Doctors

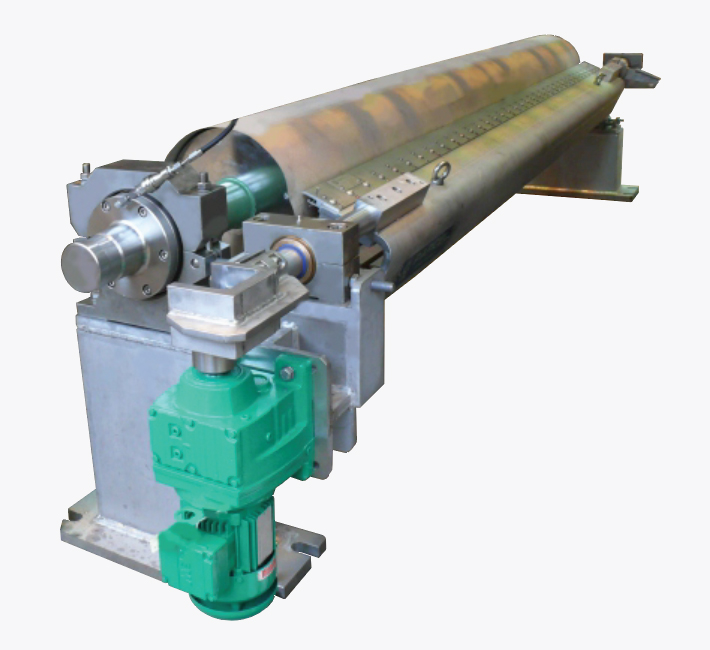

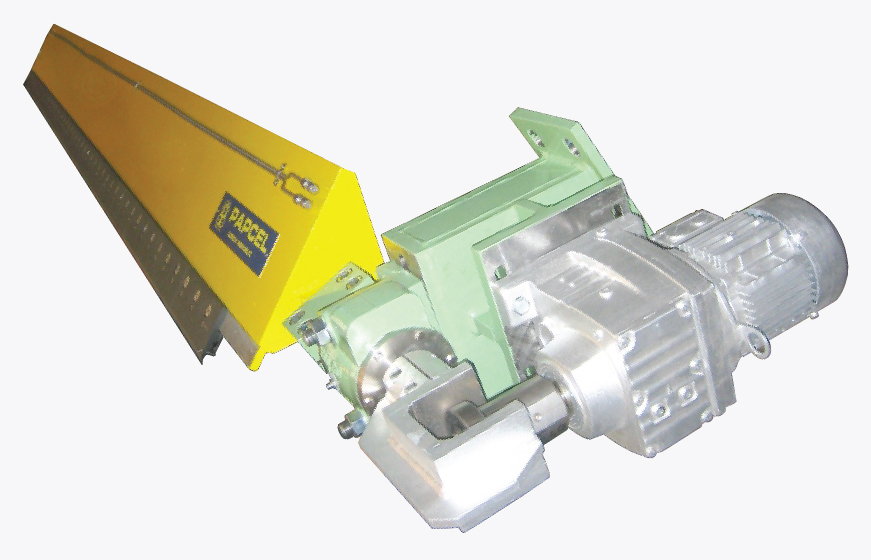

Doctors are used for cleaning of rolls and cylinders in paper machines. Each doctor is specially constructed to fit an actual application in a PM so that it meets all given requirements – mainly the roll cleaning. There- fore it is not possible to relocate it to other positions, since its function would be violated which may lead even to a roll damage.

Some rolls are operating as pressure vessels (with internal overpressure), are designed and tested in compliance with EU standards. If required, the rolls are delivered with corresponding certificates.

Doctor types:

- Cleaning

- Creping

- Breaking

Design

The doctors are delivered with a blade loading:

- By their own weight and manual control

- Using pneumatic cylinders

- Using hose blade holders

- With pneumatic oscillation

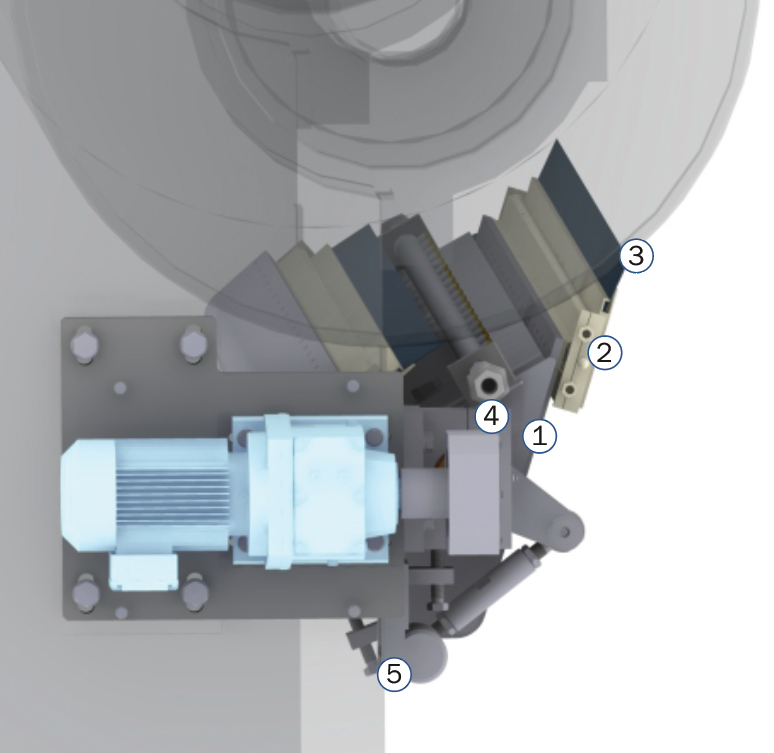

To improve the scraping effect, the doctors are equipped with an oscillation device. The movement is usually created by an eccentric pin which is located in the electric motor with a gearing device. The device can be delivered with a lubrication tube as well.

Ovládání škrabáků

The doctors can be delivered with the blade pressure made by self-weight and with manual control, or with pressure and tilting what is done by force of air-cylinders. In doctors with tube holders, the pressure and tilting is made by air-hoses all over the length of the blade. The hoses are the part of doctor design.

The doctors with the pressure and tilting by the air cylinders or the doctors with tube holders are connected with the delivered control box or with PM control panel. The operating can be done manually by the pneumatic switchboard and by setting of requested pressure by reducing valve according to the chart, what is placed on the control box.

Main parts

- Doctor beam (1)

- Blade holder (2), blade (3)

- Pins+bedding(4)

- PM fixing consoles (5)

Material

- Fully stainless steel version (the wet part of the machine)

- Stainless steel parts + covered carrier

- Common steel, including anticorrosive paint (the dry part of the machine)

The material quality depends on customer’s request or is made in a standard way of stainless steel and common steel. An oscillating electric motor can be delivered with a protection up to IP 68, pneumatic control cylinders are made of standard aluminum or non-corroding steel.

Accessories

- Frequency converter

Scope of delivery

-

- Construction design + devices according to main parts description

- Parts for overall control elements connection for the PM control

- Independent control panel

-

Category

Paper Machine Section

IndustrialPaper/CulturalPaper/SpecialtyPaper

Company Presentation

[elementor-template id="3268"]