High Pressure Oscillation Shower VOT

High-pressure oscillating showers VOT with an electromechanical oscillation are used for high-pressure cleaning of wires and felts in paper machines with clear water under a pressure of 1.0 to 5.0 MPa.

This cleaning procedure brings a positive influence on the felt and wire service life (keeping original properties of wires and felts for optimal PM operation), quality of produced paper and energy consumption.

Design

The high-pressure shower pipe is made of stainless steel in two standard modifications:

- Shower pipe ø 60,3 mm

mounting pitch up to 3,500 mm - Shower pipe ø 76 mm

mounting pitch up to 5,500 mm - Shower pipe ø 108 mm

mounting pitch up to 7,000 mm

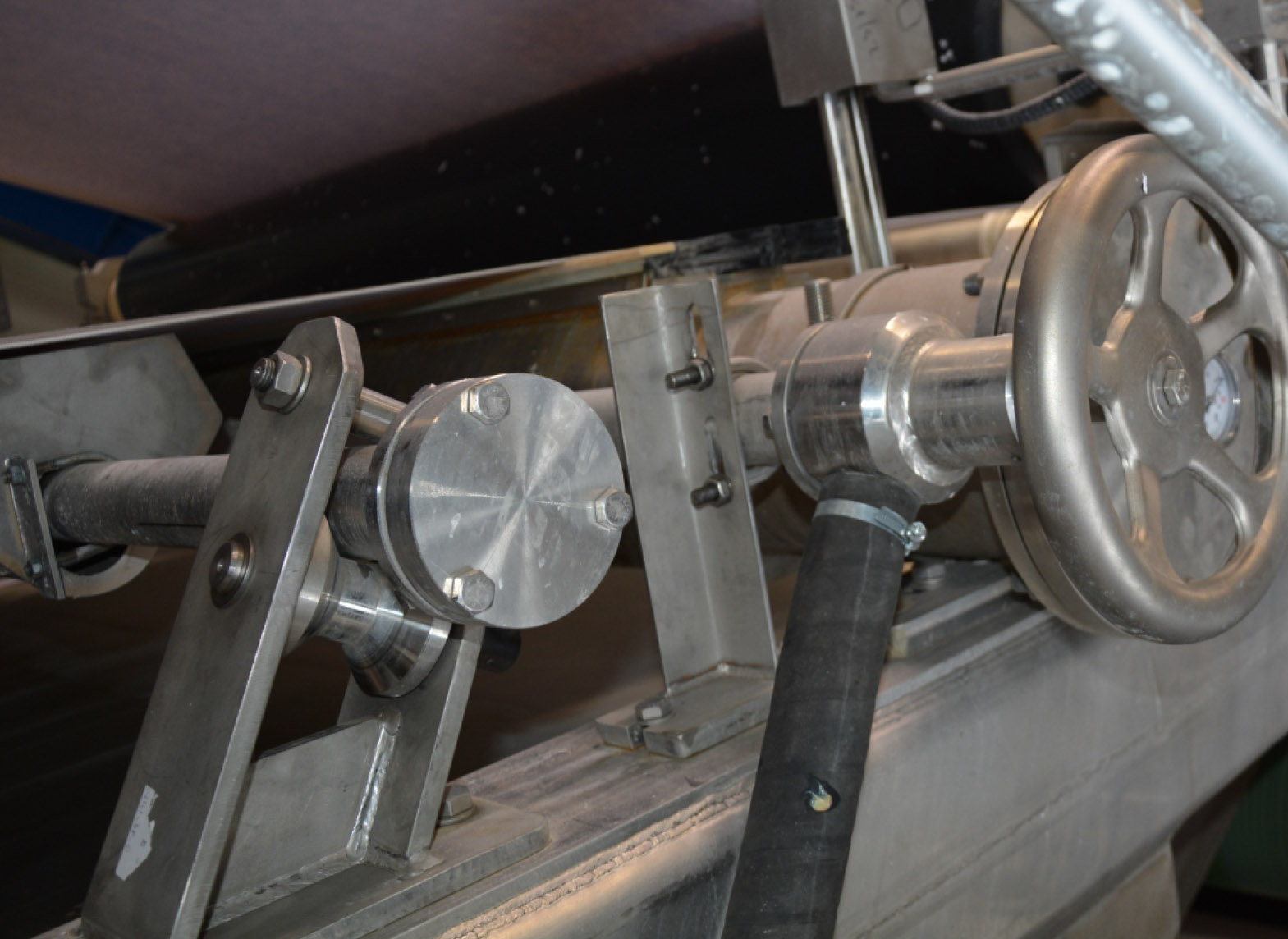

High pressure shower pipes are provided with nozzles with a needle jet of 0.84 to 1.75 mm diameter. To provide optimal form of cleaning, their max. distance from the wire or the felt should not exceed 100 mm. Max. pitch of nozzles in connection with the oscillator stroke should not exceed 125 mm. The standard modification is equipped on its control side with a blind flange to enable required cleaning of the inside space and nozzles. A connection for a high-pressure hose is installed on the drive side. Optionally, the shower pipes can be equipped also with a cleaning brush for cleaning of the inside space and nozzles.

Oscillation control

A special control mechanism allows any desired adjustment of the shower pipe stroke within the range of the oscillator stroke (max. 250 mm). Adjustment of the feed speed can be done manually (through PM speed values that are entered through keyboard on PM control board) or automatically (the feed rate is directly derived from the PM drive).

