Film Press

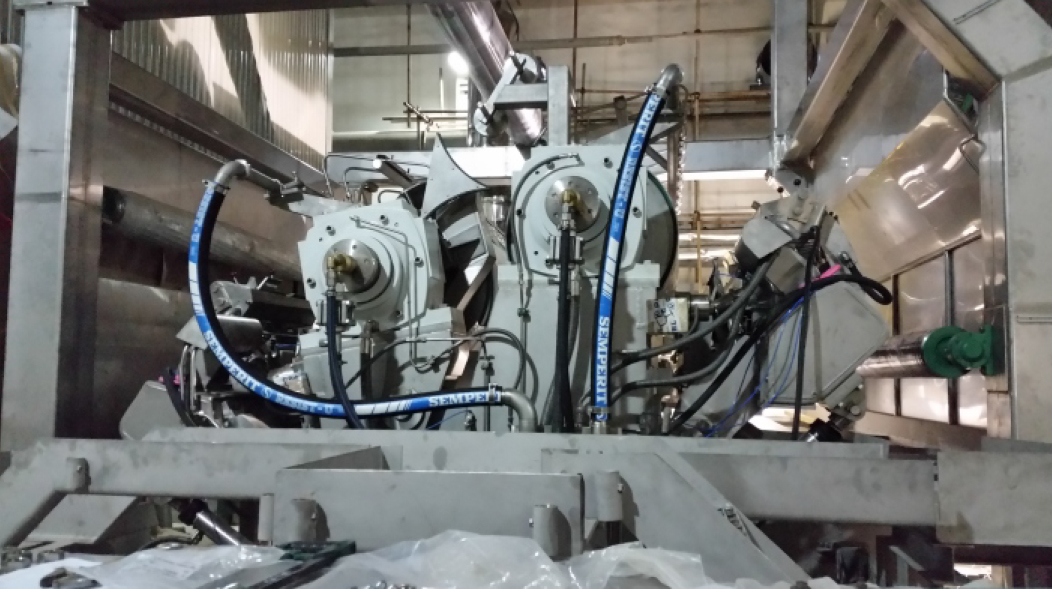

Film press (application press) is put directly in paper machine after pre-drying section. It is made as two roll press with inclined presses axis. The pressure is deduced through lever mechanism with hydraulic or pneumatic pressure.

The pressure is controlled according to technological demands from 0 kN/m to maximal load 40 kN/m.

Coated medium (for instance mixture of starch, sizing agent, AKD, pigment etc.) is transported to dosing chamber and proceeds to the calibrating space. Thickness of applied media on paper surface is here calibrated by use of profiled bars.

Design

Press rolls are designed on maximal load and dynamically balanced on demanded speed and covered with special coats depending on produced paper kind. Bearing structure is made of common or stainless steel according to customer’s inquiry. Profiled bars have diameter 10 – 38 mm and are made from stainless steel with chrome plated cover.

Paper surface treatment

- Surface sizing – to get an effective quality improvement of produced paper and reduce sizing agents consumption due to their better retention (compared to sizing in substance)

- Surface treatment by use of special agents – to reach hydrophobic, greaseproof properties etc.

- Surface dyeing – costs saving compared to dyeing in substance, reaching of special color effects and reducing of waste water pollution

- Thin layer of special coats

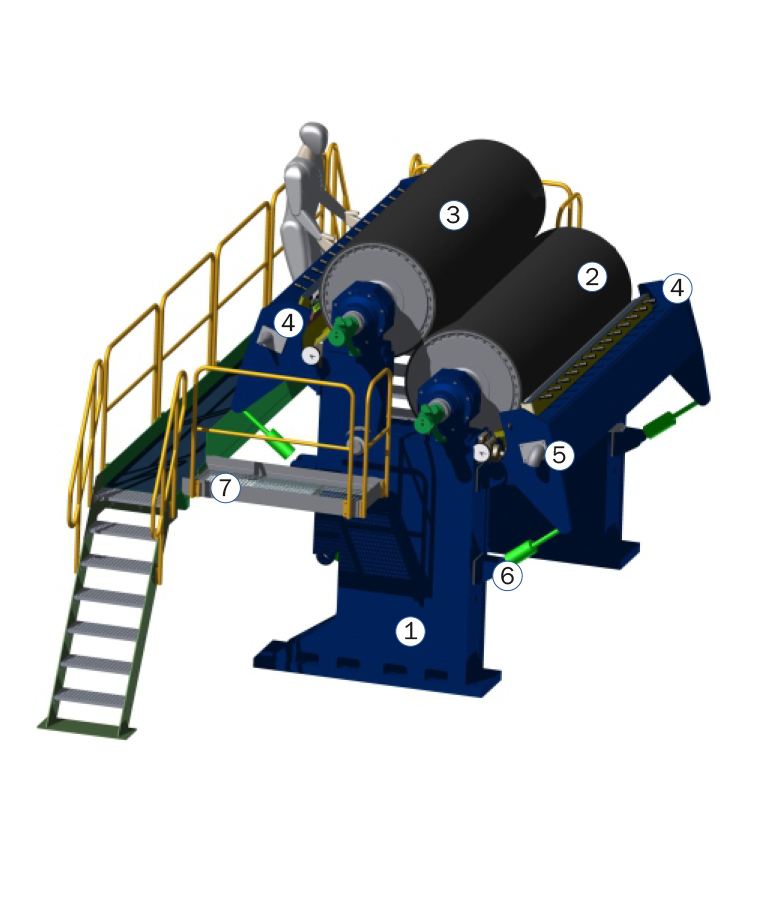

Main parts

- Bearing structure (1)

- Stationary press roll (2)

- movable press roll (3)

- Coating head with profiled bar (4)

- Paper guide roll

- Sizing agent supply (5)

- Sizing agent outlet

- Hydraulic and pneumatic system (6)

- Safety guards and machine foot bridges (7)

Accessories

- Press rolls and profiled bars drive

- Control system incl. control console

- Paper rope threading

- System of sizing agent preparation consisting of:

- Working station

- Starch kitchen

- Cross knife before film press

- Air blowing (air turn) after film press

- Infra – drying

- Retaining tank under film press

We offer complete overhauling and rebuilding of film presses and their parts besides productions of new ones.

| Technical parameters | ||

|---|---|---|

| Diameter of stationary press roll | mm | 1,010 (805) *) |

| Diameter of movable press roll | mm | 1,005 (800) *) |

| Maximal roll width | mm | 7,500 |

| Maximal design speed | m/min | 1,200 |

| Maximal linear load | kN/m | 40 |

| Sizing | up to 4 g at dryness 10 - 15 % | |

* valid for rolls up to 3 m width

-

Category

Paper Machine Section

IndustrialPaper/CulturalPaper/SpecialtyPaper

Company Presentation

[elementor-template id="3268"]