Periodical Reject Separator

Periodical reject separator PSN belongs to a family of secondary pressure pulpers. The machine is designed particularly for separation of undesired impurities, such as foils, plastic particles, leathers, rubber pieces, rags, woods, etc. from continuous pulpers of waste paper (vertical or horizontal). The separation itself is achieved directly during pulping. Periodical reject separator can run both in permanent or intermittent operation according to the volume processed and grade of impurities contained in the waste paper. While running, the remaining residues of hardly pulpable materials are being deflaked and washed with the goal to reduce fibre loss to a minimum.

Design

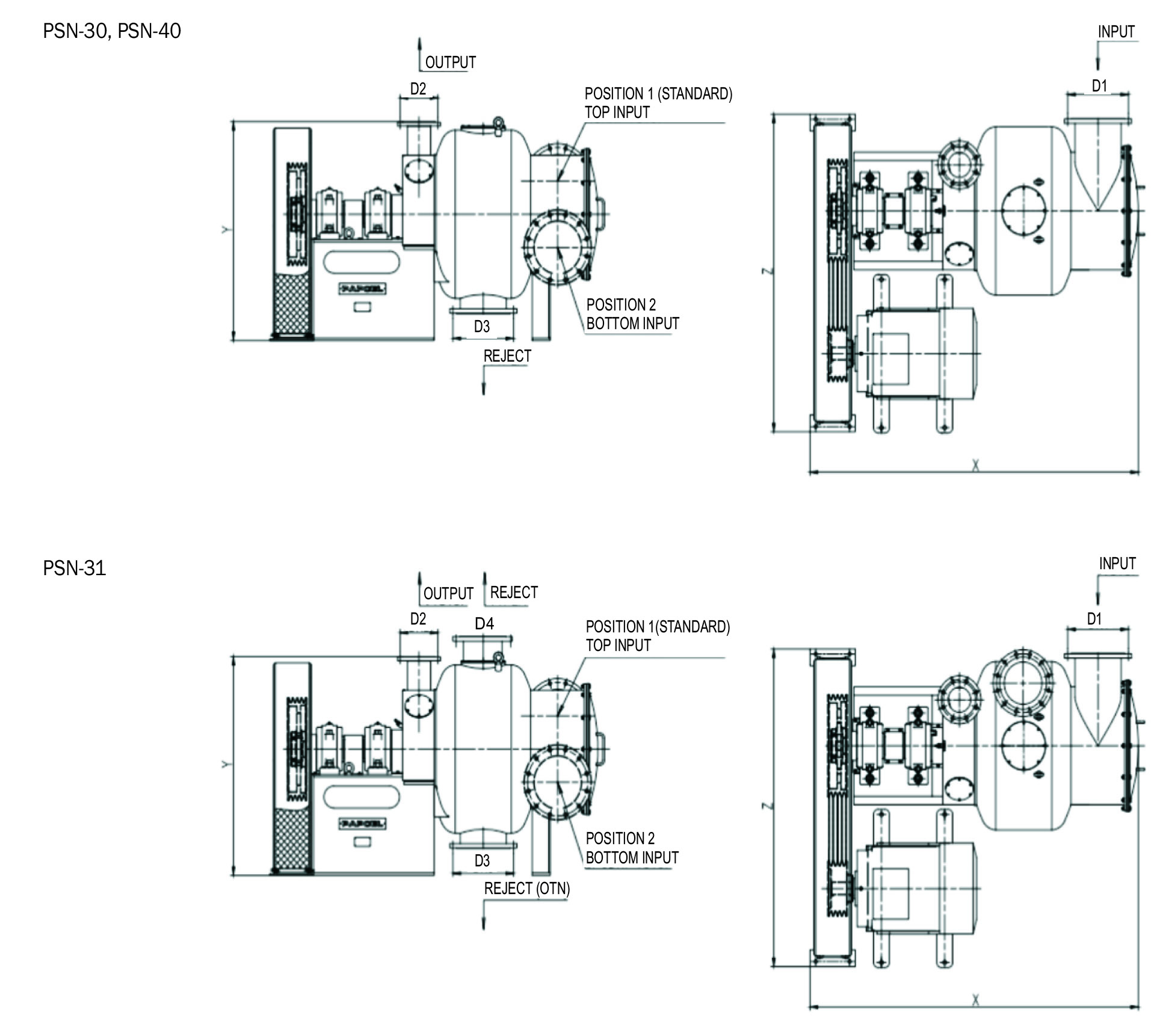

Machines are based on a similar design. Particular types differ:

- PSN-30 – design with bottom reject branch and flat screen ∅ 600 mm

- PSN-31 – design with top and bottom reject branch and flat screen ∅ 600 mm

- PSN-40 – design with bottom reject branch and cone-type screen ∅ 800 mm

Accessories

- Input, reject, output, heavy impurities separator slide valve (OTN)