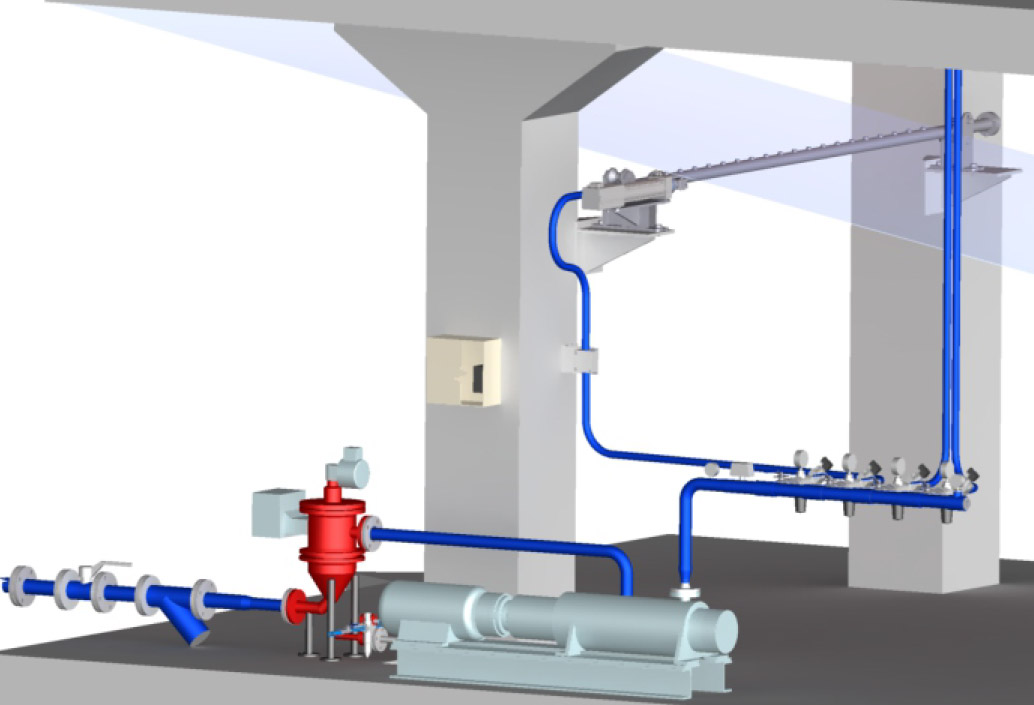

The control mechanism enables connections of more oscillating shower pipes to one control panel. This control panel can control also a pump operation, filters in a pump suction and delivery lines and water supply to particular oscillating shower pipes. It is also comprised of a blocking system and links to particular system groups together with a blockage of PM drive.

Main parts

- Electromechanical oscillator with a drive (1)

- Oscillator holder and shower pipe guiding (2)

- Pulleys (3)

- Shower pipe with nozzles (4)

- Shower pipe conduit holder (5)

- Inlet hose with cube (6)

Material

- Oscillator outer parts, shower pipe and nozzles are made of stainless stEel

Scope of delivery

- Complete equipment according to the main parts description

- Accessories optionally

Accessories

- Oscillation control

- High-pressure pump

- Liquid filter before pump

- High-pressure filter

- Shutting and control fittings (electromagnetic or pneumatic)

- High-pressure hoses

- Stainless steel piping for high-pressure water

Requirement for water cleanness

- Max. content of impurities 20 mg NL/l water

- NL = insoluble substances

It is necessary to install a corresponding filter in the HP pump suction line.

Electromechanical oscillation principle in a relation to the machine speed

The shower pipe oscillation runs discontinuously as required. The shower pipe motion (oscillation) is carried out by an electromechanical oscillator. The basic part of the electromechanical oscillator is a motion screw transmitting a rotary motion into a linear one. In the end positions, the motion reverses, which brings linear motion of the oscillator piston rod backwards.

Speed of this shifting can be calculated as follows:

V = (V x ø ) / l osc macine nozzle wire (felt)

This brings shifting (stroke) by a nozzle diameter per a wire (felt) rotation which causes very intensive washing without leaving any uncleaned spots. The oscillator introduces a compact encased device preventing water penetration into the working space. Its outer parts are made of stainless steel. The retractable piston rod of the oscillator is protected against coarse impurities by a collar. On both sides the shower pipe is resting on rollers bedded in self-lubricating bushing of stands. One of theses stands serves also as an oscillator holder. Fitting dimensions of both stands are identical allowing installation of the oscillator both on the drive side and on the control side. The oscillator is connected with the shower pipe by a sleeve.

Technical data of oscillation

- Oscillator stroke – 250 mm

- Shifting speed – according to PM speed and wire or felt length

- Drive – 250 W, 380 V, 50 Hz

Pneumatic oscillation principle in relation to the machine speed

The basic part of the oscillation system is a pneumatic cylinder which enables lifting of the rod from 1 to 250 mm. To make cleaning more efficient a control valve is used to control the speed of the pneumatic cylinder.

| Technical parameters | |||||

|---|---|---|---|---|---|

| Nozzle | with needle | jet | (diameter in mm) | ||

| Water consumption / pressure | 0.8 | 1.0 | 1.4 | 1.75 | |

| 1.0 MPa | l/min | 1.19 | 1.70 | 2.96 | 4.96 |

| 1.5 MPa | l/min | 1.44 | 2.07 | 3.60 | 6.03 |

| 2.0 MPa | l/min | 1.65 | 2.39 | 4.14 | 6.94 |

| 2.5 MPa | l/min | 1.85 | 2.66 | 4.60 | 7.74 |

| 3.0 MPa | l/min | 2.01 | 2.89 | 5.02 | 8.41 |

| 4.0 MPa | l/min | 1.70 | 2.25 | 3.25 | 5.72 |

| 5.0 MPa | l/min | 2.50 | 3.60 | 6.35 | 10.40 |

Water consumption per a nozzle (l/min)

-

Category

Paper Machine Section

IndustrialPaper/CulturalPaper/SpecialtyPaper

Company Presentation

[elementor-template id="3268"]