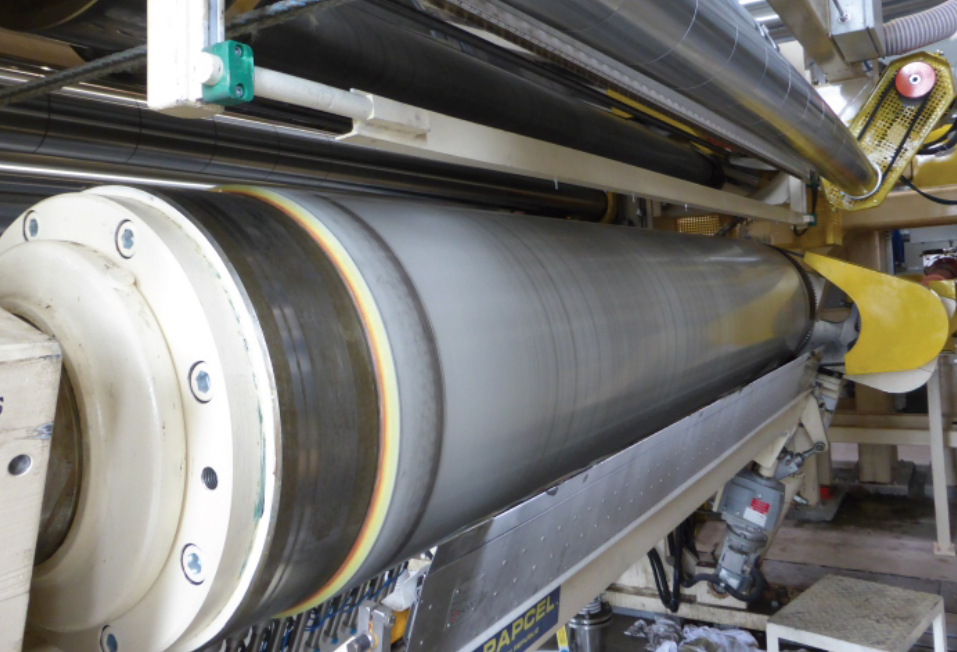

Rolls

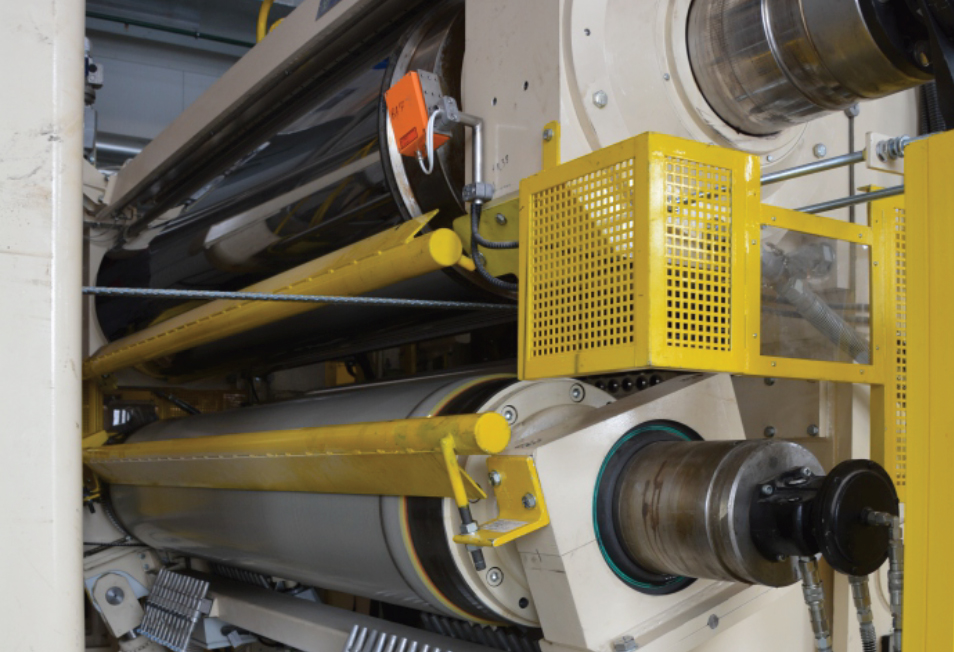

Rolls are the basic functional element of the paper machine. Design of each roll depends on its location in PM and its usage purpose. The rolls are standardly dynamically balanced for the required designed speed. For long slim rolls, we use a method of dynamic roll balancing in more levels.

Some rolls are operating as pressure vessels (with internal overpressure), are designed and tested in compliance with EU standards. If required, the rolls are delivered with corresponding certificates.

