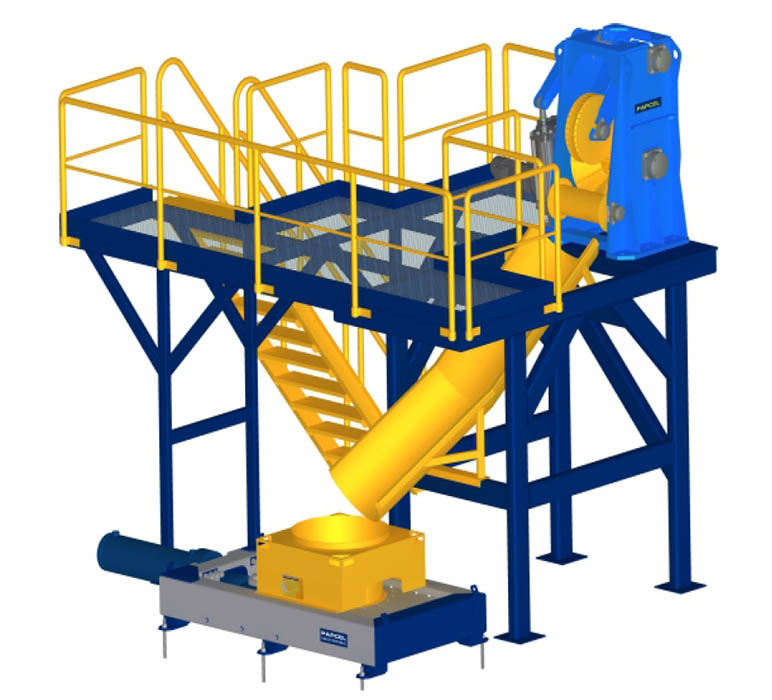

Spinning Impurities Ragger

Spinning impurities ragger SN is designed for drawing spinning impurities out of a pulper tank, particularly during waste paper pulping. The machine is recommended only for continuously working pulpers. To create pulper tail a sufficient quantity of spinning impurities, such as strands, rags, wires, synthetic foils, etc., is needed.

Design

The ragger frame is anchored by six anchoring bolts. At the bottom part, there is a driven shaft; a spiked pulley is mounted on its end. This pulley is driven by an electric motor with a gearbox. The loading pulley is pivoted in the top part of the frame. Its swinging is controlled by a pneumatic cylinder attached to the frame. Down pressure of the pulley on the tangle is implemented in two stages: basic and increased pressure. The quantity of spinning impurities being drawn out depends on the stock contamination rate. The operating speed of the ragger can be regulated depending on quantity of impurities to keep the tangle diameter within a range of 100 to 300 mm or 450 mm according to the ragger type. For the tangle creation, it is necessary to have a sufficient quantity of spinning impurities in the charged material.

For example, cores and cardboards of bigger sizes bring negative impact on creation and drawing tangle as they entangle in a tangle that cannot pass through an output branch. The impurities outlet, the accept outlet from the screen and its inlet on the screening part must be solved for each project separately depending on the screen location. These parts are not part of the equipment. The machine is equipped with a belt cover and eccentric cover.

Main parts

- Machine frame (1)

- Drive pulley (2)

- Downforce pulley (3)

- Output pulley (4)

- Pneumatic cylinder (5)

- Electric gearbox (6)

- Control switchboard (is included in the accessories)

Material

- The machine is made of structural steel

- Exposed parts are made of special high-grade steels

- External surfaces are protected against corrosion with a high-quality coating

Machine design and work safety are in compliance with the EU standards and EAC.

| Technical parameters | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SN-12 | SN-13 | |||||||||

| Max. dragging force | N | 19 200 | 25 800 | |||||||

| Max. pulper tail diameter, which can pass through | mm | 300 | 450 | |||||||

| Min. pulper tail diameter | mm | 60 | 60 | |||||||

| Max. shifting speed | m/min | 1.45 | 1.45 | |||||||

| Machine weight | kg | 1450 | 1 633 | |||||||

| Electric motor output | kW | 0.55 | 0.75 | |||||||

-

Category

Cultural / Industrial Length

4 feetWidth

12 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]