Pumps are designed to transport papermaking stock at consistencies up to 6 % and at pH values of 6.0 to 8.0 and to pump water, polluted liquids and sludges. Depending on process conditions, centrifugal pumps, fan pumps, screw pumps and other pump sorts are delivered. Fan pumps before paper machine headboxes are equipped with special low pulsating impellers.

Pump choice

Pump parameters and types are specified based on mechanical projects. Choosing a single pump the following must be specified:

- Pump positioning in the line

- Pump throughput (min., max.)

- Pump delivery height or delivery pressure

- Stock specification (pumped stock sorts, consistency, pollution)

Design

A basic configuration of the delivered pump can be completed with a frame, an electric motor and a frequency converter.

The pumps are delivered with cord seals. On demand and/or depending on pumped medium a mechanical seal can be used.

Main parts

- Spiral case (1)

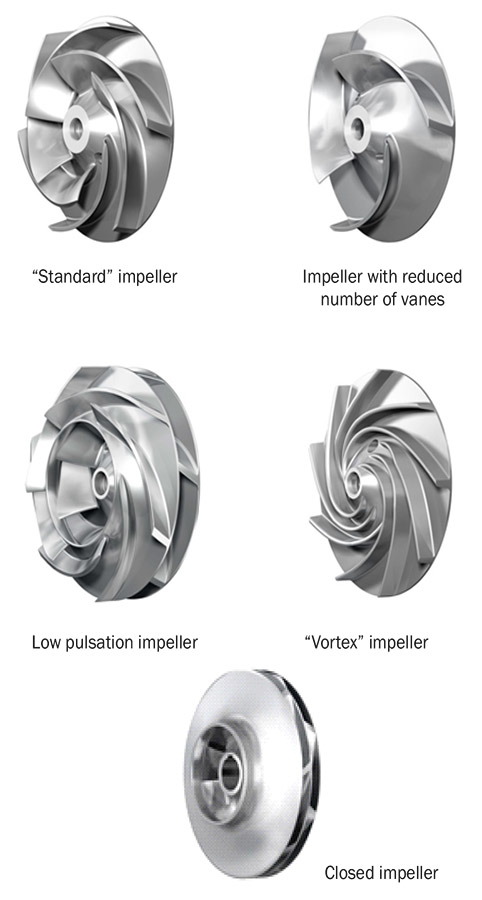

- Impeller (2)

- Shaft with bearings (3)

- Coupling with cover (4)

- Foundation frame (5)

- Electric motor (6)

Material

- All parts coming to contact with the stock are made of stainless steel

- Other parts are made of structural steel with protective coating

Accessories

- Pump delivery battery limits are input and output flanges without joining material and seals

- Frame without anchoring material

- Pre-bored coupling in the impeller shaft including cover

Machine design and work safety are in compliance with the EU standards and EAC.s