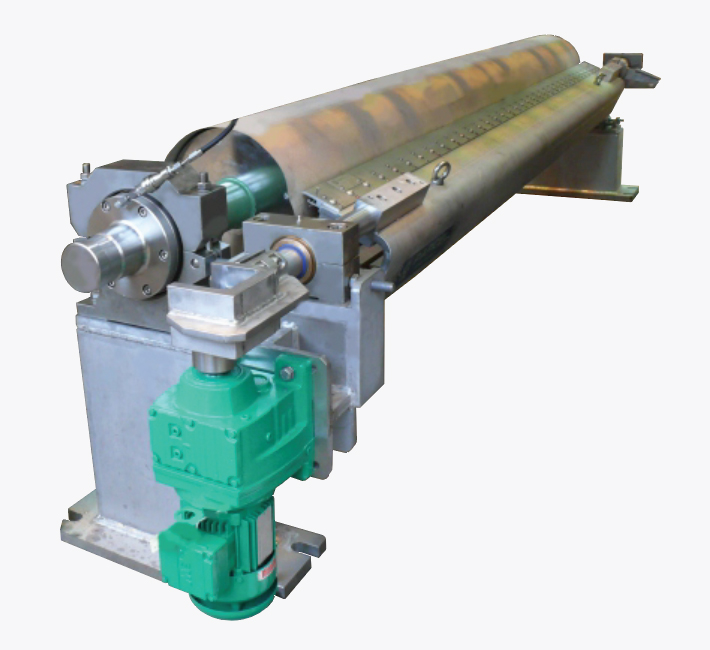

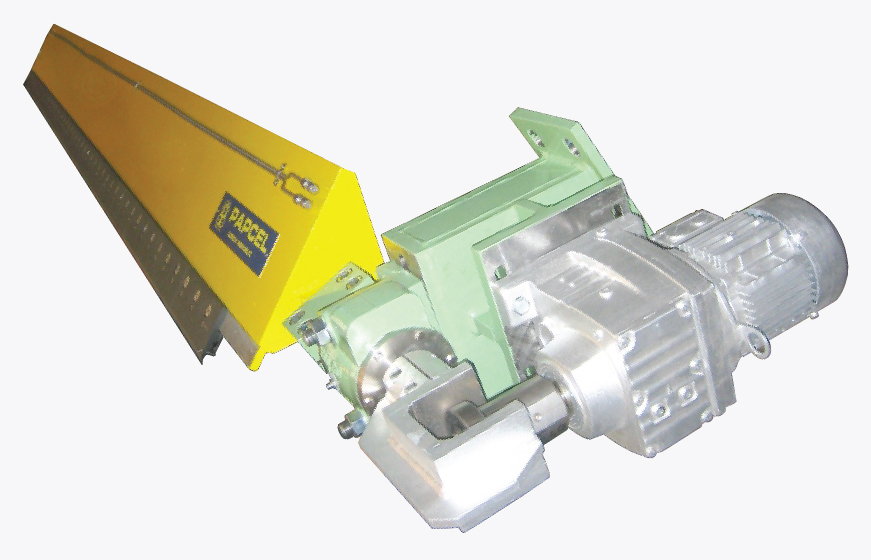

Size Press Workstations

Size press workstations are designed for paper machines with the output of 1 to 30 tph. Their design enables to colour starch for one- or two-side test liner colour coating.

With regards to that the concepts are different for each option for one- and two side colouring:

- Single storage tank

- Two pumps delivering starch to size press

- Receiver tank before the pump for top coloured side

- Single flat vibrating screen filtrating recirculated starch from top coloured side and from top side coating spray shower overflow

Only for two-side colouring:

- Single storage tank

- Single pump delivering starch to size press

- Single flat vibrating screen filtrating starch backflow from both coating spray showers and from overflow

Concept

- Twin-shell storage tank 1 to 5 m with slow-running agitator integrated in support frame

- Screw pumps controlled by means of frequency converters

- Receiver tank integrated in support frame

- Flat vibrating screen integrated in support frame

- Starch filter on pump delivery side integrated in support frame

- Automatic fittings enabling fully automated station operation mode

- For required volumes larger than 3 m the tank is erected separately but the pumping and filtering system is a unit assembled into the support frame

- Electric switchboard

- Complete inner cabling and piping

The stations are always delivered in compact units to be connected to media sources and starch delivery and backflow pipelines.

The tank twin-shell is used to keep starch on a constant temperature set by the control system. Depending on the conditions, the shell is either water cooled or steam heated.

The workstation is controlled together with the size press. No control system is delivered with the workstation.

The machinery design and safety comply with the EU and EAC industrial standards.

Station parameters

For PM capacity of:

1 – 30 tph

System:

– Single pump (starch coating the same for both paper sides)

– 2 pumps (starch coating with colour or surface sizing agent only for one paper side)

Storage tank volume:

3 – 5 m

Tank equipment:

Slow-running agitator, twin shell for heating/cooling, measuring & control elements (level sensors, temperature sensors)

Material:

stainless acid-proof steel

Pump performance:

1 to 45 m /hr max., controlled by means of frequency converter depending on the PM performance

Recycling ratio:

1:3 – 1:5

Starch filtration:

before size press inlet, filter 250 µm, backflow filtered through coarse filter (paper scraps) and flat vibrating screen VP 250 – 500 µm as per the request

Station design:

For volume 3 m tank installed in support frame together 3 with dosing pumps; for volume > 3 m tank erected outside frame

The machinery design and safety comply with the EU and EAC industrial standards.

Energy demand

Rated input: 4 to 50 kW / 3x 400 VAC / 50/60 Hz

Instrument air: min. 5 bar, dew point -20 C

Fresh water: min. 3 bar, no mechanical impurities

-

Category

Cultural / Industrial Length

4 feetWidth

6 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]