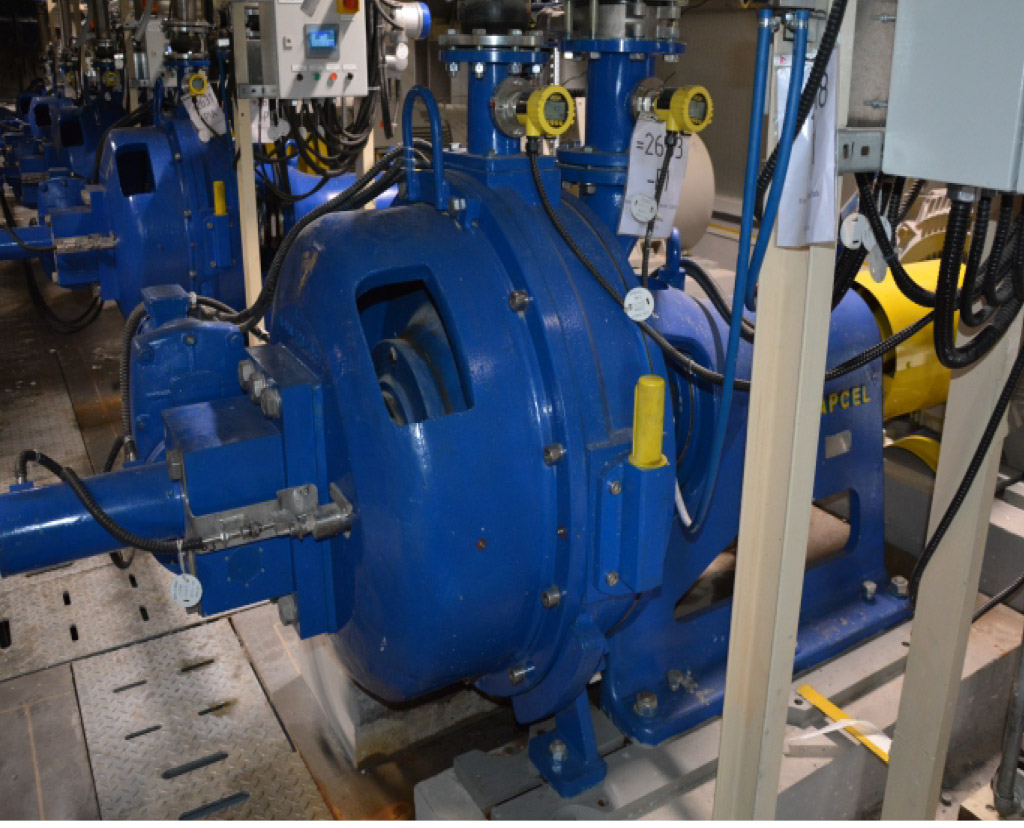

Disc Refiners Deflakers

Disc deflakers D and DR are designed for deflaking waste paper, machine broke, chemical pulp and knotter screening pulp and other sorts of rejects from separators.

Disc refiners D, DR a 2DR are used for refining paper stock. A wide range of refining discs provides perfect mastering of the whole refining process from fiber cutting up to high fibrillation.

Design

Refiners and deflakers are delivered as single-disc machines with one working zone (sizes D1, D2, D3, DR2, DR3) or as double-disc machines with two working zones (size 2DRT2, 2DRT3). The capacity and efficiency of deflakers and refiners is continuously adjustable in a direct dependence on actual machine load ranging from 7 to 250 tpd.

Functional elements

Wide range of refiners allows perfect operation of the all refining process from shortening to the high fibrilation.

Setting of requested technological parameters and provision of the operation is realized by the sensors of steam pressure installed on inlet and outlet pipeline. Operating control and automatic regulation of disc refiners and deflakers is based on a control with automatic unit. When the machine is installed into a computer-controlled line, the computer fully provides the regulation of refining and deflaking processes.

Main parts

- Machine unit (1): machine body completed with bearing housing and removable working box

- Stuffing box (2)

- Functional elements (3): stator and rotor plate with refining or deflaking functional elements

- Loading mechanism (4): lifting gearbox, electric gearbox and mechanism for measurement and control of elements movement

- Electric motor (6)

- Base rails (7)

Material

- Refining and deflaking functional elements are made of special alloyed cast steel

- The rotor, cover and working box are made of stainless steel

- The stuffing body is made of stainless steel

- Other parts are made of structural steel with an outer coating of polyurethane double-component coating

Accessories

- Local control unit

- A set of tools for repairing the main shaft setting and for manipulating with a rotor covered with garnitures

- Pressure sensors with manometers and pressure switch (not part of standard delivery)

Machine design and work safety are in compliance with the EU standards and EAC.

| Technical parameters | |||||||

|---|---|---|---|---|---|---|---|

| Machine type | ∅ D1 (mm) | ∅ D2 (mm) | A (mm) | B (mm) | C (mm) | E (mm) | Weight without motor (kg) |

| D10-D-3 | DN 80 | DN 80 | 810 | 692 | 970 | 1 580 | 524 |

| D10-D-4 | DN 80 | DN 80 | 910 | 692 | 970 | 1 882 | 546 |

-

Category

Cultural / Industrial Length

4 feetWidth

12 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]