor for consideration for all organizations of the industry. Failure with Explosions on cast iron drying cylinders unfortunately have sometimes happened due to the poor material properties & brittleness of cast iron. Thus the cylinder can explode due to excess pressure, loaded with excessive load, or in case of an accident for other reasons. Steel, on the other hand, will have a better performance in the event that internal stresses exceed than allowable limits.

In the event that internal stresses on the steel shell exceed the yield strength, the steel shell may deform but stay intact.

If the stresses inside a cast iron dryer exceed the yield strength, the dryer may explode.

| Sizes can be offered | ||

|---|---|---|

| Diameter | Face Length | Remark |

| Drying Cylinder | ||

| 1220 mm OR 4 Feet | Up to 5.1 mtr. | with internal machining and Grooving |

| 1500 mm OR 5 Feet | Up to 5.1 mtr. | with internal machining and Grooving |

| 1800 mm OR 6 Feet | Up to 5.1 mtr. | with internal machining and Grooving |

| 2100 mm OR 7 Feet | Up to 5.1 mtr. | with internal machining and Grooving |

| Yankee Cylinder | ||

| 10 Feet Dia (3048 mm) | Up to 5.1 mtr. | w/o internal machining and Grooving |

| 12 Feet Dia (3658 mm) | Up to 5.1 mtr. | w/o internal machining and Grooving |

| 14 Feet Dia (4267 mm) | Up to 5.1 mtr. | w/o internal machining and Grooving |

| 16 Feet Dia (4876 mm) | Up to 5.1 mtr. | w/o internal machining and Grooving |

| 18 Feet Dia (5486 mm) | Up to 5.1 mtr. | w/o internal machining and Grooving |

Summery

In summary, steel Dryers have major advantages compared with cast iron in terms of Productivity & Safety matters, and also in energy costs due. Steel fabricated Dryers therefore offer potential energy cost savings, while also having a lower capital investment cost than cast iron.

Substantial field data available today from our experience and client relations for Steel Dryer applications has led to technological and manufacturing process guiding principles. The use of steel instead of cast iron allows a significant reduction in shell thickness which decreases thermal resistance and thus increases heat transfer.

The result is higher drying capacity achieved by increased steam condensation inside the dryer. Data obtained from Steel Dryer installations have confirmed that the heat exchange coefficient and the drying capacity of Steel Dryers typically exceed those of cast iron occasionally by 30% given the same dimensions and operating pressures. Experience gained from market installations and looking to the current market trend ‘VOCAL FOR LOCAL’ have led us to implement an improved rib design in the second generation Carbon Steel fabricate Drying Cylinders – MADE IN INDIA.

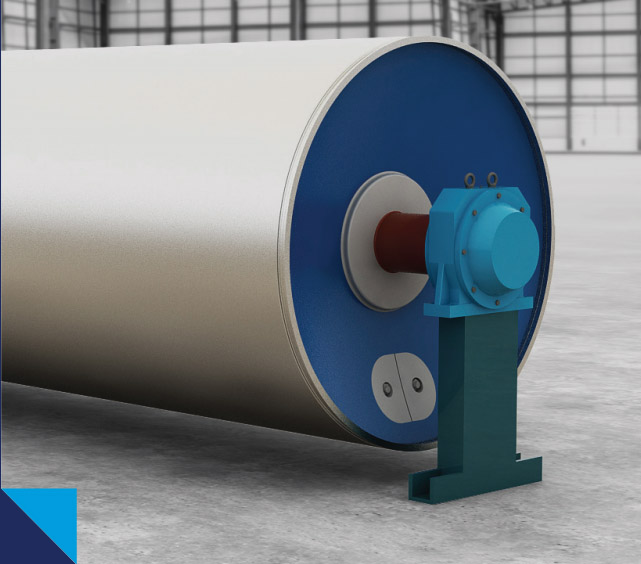

The Steel Dryers are no longer just considered for slow and economical machines. Now Steel Dryers are capable of reaching high speeds and can be supplied with features of,

- Internal machining to provide even thickness of the Shell.

- Minimize or Zero unbalance of Shell due to both side machining.

- Even heat exchange due to even shell thickness and more heating area due to spirally ribbed internal surface.

- Composite unit of Alloy steel cast shaft with side disc (Single piece Cast), Welded at both end to avoid any kind of shearing/ breakage of shaft from side disc welded joint.

- Precisely balance as per G 2.5 for High Speed application.

- Surface Mirror finish up to 0.6 to 0.9 micron.

- Prepared from specially ordered steel plated from reputed suppliers.

Upon material procurement & manufacturing and completion each Fabricated Dryer is thoroughly inspected with 100% Ultrasonic and Magnetic testing of all components. Phased Array and 100% X-ray inspection are also performed on all structural welds. Dimensional and pressure tests are performed before the final approval of the cylinder. Stress reliving before machining is also an optional feature available with us.

- Prev

- Prev

- Next

-

Category

Paper Machine Section

IndustrialPaper/CulturalPaper/SpecialtyPaper

Company Presentation

[elementor-template id="3268"][elementor-template id=”3444″]