Low Pressure Shower

Low-pressure shower NOT is used for wires and felts cleaning and conditioning. They influence considerably the felt and screen life time, PM productivity, the quality of paper produced and the energy consumption.

The showers are divided into following groups according to their function:

- Moisturizing

- Cleaning

- Lubricating

- Intensive

- Condensing

- Flooding

- Trimms showering

Design

Low-pressure showers are made of stainless steel in three standard versions:

- Shower with ø 60,3 mm

mounting pitch up to 3,500 mm - Shower with ø 76 mm

mounting pitch up to 5,500 mm - Shower with ø 108 mm

mounting pitch up to 7,000 mm

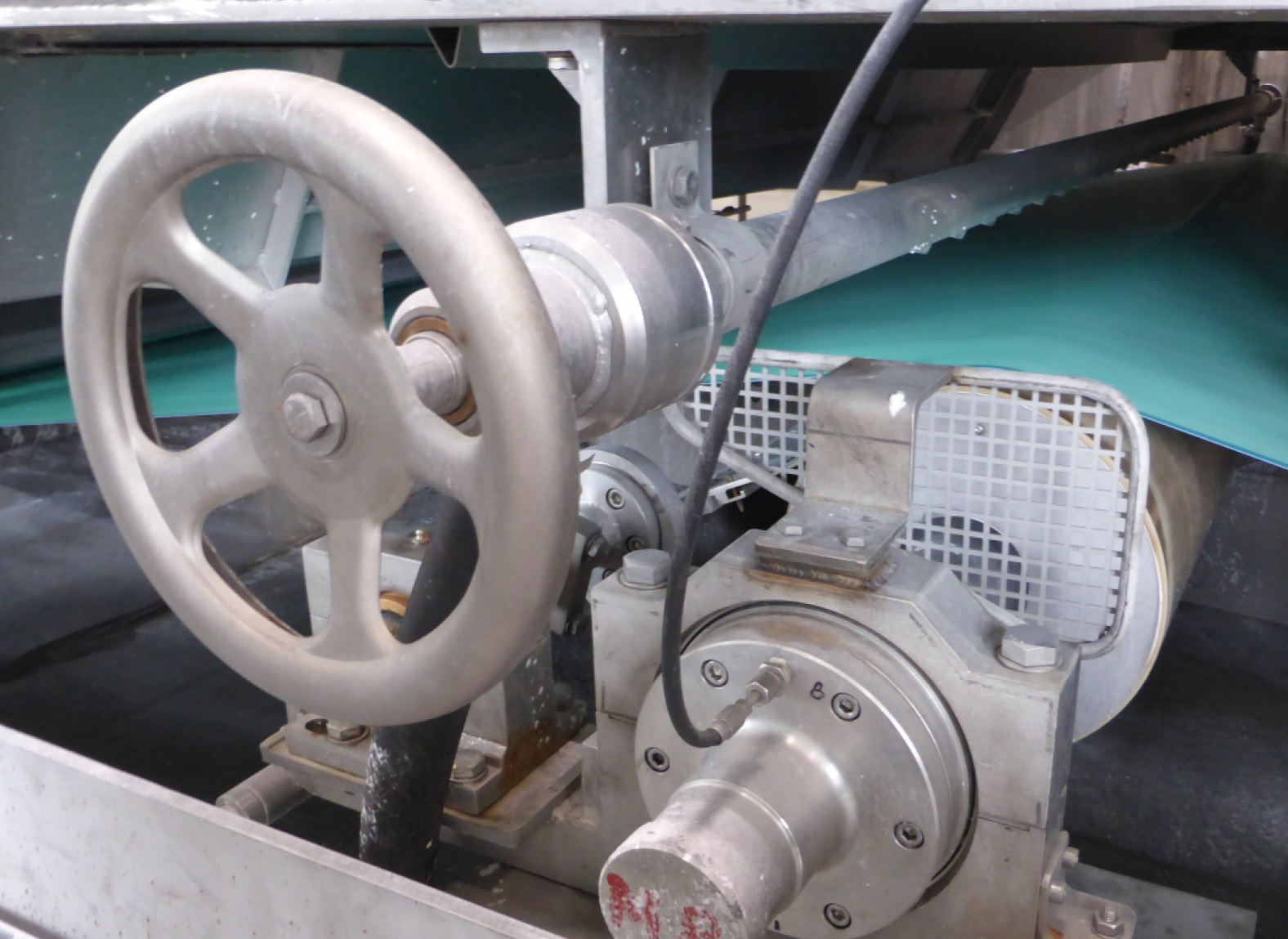

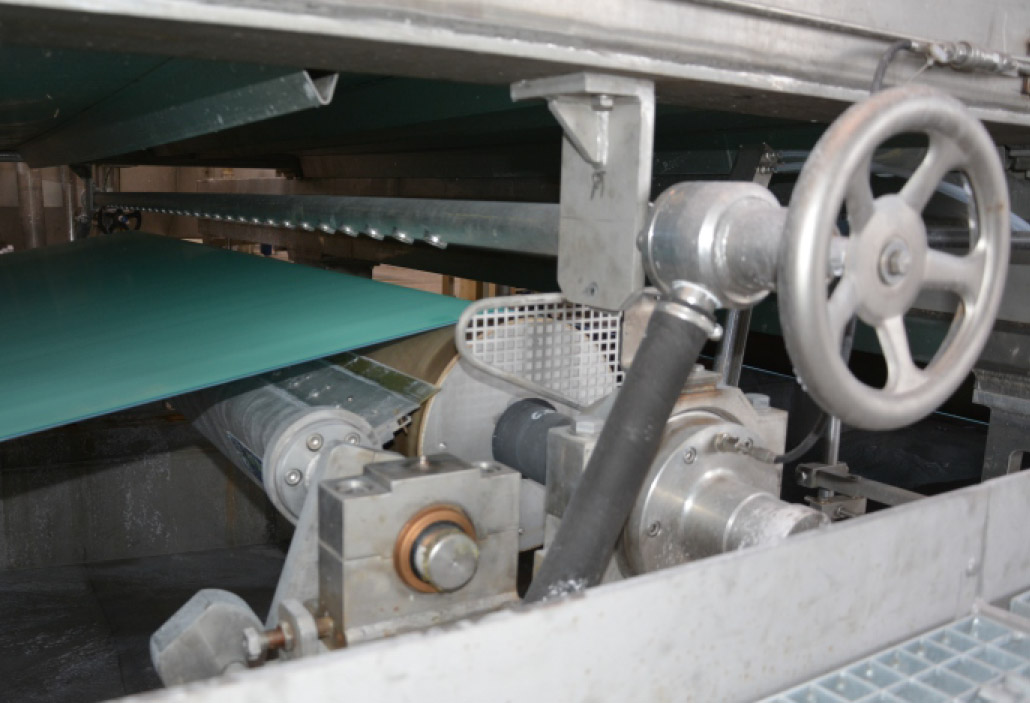

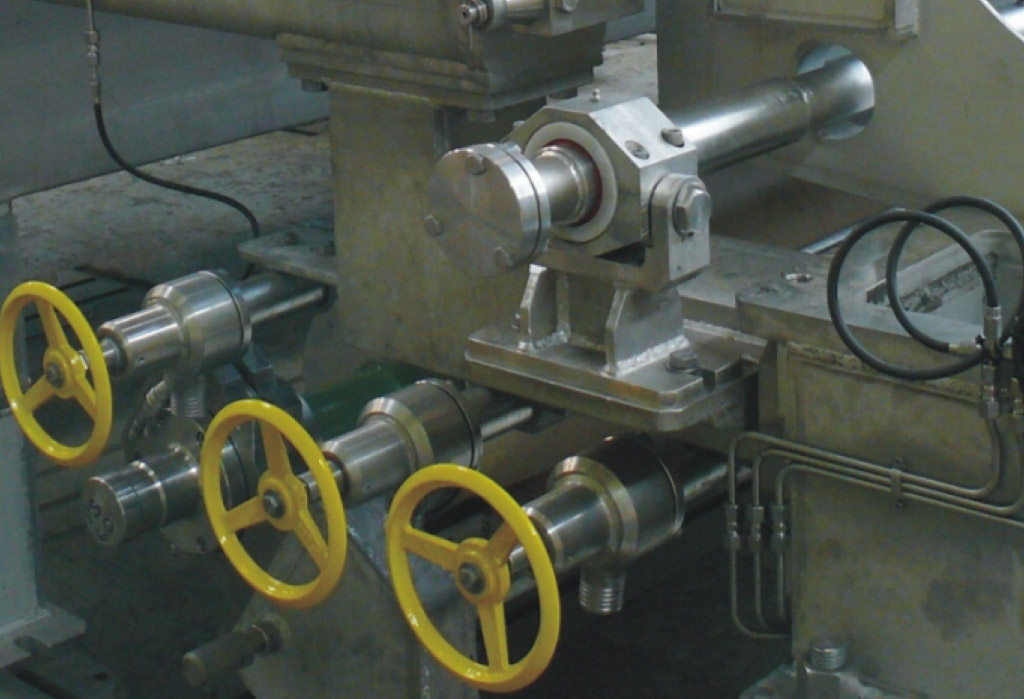

The showers dispose of attached nozzles with a flat jet in sizes 1 to 3 with a distance from the wire or felt of 80 – 120 mm. There is a cleaning brush inside of the shower that can be used for cleaning of nozzles and the inner