Soft Calender

Soft calender is a machine usually installed at the PM line end before the reel. It is designed for onesided or both-sided glazing of paper webs for production of fancy and graphic papers. There is a steam box installed before the calender which provides improved smoothness of the paper surface.

Design

The soft calender is standardly produced as a four-roll two-NIP press or as a double-NIP with three rolls. Each NIP provides combination of an oil-heated thermo roll and a swimming S-roll with a continuously adjustable bending according to the actually induced load.

At one-sided web glazing, both rolls are placed either up or down according to the side being glazed.

At double-sided web glazing, the thermo roll is placed up in the first NIP and down in the second NIP.

Each roll is equipped with a swinging doctor. Swimming roll edges are monitored by thermocameras that provide signals for cooling of surfaces in question to keep their temperatures constant and to reduce the temperature of the roll cover in order to assure its longer service life. Before each pressing zone, there is a spreader roll providing optimal transverse tension of the paper web. The paper web, leaving the PM drying part, goes through a steam box to the first spreader roll providing the cross web stretching before its entry in the first NIP. Afterwards, the paper web goes over its web guiding roll to the second spreader roll where it is stretched before its entry into the second NIP.

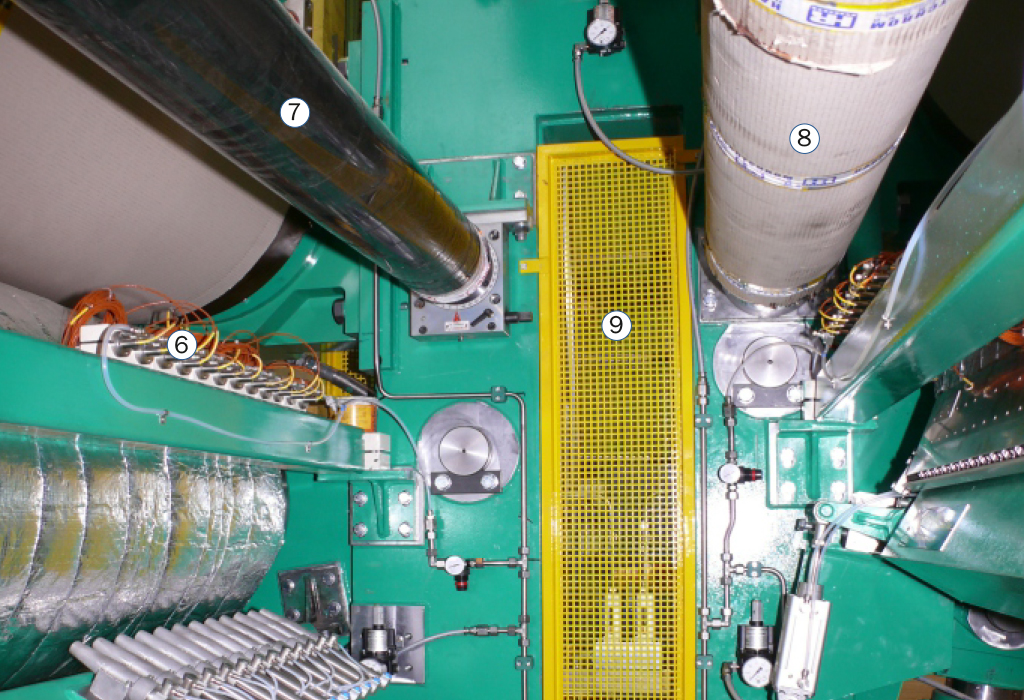

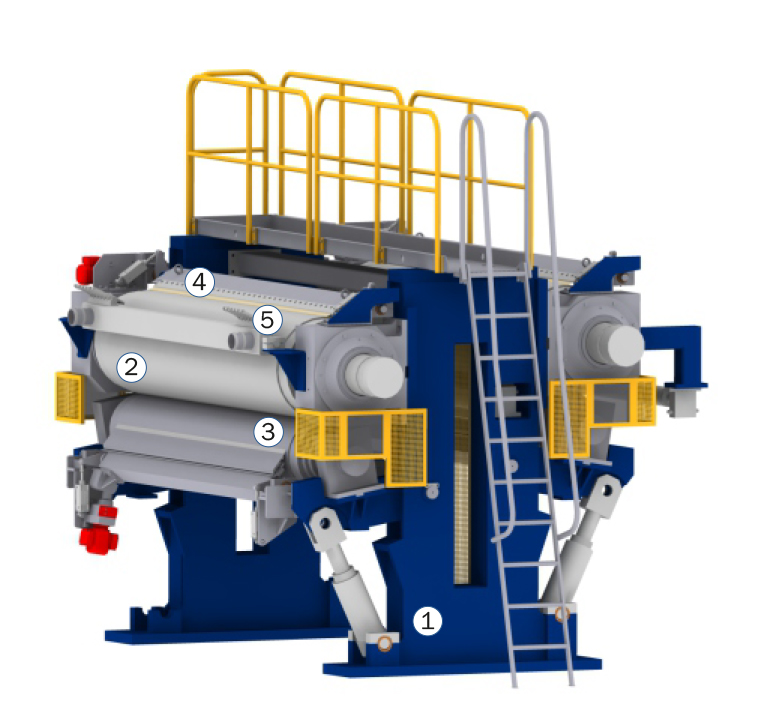

Main parts

- Supporting structure (1)

- Thermo-roll (2), S-roll (swimming roll) (3)

- Swinging doctors (4)

- Roll edge cooling system (5)

- Temperature measuring elements (6); enter elements for dissipation of static electricity

- Spreader roll (7), web guiding roll with bedding (8)

- Web tension sensing system; hydrostatic drive

- Pneumatic distribution line

- Machine covers (9)

Accessories

- Air distribution elements with fan for roll edge cooling

- Heating station of thermo rolls

- Soft calender drive and steam box

Scope of delivery

- Machine in accordance with main parts description

- Accessories optionally

Supporting structure

Through its design this supporting structure, comprising particular stands made of structural steel, minimises operating vibrations. Individual stands are mounted to each other by strengthened bolt connections and adapted to provide safety handling during on-site installation by a crane or other lifting devices. This supporting structure is designed to provide maximum machine rigidity both at standstill and running.

Thermo-rolls

The soft calender is equipped with two thermo rolls that can be heated up to 180 C. The roll surface is protected with a special cover to provide an optimal paper web smoothness. Both thermo rolls are put in bearing bodies with a spherical roller bearing on the drive side and with a roller bearing, type CARB, on the operating side. All bearings of the thermo-rolls are lubricated through a central lubrication system.