List of the rolls produced for the paper industry

- Guide rolls for wire, press and drying wire and paper (made of steel, grinded, with a rubber cover, copper-plated, chrome- plated, plasma-sprayed)

- Deflocculation rolls for headboxes

- Segment rolls for rewinders (made of aluminium alloy)

- Driving rolls with a rubber cover for wire parts

- Forming rolls for a Crescent former

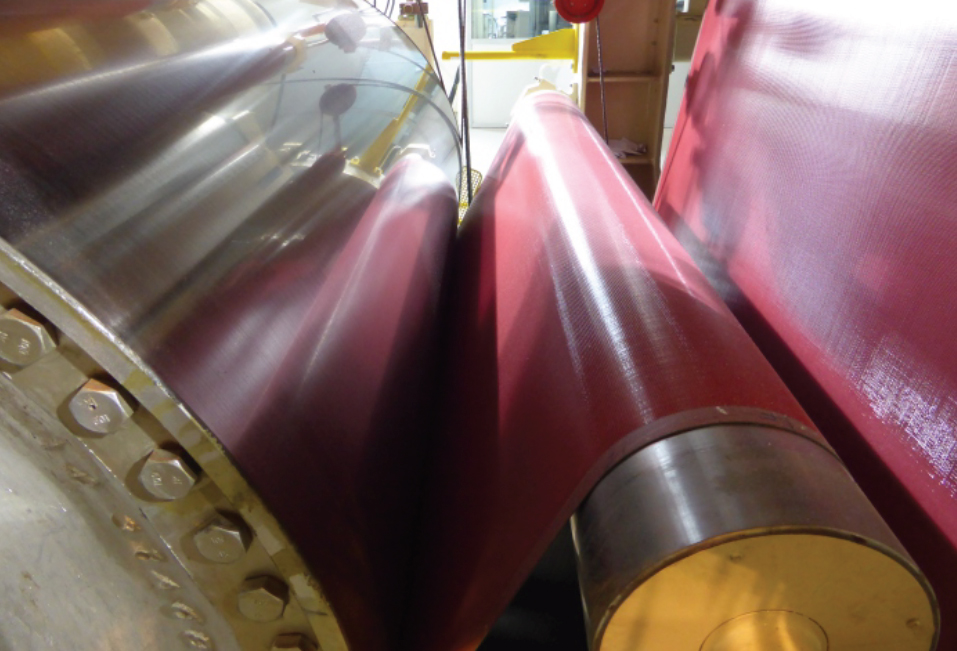

- Press rolls (incl. rolls for JUMBO presses) with blankets and internal cooling system

- Drying cylinders

- Made of cast iron or welded

- Chrome plating included, or with special coatings

- Fix or free rope pulleys included (possibly with rope grooving)

- Size press rolls-incl. covers in accordance with the sizing agent and pressure

- Yankee rolls

- Carrying rolls of a rewinder, plasma spraying included

- Carrying rolls of a reel – made of cast iron or welded carbon or stainless steel)

- Reel spools – incl. covers (polyurethane, rubber)

- Suction rolls, pressure

- Transfer rolls

- Spreading rolls – paper, felt

Rolls types

- With hot-pressed cast ends and with pressed-on steel pins

- With hot-pressed steel pins or pins fixed through freezing

- With bolted ends

Design

The company produces rolls, cylinders and cylindrical bodies in all known design modifications, such as;

- Massive rolls

- Rolls made of weldless thin-walled and thick-walled tubes

- Rolls made of grey cast iron

- Roll-bended

- Cylindrically grinded or crowned

Material

- Depending on customer’s request

- According to the load

Machine design and work safety are in compliance with EU and EAC standards.

Rolls can be delivered with following coatings and covers:

- Rubber or polyurethane cover, teflon cover, copper plating, ceramic cover, hard chrome plating or high-grade steel coating (stainless steel, type 13 % Cr, chrome- nickel steel, chrome-nickel-molybdenum steel, tungsten-carbide etc.) according to special requirements

- We provide rolls with particular coating and covers as blind-bored, grooved or with combined surfaces

Special roll surfaces can be provided also through subdeliveries by reputable and specialized roll manufacturers within the scope of delivery and based upon previous agreement with the customer.

Servicing

For all mentioned rolls (made or by PAPCEL or other manufacturers), we provide repairs, overhauls and replacements of roll pins and also coating of necks, grinding of roll surfaces and also new covers. The service is offered completely, i.e. from dismantling of the roll through its repair. For all rolls, we produce and deliver also the bedding for oil and grease lubrication.

Rolls are delivered for all available paper grades for paper machines with wire table up to 7.500 mm.