surface of the shower from impurities. There is a head with a manual wheel on the operator side with the standard version that serves for a cleaning brush manipulation and valve opening of the waste water outlet.

There is a connection for a water supply on the other side. The pipes have nozzles fixed on them which are pressed or mounted into the pipe.

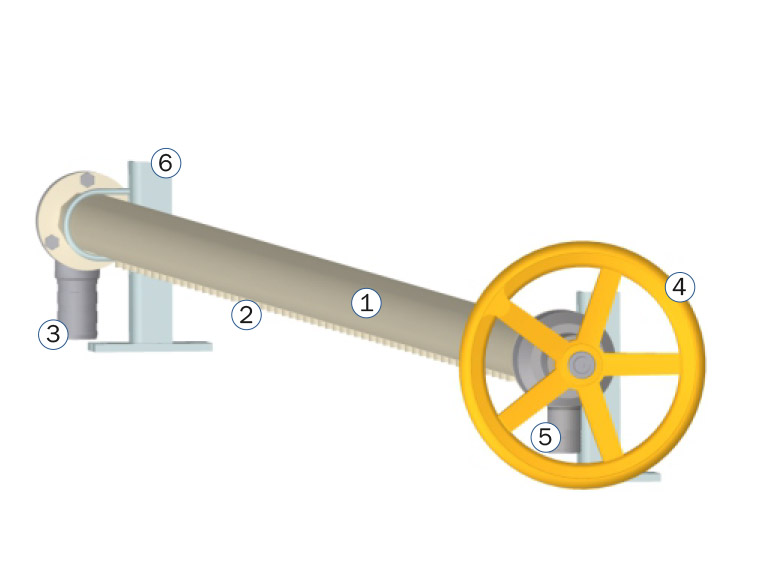

Main parts

- Shower with nozzles (1)

- Cleaning brush (2)

- Water supply (3)

- Cleaning brush wheel (4)

- Waste piping for sediments outlet (5)

- Stands for shower pipe fitting (6)

Material

- All parts are made of stainless steel

Accessories

- Inlet and outlet water hose

- Sealing fittings

- Stainless piping for water supply

Scope of delivery

- Complete equipment in accordance with the main parts description

- Accessories optionally

Clean water requirements

- Cleaned = max. water contamination 50 mg per litre

- Industrial = max. water contamination 9 – 12 mg SS per litre

- Max. SS size 20 μm

