Equipment For ASA Sizing Agents Preparation And Dosage

A continuous preparation of mass sizing agent based on a principle of ASA (alkenyl-succinic anhydride) continuous emulsification in a solution of cooked cationic starch; works in a semi-automated or fully automated mode.

Process description

A solution of cooked cationic starch cooled down to a required temperature is continuously pumped to an emulsifying turbine. The ASA concentrate is continuously dosed into the starch flow before entering the turbine. A ratio of both flows is set in a control system. Emulsion of “oil in water“ type is formed in the turbine. The emulsifying process runs in an exactly defined mode to enable a maximum sizing agent efficiency. Except the other conditions, it is guaranteed above all by an exactly defined distribution of particles in the emulsion and by a process reproducibility. To run the process always under the same conditions, the energy put into the emulsifying process is measured. The result of the ASA concentrate emulsification in the starch solution is emulsion of particles of the 1to2 µm size.

The quantities of ASA, starch and energy put in the process are controlled by means of control circuits. An operator enters in the system basic input data (ASA dose – kg per ton, measured starch concentration, starch temperature after the cooler, ASA concentrate to starch quantity ratio, emulsifying turbine motor current, in case of more outlets also a ratio of outlets into particular pipeline branches).

By means of programmed sequences the control system maintains the correct operation mode to reach always optimal ASA particle sizes and the constant throughput of input raw material sand the final product)

