Dye Dosing Equipment

The design of the dye dosing systems depends on dye sorts used on particular paper machines. It depends whether the solutions are made of powder products or whether ready-made liquid dyes are dosed and dissolved by ratio before applying.

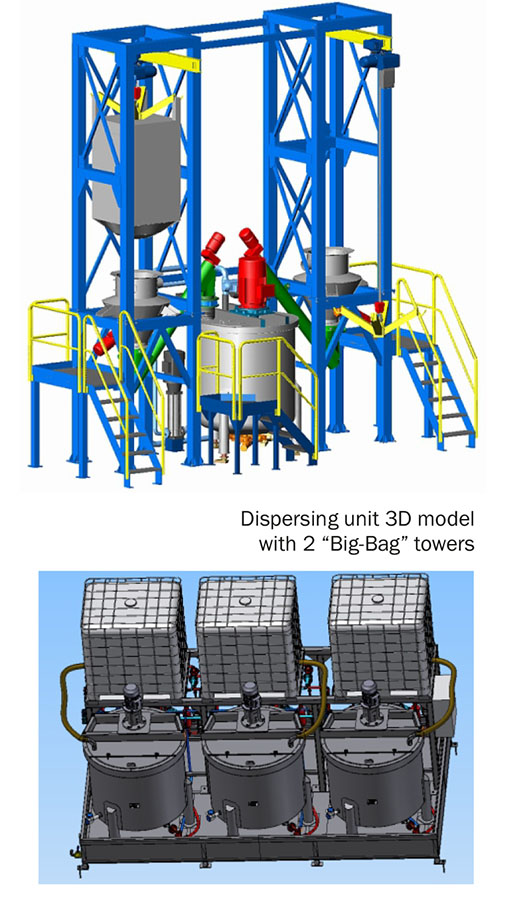

If dyes are prepared from powder products (for example FeOx slurries – iron oxide colour pigments for decor paper manufacture) the products are purchased either in 20 kg sacks or450-650-1000kg “Big-Bags”. The systems are similar in both cases.

The plant consists of a hopper able to contain hundred kgs of product (depending on a specific weight) – then either a 430 liter 3 hopper or a 1 to 2 m silo is used. A device for “Big-Bag” packaging is either delivered with a lifting tower or an existing proper lifting device is utilised. The powder material is furnished into the hopper and from there transported into a dissolving tank by means of worm conveyor in a defined mode. The conveyor drive is controlled by means of frequency converter to achieve high dosing accuracy.

The quantity of the product furnished into the tank is measured by means of strain gauge installed in the dissolving tank legs.

The covered tank contains a high performance dispersing agitator of a performance designed as per the dissolved material and the final concentration. The agitator work element is a Z-disc.

The agitator is driven directly. Its electric motor is driven by means off requency converter.Thus, the system variability concerning the usage mode is enhanced. The dissolving tank components are a water measuring system, a high-pressure wall and an agitator shower system, a material furnish air filtration and measuring & control (M&C) elements (such as level and temperature sensors). The solution is pumped either by a diaphragm pump driven by pressure air (of a high capacity and a long lifespan) or by a screw (Mohno) pump (with or without a performance control) or by a centrifugal pump. The solution is pumped into a storage tank of a volume designed from the given conditions

The storage tank volumes are in a very wide 3 range from 3 to 100 m . They are equipped with agitators to achieve homogeneity of the solutions or slurries. They are equipped with level sensors and emergency limit level sensors.

The design of the dosing stations depends on the required capacity in the range of tens up to thousands of litres per hour. The pumps are either an electrically driven diaphragm type or a screw type, always controlled by means of frequency converters. The solution or slurry throughput is measured by means of inductive flowmeter or mass flowmeter for higher demands. The dosing station is designed with regards to the performance and it contains either one or more pumps with needed fittings and M&C elements. Usually it is designed as a compact unit connected to the inlet and outlet pipelines by means of standard flanges. The connection to the power and signal cabling systems is designed with regards to the conditions on site.

Concentrator boxes as well as switchboards can be used or the M&C elements are connected directly to the mill control system in the main electric distribution cabinet.

Material:

- Plastics (PP, PE) or AISI 304/316 stainless steel depending on the used product

The tanks are either delivered fully assembled (standing on legs and fixed to concrete foundations by means of anchor bolts) or they are welded on site – in such case the

tank bottom is concrete grouted.

The systems for purchased liquid raw materials include proper pumps to enable a liquid dye delivery into proper 3 storage tanks (volume 3 to 100 m ) from 1 000 kg IBC containers. Usually diaphragm pumps driven by pressure air or screw (Mohno) pumps or centrifugal pumps are used; the choice depends on the raw material properties.

The storage tanks are equipped with agitators to enable a permanent slurry or solution homogeneity. The dosing station is designed in the very same way as described above.

The plants preparing and dosing FeOx slurries are similar to those used for china clay, PCC, GCC, TiO and others. 2 They differ only in their performances used for particular applications

The machinery design and safety comply with the EU and EAC industrial standards.