SS = suspended solids (insoluble in water)

Shower connection

PAPCEL provides complete shower connection individually or in groups to the machine water distribution system; assembly, startup and operator training included.

Low-pressure shower in the wire part of PM.

Machine construction and work safety are in compliance with EU and EAC standards.

| Technical parameters | ||||

|---|---|---|---|---|

| Flat jet | nozzle / | size | ||

| Water consumption per a nozzle | 1 | 2 | 3 | |

| 0.1 MPa | l/min | 0.7 | 1.5 | 4.4 |

| 0.2 MPa | l/min | 0.9 | 2.0 | 6.3 |

| 0.3 MPa | l/min | 1.2 | 2.6 | 7.7 |

| 0.4 MPa | l/min | 1.3 | 3.0 | 8.9 |

| 0.5 MPa | l/min | 1.5 | 3.3 | 9.9 |

| 0.6 MPa | l/min | 1.7 | 3.6 | 10.8 |

| 0.7 MPa | l/min | 1.8 | 3.9 | 11.8 |

| 0.8 MPa | l/min | 1.9 | 4.2 | 12.5 |

| 0.9 MPa | l/min | 2.0 | 4.5 | 13.2 |

| 1.0 MPa | l/min | 2.1 | 4.7 | 13.9 |

-

Category

Paper Machine Section

IndustrialPaper/CulturalPaper/SpecialtyPaper

Company Presentation

[elementor-template id="3268"]