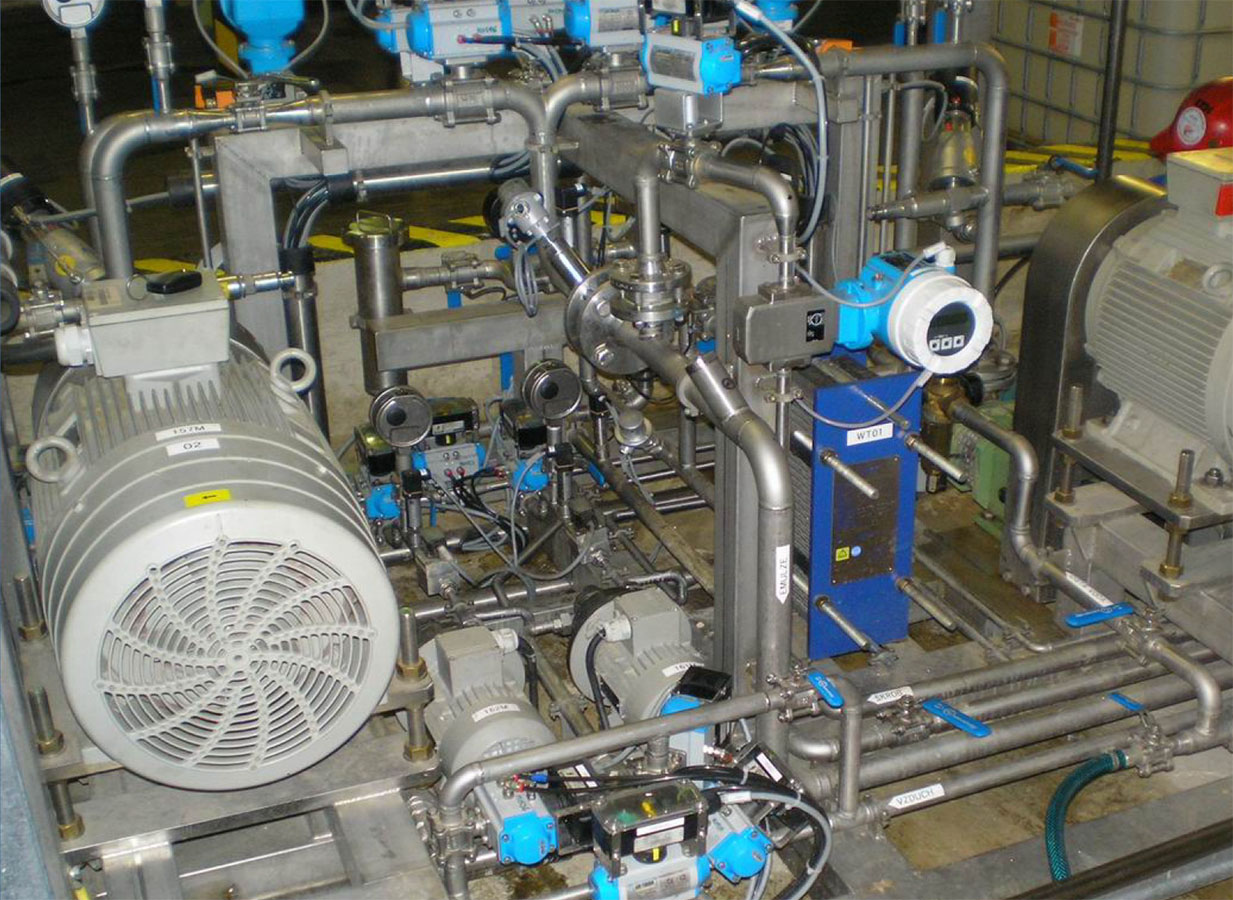

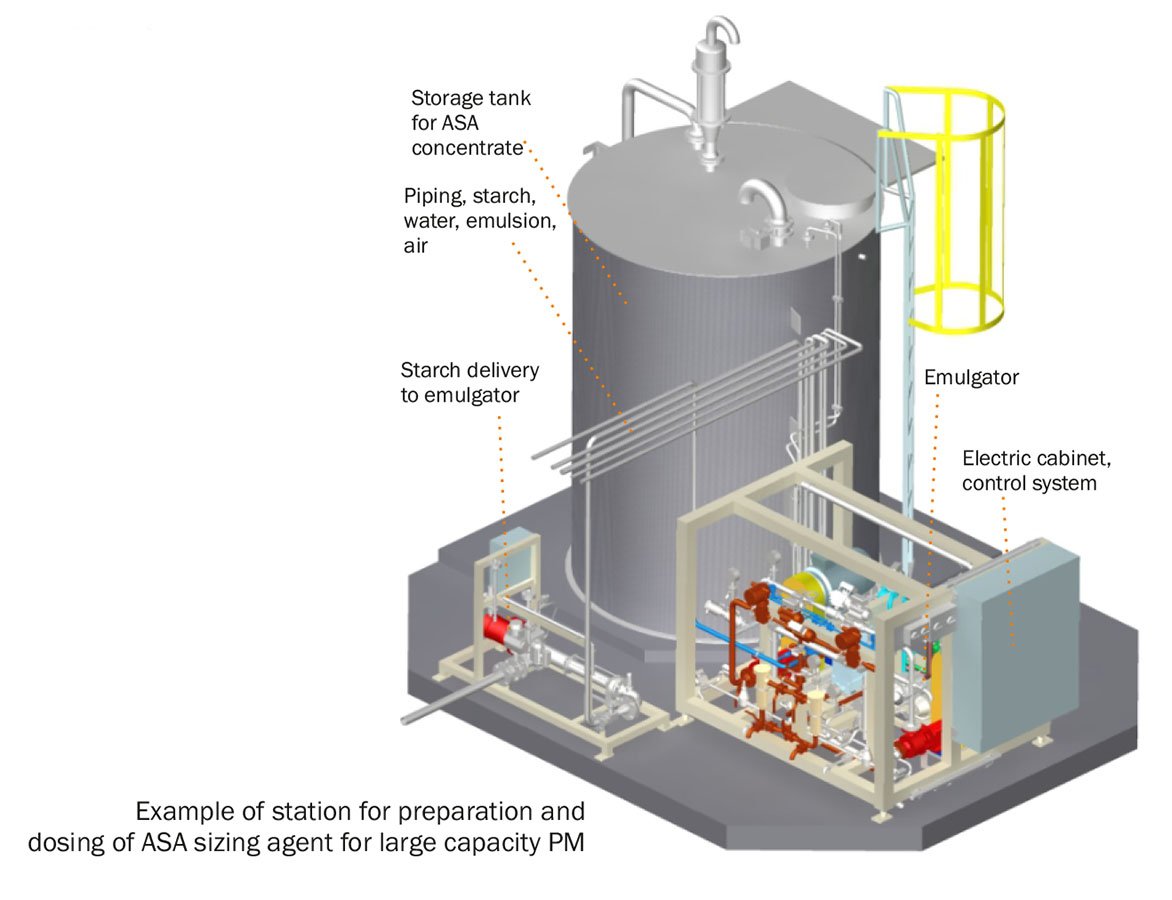

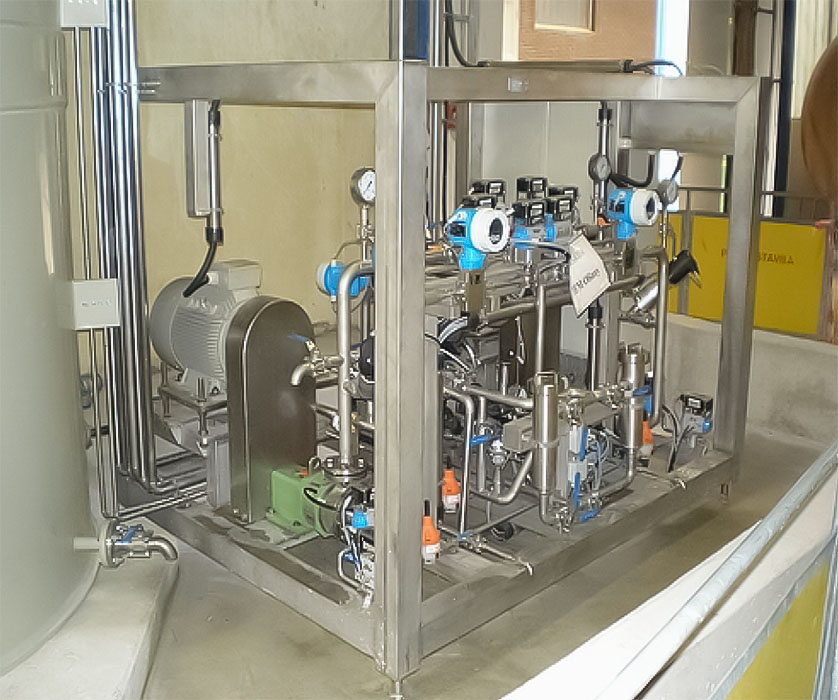

ASA station main parts

- ASA concentrate dosing pump measuring flow by means of a mechanical flowmeter (on demand amass flowmeter is installed)

- Starch dosing pump measuring flow by means of an inductive flowmeter (unless an existing pump of the same parameters is utilized)

- Starch plate cooler with a circuit for a tarch outlet temperature automatic control

- Emulsifying turbine with a drive and a current control circuit

- ASA sizer outlet distributor to several consumption points (if required) with an automatic flow control in each pipeline branch

- Set of measuring & control elements

- Electric switch board(wherever required)

- Support frame

Technical data

Principle: continuous emulsifying ASA concentrate in the solution of cooked cationic starch

Starch specifications

Starch sort: cationic – potato, corn, tapioca, alternatively another one if available

Concentration: 1 – 4 %, optimal 3.5 – 4 %

Starch temperature: 50 – 55 C

ASA specification

Commercial product C16 – C18

Performance specifications

Device with 1 outlet: for PM capacities of 5to80 tph

Device with 2 or more outlets: for PMs manufacturing multiply paper and cardboard grades – capacities of 5 to 30 tph

ASA concentrate dosing: 5to132lph

Starch dosing: depends on available concentration-to be designed as per particular conditions

Rated power input: no spare emulsifying turbine-25kW system with spare emulsifying turbine-48kW

(without starch dosing system)

starch dosing system without spare pump-2to6kW

starch dosing system with spare pump-4to12kW

Power feed: 3×400/600VAC/50to60Hz -to be specified in contractual documents

Size depending on make: 2.1 to 2.6 x 1.9 x 1.8 m

Process diagrams of various ASA station solutions

Simple ASA station

with starch pump and starch temperature control, 2 outlet branches, manual throughput control.

The ASA source are two parallel connected IBC containers; the starch source is in an existing

