Size Press

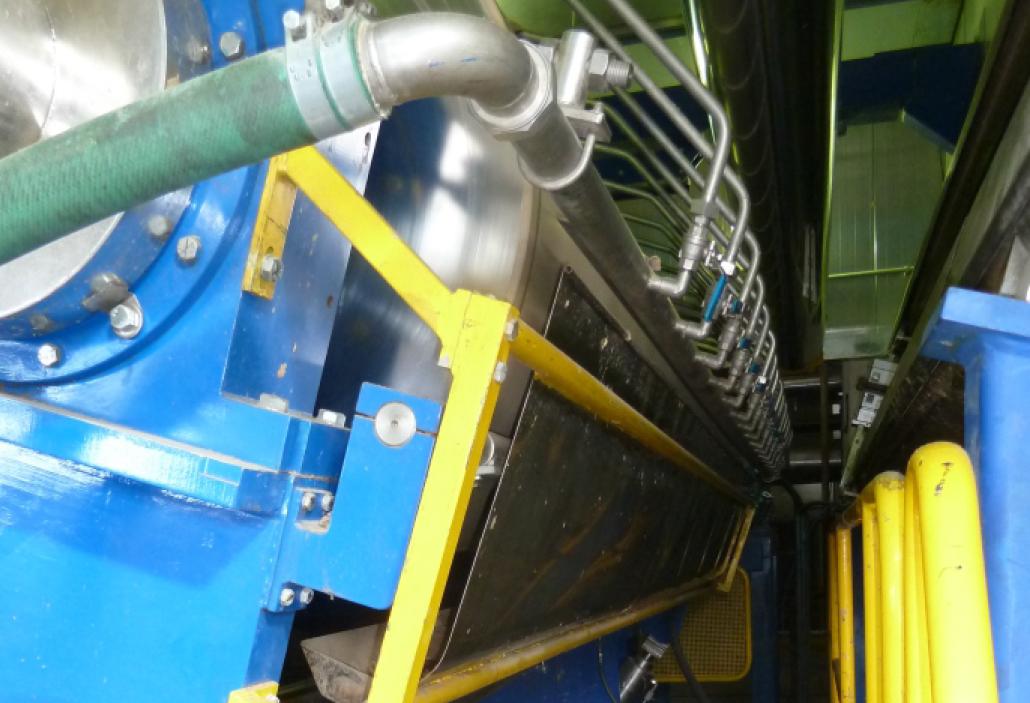

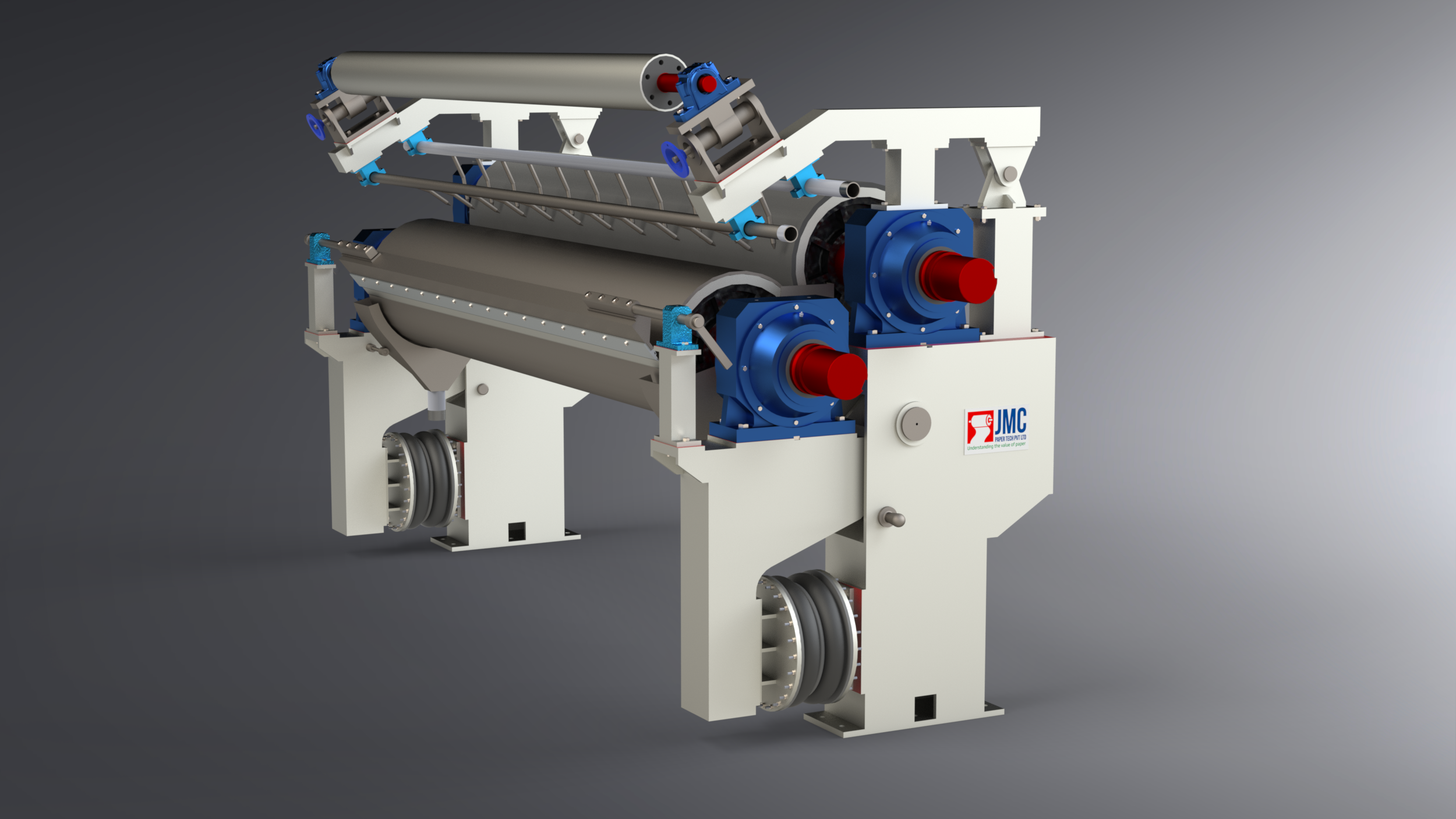

Size Press is located in the machine behind the pre-drying part, is made as two-roll press with hydrarulic or pneumatic loading. Press rolls are settled horizontally and its movable roll (first roll in paper run direction) is arranged under the stationary roll.

Design

The rolls are dynamically balanced on demanded speed and can be covered with different coats (rubber, ceramics) depending on produced kind of paper and type of sizing agent. The sizing agent proceeds through distribution pipes between the rolls and retained by outside dams.

Volume of sizing slurry can be controlled through set of valves, which are regulated either manually or electric-pneumatically.

Paper web proceeds through the bath to be sized. Sizing agent surplus is led through system of waste troughs and pipes back to the working station. Roll surface coming not in contact with paper web and front parts of the rolls are cleaned by set of side and front doctors.

Paper can be sized according to demand on both or one side only in the sizing press. Paper web run through the size press is modified by use of shifting unit of inlet guide roll. After sizing the paper is led through guide roll under pressing part onto spreader roll, which spreads the paper web across its width before inlet to the after-drying part (usually on a pair of drying cylinders with chrome-plated

surface).

System of threading ropes is part of the size press and its design enables save feeding of the paper web from previous to the following drying section of the paper machine.