- Pneumatically controlled flap valve of diluting water

- Pneumatic distribution block and control system

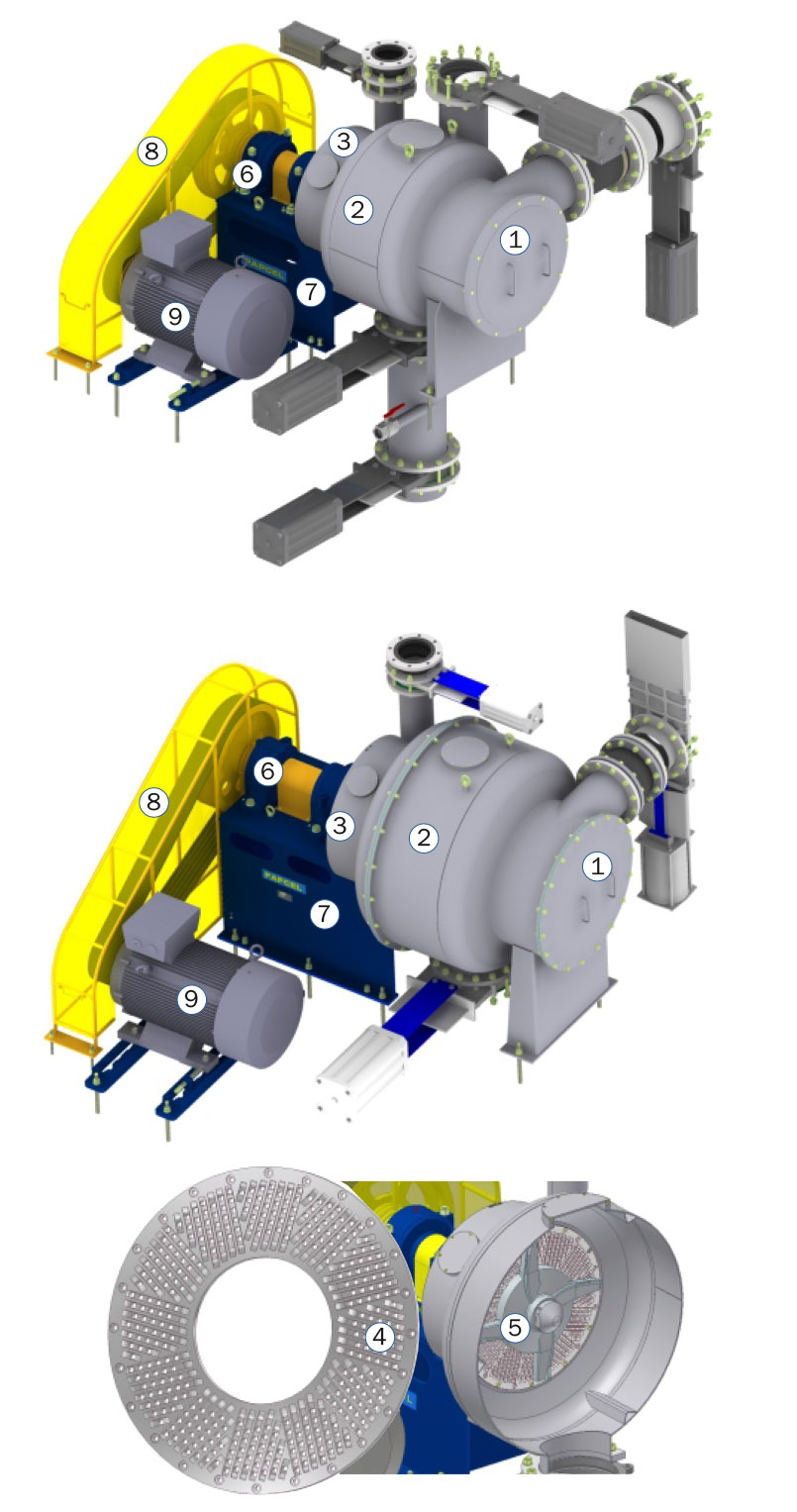

Main parts

- Input section of working chamber (1)

- Working chamber (2)

- Output chamber (3) with sealing plug

- Functional elements: sorting screen (4)

- Wiped by working and pumping rotor (5)

- Machinery bedding (6)

- Stand (7)

- V-belt drive with a cover (8)

- Electric motor (9)

Material

- All parts coming in contact with the stock (working chamber, output chamber) are made of stainless steel

- Other machine parts are made of structural steel with polyurethane coating

Machine design and work safety are in compliance with the EU standards and EAC.

| Technical parameters | ||||

|---|---|---|---|---|

| PSN-30 | PSN-31 | PSN-40 | ||

| Input | D1 | DN 300 | DN 300 | DN 300 |

| Output | D2 | DN 150 | DN 150 | DN 200 |

| Reject | D3 | DN 300 | DN 300 | DN 400 |

| Heavy impurities separator (OTN) | D4 | - | DN 250 | - |

| Diluting water diameter | D5 | DN 100 | DN 100 | DN 150 |

| Machinery length (X) | mm | 2 160 | 2 160 | 2 860 |

| Machinery height (Y) | mm | 1 300 | 1 300 | 1 880 |

| Machinery width (Z) | mm | 1 940 | 1 940 | 2 600 |

| Capacity*) | tpd | 40 - 70 | 40 - 70 | 80 - 150 |

| Electric motor output | kW | 55 | 55 | 90 |

| Machinery output incl. drive | kg | 1 900 | 1 900 | 3 300 |

-

Category

Cultural / Industrial Length

4 feetWidth

12 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]