Dryers

Driyng part is the longest part of the PM. Its main purpose is to ensure the necessary drying capacity to reach the set PM performance. Maximal width drying part is 7,500 mm.

The drying parts types (the drying fabrics arrangement criteria):

Classical (conventional) design

- drying cylinders (∅ 1,250, ∅ 1,500, ∅ 1,800 mm)in two parallel rows with an upper and lower fabrics guiding.

Slalom fabric design

- drying cylinders (∅ 1,250, ∅ 1,500, ∅ 1,800 mm)in two parallel rows with one fabric guiding only or a single-row where the lower row is formed by guide rolls (non-heated, with grooves or bores) with complementary stabilization boxes. The main goal of such a setting is a permanent contact between the paper and the drying fabric to prevent breaks. The vacuum cylinders can be connected to the vacuum directly through a shaft on the drive side or form the part of the vacuum together with the stabilization box mounted tightly above this cylinder.

Yankee cylinder design

- the drying cylinder itself (∅ 4,000 mm) with or without fabric

Zero cylinder design

- one drying cylinder of a smaller diameter (∅ 1,000 mm) is installed in the beginning of the drying part with a complementary stabilization box.

Bearing structure types in the drying part

- cast iron stands with steel supports made of welded metal sheets and profiles (preferred solution with new structures)

- steel stands and supports (reconstructions or when complementing the load bearing structure)

Drying, cooling cylinders and guide rolls

- types, design and their location are described in the chapter dedicated to PM rolls. The bedding lubrication can be made as a central oil or grease lubrication. The cooling cylinders are located at the end of drying part and are necessary for decreasing of the temperature of the paper web, what leaves the drying part. The cooling cylinders are connected on the closed colling system.

Elements for a fabric guiding

- guides, stretching, sensors for position monitoring and fabric tension are described in separate chapters for a PM.

Fix and oscillating doctors

- described in an individual chapter for a PM.

Steam and condensation system, recuperation

-

- highly efficient multi-grade (type of cascade) drying system based on pressure regulation in cylinders. The process control is done either conventionally through anelectronic regulation or through a computer system.

The steam-and-condensate system together with recuperation and a good closed hood reduces significantly overall production costs in the energy field. Therefore our goal is to install a modern and economical steam-andcondensate system into the drying part, even though it might be economically more challenging; however, from the operational point of view it is more economic and effective. The system installation starts at the steam heads of the drying cylinders where a rotary or stationary (for higher speeds) siphon trap is installed in each drying cylinder.

The main task of the steam-and-condensate system is a suitable setting of a drying curve and its sufficient regulation for the given production assortment. The steam-andcondensate system control is done from an individual or central control system. The waste in the steam-and-condensate system is a condensate that goes back to the boiler house and a waste vapor. The temperature descent can be further used for air heating in recuperation.

Recuperation units use the waste heat from the warm and damp air leaving the drying part hood to heat a fresh air destined for the hood ventilation. The recuperation units are an integral part of modern drying parts either delivered or reconstructed and they are supplied by a subcontractors.

Drying part hood

The task of hood is to lower the thermal radiation from the drying cylinders into the air, to prevent a damp and warm air leak from the drying part into the hall and to lower the amount of air necessary for the vaporized water from the paper outlet by increasing its total moisture content.

Cleaning of drying fabrics

It prevents the fabric contamination which would cause a wrong dewatering and at the same time through a contact between the guide rolls to a web bundling on their surface which would consequently cause a partial or total damage of the fabrics. The cleaning is performed by subcontractors.

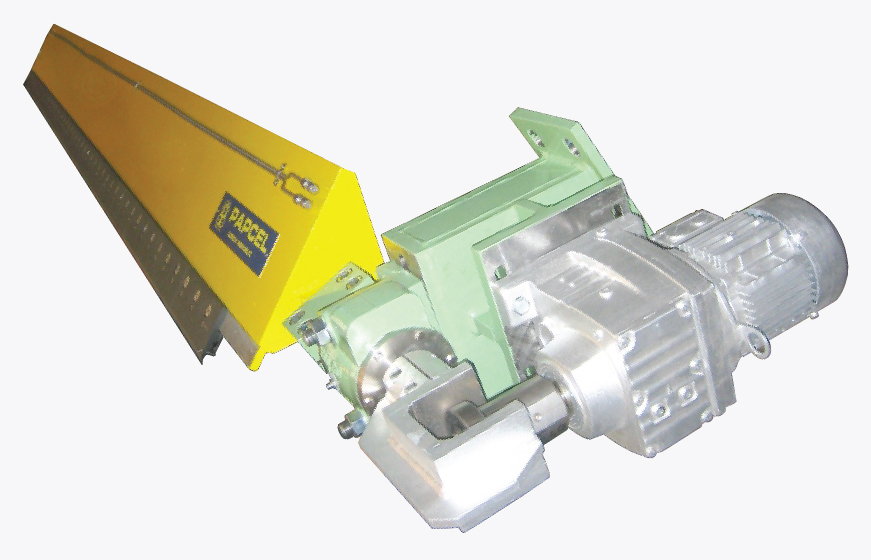

Slitter

It enables a guiding tail slitting into the POPE reel in case of a paper breakage. The device is located at the end of the drying part in front of the cooling cylinder. The slitter is supplied subcontractors.

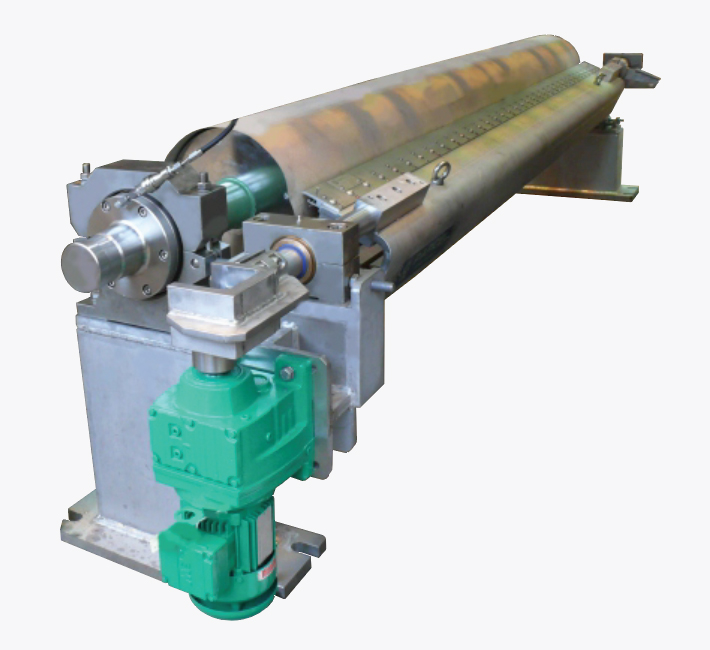

Variations of silent drying cylinders drives

A half-silent drive where the driving force from the drive unit of the adequate section is transferred on the last upper and lower cylinder only by a common plugging gearbox. Other cylinders in the lower and upper row are carried away by individual drying fabrics. „Silent drive” where the drying part is driven through the guide rolls of the drying fabrics. Oother drying cylinder: motor of the drive is located right on the shaft of the guide roll from the service side.

Paper rope threading

The most common version is a double-rope over the whole drying part. We use an automatic threading ropes stretching, i.e. when the paper is threaded, the ropes are stretched only as necessary so that the machine would run continually.