Equipment For Manufacture Storage And Dosage Of Bentonite

Bentonite preparation

Bentonite is usually one of several paper machine retention system components.

For a correct bentonite function a proper preparation mode must be arranged. The preparation mode must respect time needed for material hydration. Therefore, the equipment is composed of a dispersing tank and a subsequent maturing tank followed by a dosing station.

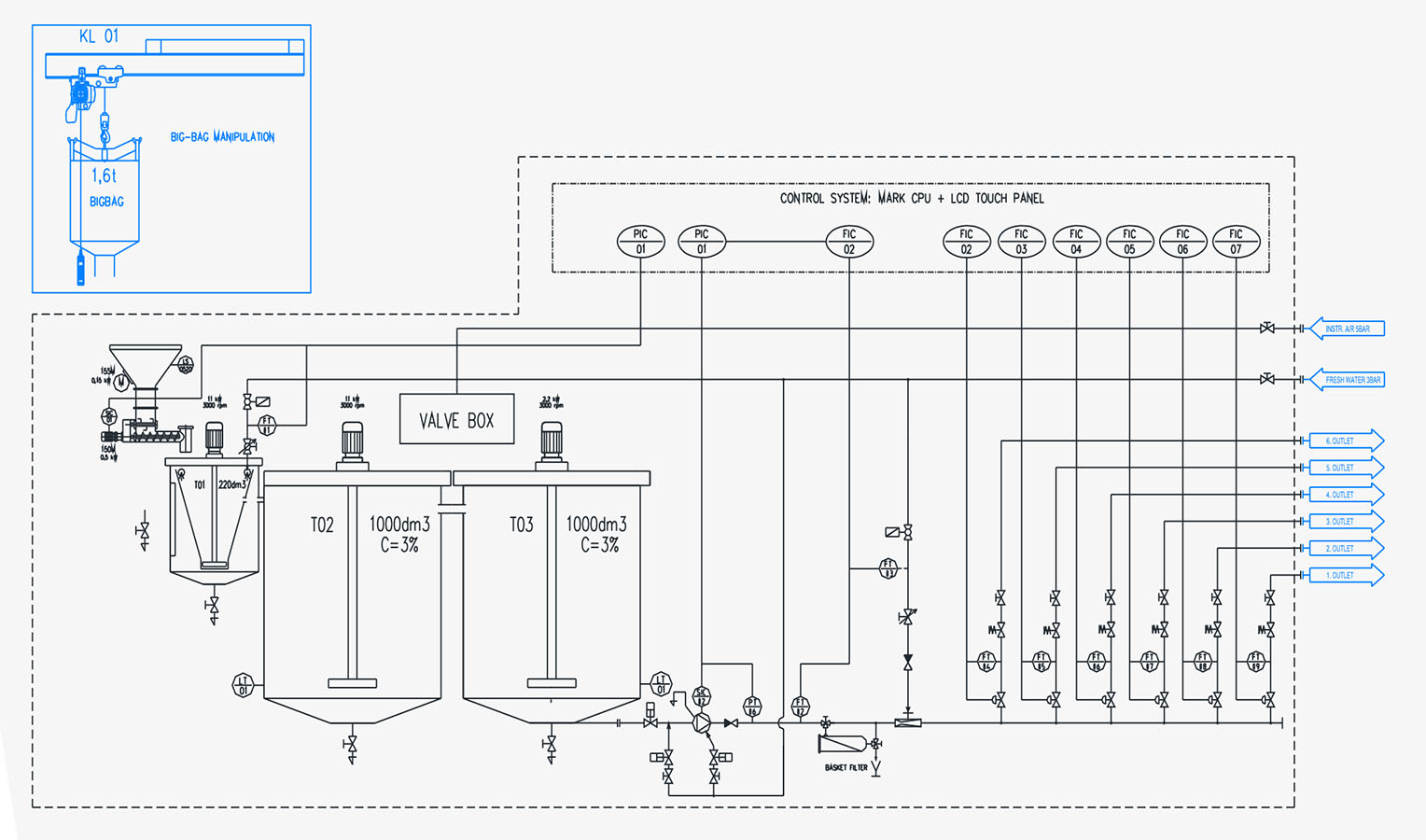

The bentonite preparation plant design presumes purchasing bentonite in “BigBag” type packs. Therefore, the station consists of a “Big-Bag” tower with a lifting device (or an existing crane is utilized), a hopper, a precise worm dosing device, a dispersing tank, a storage tank and necessary dosing screw (Mohno) pumps using the method of the ratio dilution down to the work concentration. Pure filtrate or thin stock (drawn from the stock pipeline close before the paper machine headbox)is used for the dilution. Such solution is significant for high-performance paper machines or generally wherever water consumption must be significantly reduced. The bentonite plant control system is designed similarly as the one in the polymer plants. Thus, the equipment is delivered with a control system or an existing PM control system is utilized.

Bentonite preparation plant main parts

- Slurry preparation (bentonite transport to a dispersing tank, a worm dosing station, weighing and mixing with water)

- Dispersing tank with a high-performance dispersing agitator and measuring & control elements

- Storage tank with a slow-rotating agitator

- Dosing screw pump with on-line dilution

- Electrics witch board with a control system

- Support frame

Parameters

- The equipment performance ranges from 3 to 150 kg/hr bentonite b.d. (the plant size is designed according to the paper machine output)

- Usual bentonite dose is 1 – 3kg/1 ton of paper

- The outlet concentration after the storage tank is usually 3 %

- The work concentration 0.3 %

The machinery design and safety comply with the EU and EAC industrial standards.