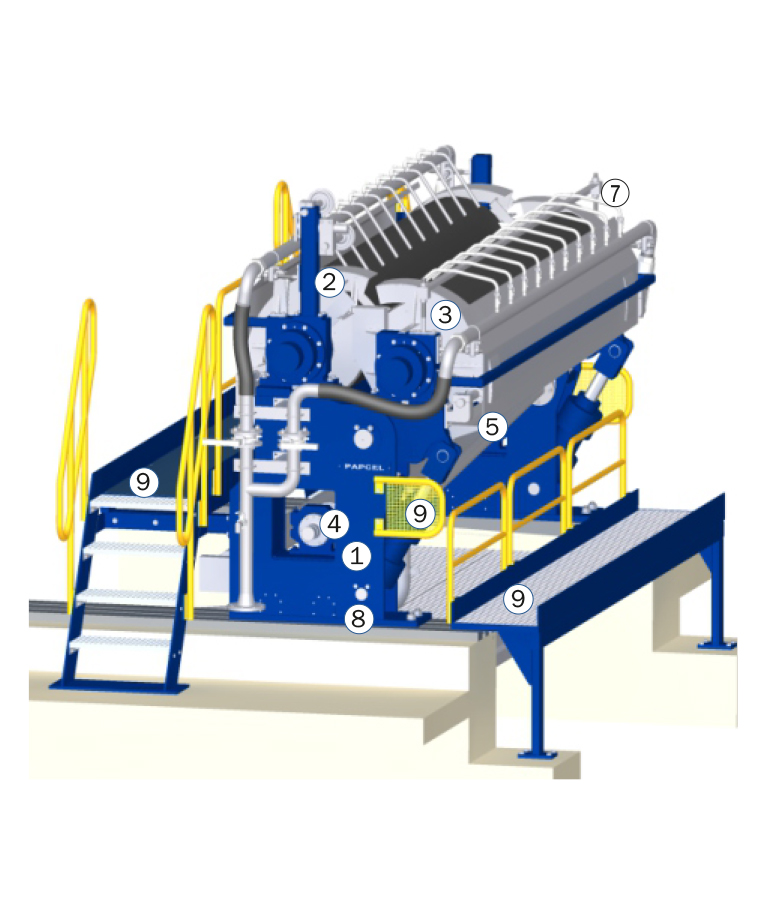

Main parts

- Bearing structure consisting of particular stands fixed by bolts and locks together (1)

- Stationary press roll with bearing (2)

- Movable press roll with bearing (3)

- Shifting equipment

- Paper guide rolls (4)

- Side and front doctors (5)

- Spreader roll with drive (6)

- Size agent inlet (7)

- Size agent outlet (8)

- Hydraulic circuit; control console; pneumatic circuit

- Safety covers and foot bridges (9)

Material

- Bearing structure and the rolls are made of common carbon steel

- Size agent inlet and outlet parts are of stainless steel

Accessories

- Rope threading

- Size press drive (mechanic and electric part including control)

- System of sizing agent preparation

Scope of delivery

- Complete machine according to description of main parts

- Accessories according to customer’s inquiry

Paper surface treatment

- Surface sizing – to get an effective quality improvement of produced paper and reduce sizing agent consumption due to their better retention (compared to sizing in substance)

- Surface treatment by special agents – to reach hydrophobic, greaseproof properties etc.

- Surface dyeing – costs saving compared to dyeing in substance, reaching of speacial color effects and reducing of

waste water pollution - Thin layer of special coats – thermoplastics, pigments, clays etc.

| Technical parameters | ||

|---|---|---|

| Design of size press | horizontal with inclined line of centres | |

| Configuration | two-roll | |

| Max. design speed | m/min | 850 |

| Press roll diameter | mm | 600 - 1,350 |

| Max. operating width | mm | 7,500 |

| Linear pressure | kN/m | max. 80 |

| Sizing | g/m2 | max. 4 on each side at dryness 6 - 10 % b.d. |

| Control mode | manual / automatic | |

On customer’s demand we supply machines with different parameters.

-

Category

Paper Machine Section

IndustrialPaper/CulturalPaper/SpecialtyPaper

Company Presentation

[elementor-template id="3268"]