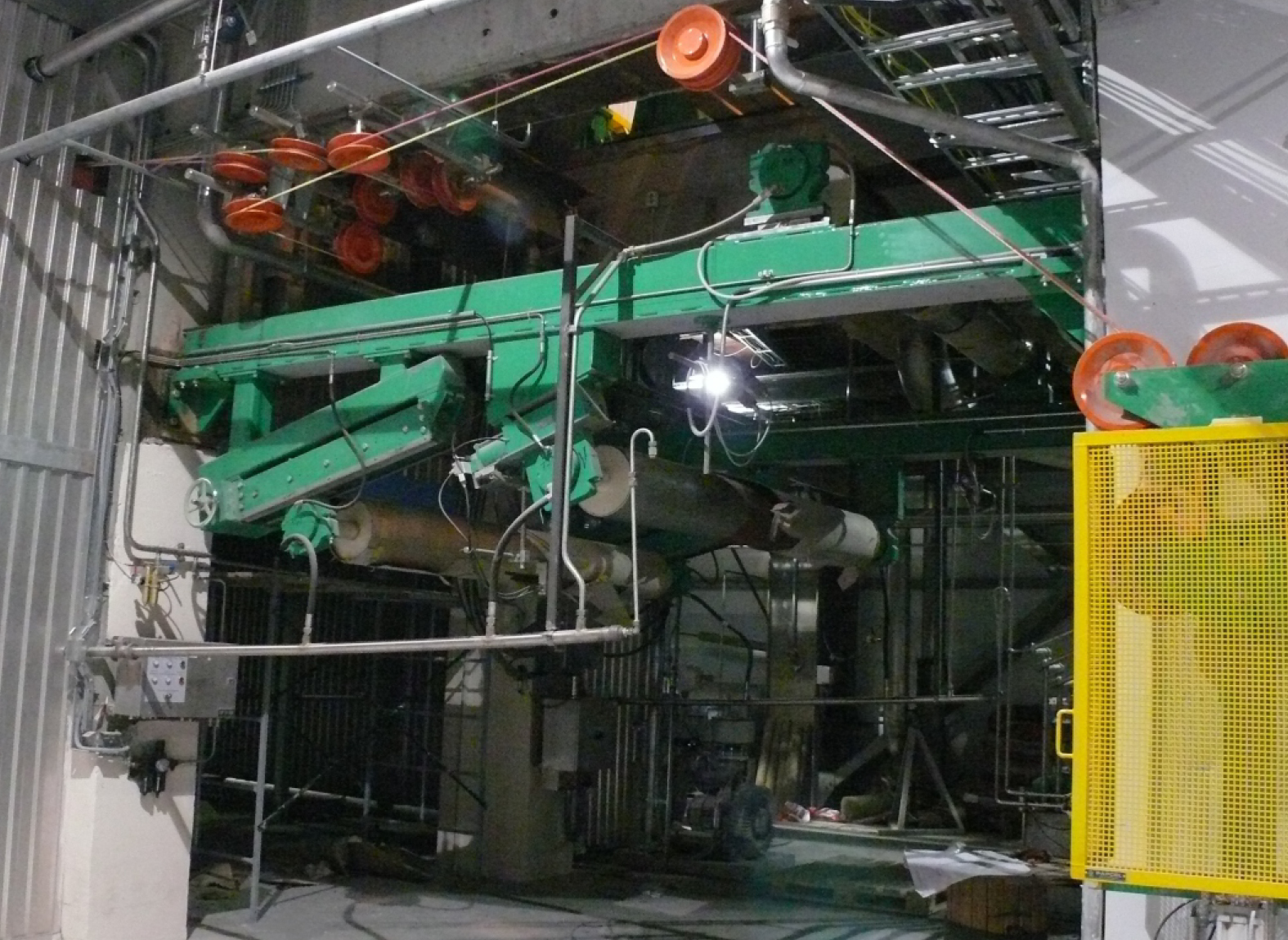

Rope Threading System

Rope threading system is used for utomatic paper web threading through the threading ropes from the press part via drying section onto the reel of the paper machine.

Design

It consists of a set of pulleys, rope stretchers and if necessary a rope drive. Auxilliary chutes and air pipes with nozzles can be used as other equipment to be placed in transfer points. A two-rope system is applied normally, but for heavier paper grades a three-rope system can be used. Because of different speeds in different parts of PM, the rope threading system is divided into several sections. Into the sections, where the paper web transfer is more complicated, the tail shooter with the cutter and with air or vacuum transporter is installed.