S-roll (swimming roll)

The soft calender is equipped with two S-rolls with coating. Each S-roll is powered by toothed belts being stretched by a bolt. Its pinion is bedded in a bearing body equipped with two spherical roller bearings.

Oscillating doctors

Oscillating doctors are designed for surface cleaning of thermo-rolls and floating rolls. Their oscillating motion is based on shearing actions of the doctor blade across the roll surface. The total travel (stroke) is 19 mm at frequency of 12 cycles/min. Any regular motion of a doctor brings improved doctoring and removal of particles settled between the blade and the roll. Concurrently, it eliminates possible roll surface damage. This swinging motion is induced by an electric front gearbox.

Roll edge cooling system

This system is designed for S-roll edge cooling in order to avoid different temperatures on the roll cover due to contacts between the paper web and the thermo-roll. This roll edge cooling system comprises two fans that can be switched independently or concurrently as necessary. Behind the fans there are a water cooler and distribution piping of individual beams.

There are blowers (air nozzles) on these beams installed with pneumatic cylinders used for opening or closing of the air supply line according to the actual S-roll surface temperature.

Temperature measuring elements

Due to different temperatures on the S-roll cover resulting from the contact between the paper web and the thermo-roll, it is necessary to monitor the zone in question. Therefore, the cross beam is provided with thermo-cameras.

Elements for dissipation of static electricity

A discharge electrode is used for active discharging of electrostatic faults during production and they work with voltage of 8 kV AC. Because of various profiles of surface charges, the electrodes are designed for charges of both polarities. The discharge electrode is connected to a highvoltage power-supply unit.

Spreader roll

This spreader roll is intended for paper web stretching in its cross direction before its entering the soft calender pressing zone. An actual roll deflection can be adjusted by means of a worm gear.

Web guiding roll with bedding

The paper web guiding roll is attached to the calender´s supporting structure. It is designed for paper web guiding from the first NIP toward the spreader roll. The roll surface is chrome-plated and the chrome layer thickness is up to 80 μm.

Web tension sensing system

The system comprises tensometric sensors installed under the web guiding roll beddings, located in front of and behind the soft calender. The sensors are used for a web tension evaluation and adjustment.

| Technical parameters | ||

|---|---|---|

| Operating speede | m/min | 1,500 |

| Linear pressure | kN/m | 300 |

| Maximal web width | mm | 7,500 |

| Thermo-rolls diameter | mm | 710 |

| S-rolls diameter | mm | 555 |

| Termo-roll temperature | oC | 180 / 230 |

-

Category

Paper Machine Section

IndustrialPaper/CulturalPaper/SpecialtyPaper

Company Presentation

[elementor-template id="3268"]