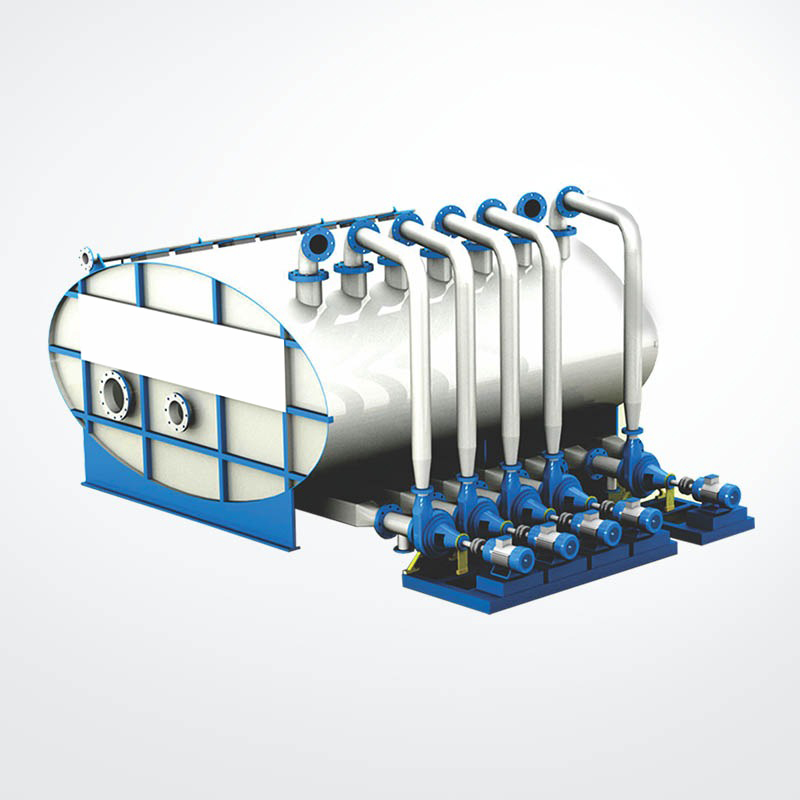

De Inking Cell

The purpose of de-inking is to remove the printing inks and stickies that might affect the paper-making process. In a de-inking process, ink is detached from the fiber. Flotation technology provides a high yield of fibers and simple handling with maximum operating reliability.

Principle Of Operation

The JMC De-inking cell consists of a number of cells in series with an elliptical cross-section with a baffle extending over the entire length to separate the suspension chamber from the foam collecting chamber. Air (at the atmospheric pressure) and pulp stock are introduced into the cell through injectors. Flow-through nozzles generate a vacuum which generates microturbulence resulting in widely ranging bubble sizes enabling efficient removal of ink of particles. This enhances brightness to a high degree and reduces dirt specks and stickies. The injectors optimize the quantity of air injected and the size of the bubbles generated.

The pulp stock freed from the ink is pumped from the bottom of one cell to the next cell. The ink-laden foam overflows into the foam chamber with the help of a motorized paddle. The flotation process is operated in a continuous mode and helps to remove ink particles efficiently. Since the cells are interconnected level is controlled through a level transmitter on the entire flotation machine.

The primary flotation stage ensures the highest possible stock purity and the secondary stage optimizes yield. A Deaerator cyclone removes air from the stock and usable fibers are recovered from the foam.

Salient features of the

JMC De-Inking Cell, Flotation Model

- The highest possible degree of brightness is achieved

- Improved optical cleanliness in recovered paper stock.

- No sizing restrictions

- Single-level control loop operation.

- Optimized flotation yield at the secondary stage without loss of brightness and cleanliness.

- Very low fiber loss in the de-inking process as the foam is treated in a cascade process.

-

Category

Stock Preparation Sub Category

White Waste

Company Presentation

[elementor-template id="3268"]