tank. The emulsifying turbine flow is controlled by a manual valve.

Fully automated ASA station

with an outlet distributor for a 3-ply paper machine.

The ASA source are two parallel connected IBC containers; the starch source is in an existing tank. The starch dosing station is installed separately. The emulsifying turbine flow is controlled automatically as well as the throughput in each branch.

Emulsifying station concept

- Built-in system of dosing and cooling starch (possibly with a separate system of dosing and cooling starch)

- No system of dosing and cooling starch

(dosing starch is enabled by an existing equipment) - One or more ASA dosing outlets to one or more dosing points

- Optional doubling critical positions to achieve a maximum reliability and a continuous operation with automatic switching to the spare position in a case of failure (concerns above all the ASA concentrate dosing pump, the starch dosing pump and the emulsifying turbine)

- A control system based on a brand-name CPU

- All the station elements are installed in a support frame, the station is a compact unit with connection points enabling a quick and simple installation

Software

- Depending on the concept and on the agreement with a customer, the equipment is delivered with a full control system incl. SW

- Or without a control system and SW (in such case the ASA station is controlled by a PM control system)

- The control system is based on Simatic S7-300 controlled by means of a colour LCD touch panel installed on a switchboard front door

- SW is always compiled with regards of particular conditions; it includes a set of sequences enabling a fully automated equipment start in a required sequence, a flow control of both ASA and starch, control of a mutual ASA/starch ratio and of a starch temperature

The machinery design and safety comply with the EU and EAC industrial standards

-

Category

Cultural / Industrial Length

4 feetWidth

6 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]