Rope pulleys

Pulleys dimensions (diameter, width, groove depth) depend on the machine speed and the basis weight.

Leading pulleys

The pulleys are used to form rope threading wedges (lower depth of a groove) in transfer points.

Guiding pulleys

The pulleys are used for guiding threading ropes in the machine (higher depth of a groove) and are manufactured in a single or double modification.

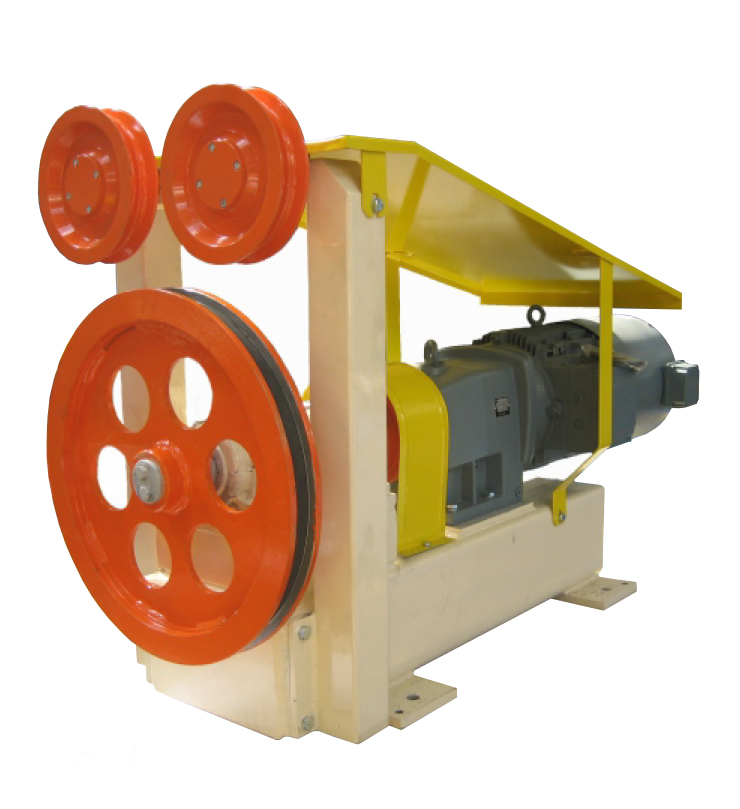

Ropes drive is used when the threading ropes do not pass through the drying cylinders or when the web contact is not sufficient for the rope dragging which might cause slips. The speed of the electric motor is controlled by a frequency converter and is derived from the speed of a closest suitable roll. The drive is provided with a safety cover.

Main parts

- Pneumatic rope stretching

- Set of pulleys with holders

Material

- Standard design is common steel, eventually stainless steel according to customer’s request

Accessories

- Threading rope drive

- Tail cutter

- Tail shooter

- Air conveyor

Scope of delivery

- Complete machine according to the main parts description

- Accessories optional, upon customer’s request

Rope stretching system is designed for stretching the threading ropes individually. Its size depends on an overall rope length of a threading circle.

Vertical mechanical rope stretching is done by a system of weights. The system allows rope stretching by a doubled stroke (L=2 x STROKE). Offered only upon customer’s request.

Rope stretching system is done by pneumatic cylinders controlled by a pneumatic control board. The system allows rope stretching by a quadruple stroke of pneumatic cylinders (L = 4 x STROKE). Maximum rope stretching stroke (pulleys in end positions) is signalled by magnetic position sensors.

Rope stretching system is done by pneumatic cylinders controlled by a pneumatic control board. The system allows rope stretching by a quadruple stroke of pneumatic cylinders (L = 4 x STROKE). Maximum rope stretching stroke (pulleys in end positions) is signalled by magnetic position sensors.

Advantages of the pneumatic rope stretching

Continuous and simple adjustment of the required stroke of the threading ropes and a possibility of a stroke release when the paper is threaded. A fully automatic equipment.

Machine design and work safety are in compliance with the EU and EAC standards.

| Technical parameters - vertical stretching | ||

|---|---|---|

| Stroke (m) | Stretching height (m) | |

| 0.60 | 1.25 | |

| 0.75 | 1.42 | |

| 0.95 | 1.60 | |

| 1.10 | 1.75 | |

| 1.25 | 1.90 | |

| Technical parameters - horizontal stretching | ||

|---|---|---|

| Stroke (m) | Stretching height (m) | |

| 0.50 | 1.88 | |

| 0.75 | 2.38 | |

| 0.90 | 2.68 | |