Conveying Systems

Conveyors are used for conveying waste paper, bales of chemical pulp or bags with chemicals to pulpers, for removal of rejects from separators, for conveying dry broke to pulpers or for paper rolls handling.

Design

The material is unloaded on the ingoing part of the conveyor. According to the type of delivery, the conveyors are divided into embedded or overhead. Depending on the conveyed material, they are divided according to their construction to rolling (with or without belt), chain (with or without belt), and chain with steel lamellas

For a sideway transport, grips can be installed on the belt to prevent a possible material slipping. Those can be made of metal (U or L shaped) or vulcanized rubber.

Conveying systems consist of one conveyor or a whole conveyor route. They are designed in accordance with the way the line is operating, its input (tons per day) or depending on the conveyed material and specific customer requirements. In addition to the systems described above, we also deliver elevators, cellulose bales turn-over equipment, automatic dewiring and bale cutting equipment, and conveyors for chemicals.

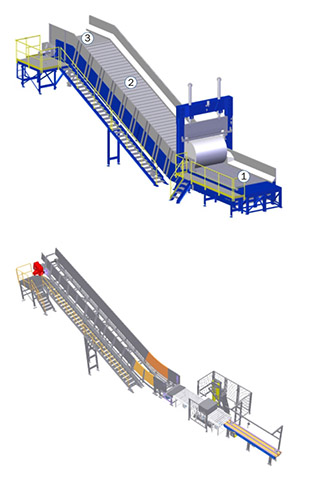

Main parts

- Loading part (1)

- Carrying part (2)

- Unloading part with a drive (3)

These basic parts vary in shape and design. The ingoing part may comprise of a loading conveyor modified according to particular requirements (with a belt, steel plates, chain-belts, rolls etc.); an elevator; handling platforms; bale turners; and a preparatory storage system etc.

Material

- Materials used for conveyors respect customer’s requirements and depend on paper production technologies with regard to machine positioning and the type of technological line

Standard accessories

according to the type of conveying system

- Manual lubrication of chains

- Safety features (STOP buttons, rope switch, flash light with sound signalization)

- Electric part, installation of electric motor without connection to the terminal board

Optional accessories

according to the type of conveying system

- Waste roll cutter with a lift and clamping

- Tilting table

- Service bridges

- Chutes

- Pneumatic wire hand cutting with travel for pneumatic shears

- Frequency converter

- Control system

- Control panels

- Weighing equipment (static or in motion)

- Metal detector

- Bar code scanner, etc.

Machine design and work safety are in compliance with the EU standards and EAC.

| Technical parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Type of pulper | ~L1 / type L(mm) | ~L1 / type Z(mm) | ~L2(mm) | ~H1(mm) | ~H2(mm) | ~B1(mm) | ~B2(mm) | Max. carrying capacity (kg/m2) | Electric motor ouput (kW) |

| OVERHEAD | |||||||||

| LCV-14 | 16 780 | 18 780 | 2 000 - 8 000 | 4 450 | 6 080 | 1 300, 1 500, 1 800 | 1 000, 1 200, 1 500 | 400 - 500 | 3 - 11 |

| MCV-14 | 18 200 | 20 200 | 2 000 - 8 000 | 5 150 | 6 700 | 1 300, 1 500, 1 800 | 1 000, 1 200, 1 500 | 400 - 500 | |

| LCV-20 | 18 500 | 20 500 | 2 000 - 8 000 | 5 100 | 6 850 | 1 300, 1 500, 1 800 | 1 000, 1 200, 1 500 | 400 - 500 | 3 - 15 |

| MCV-20 | 19 400 | 21 400 | 2 000 - 8 000 | 5 580 | 7 250 | 1 300, 1 500, 1 800 | 1 000, 1 200, 1 500 | 400 - 500 | |

| LCV-30 | 20 680 | 22 680 | 2 000 - 8 000 | 6 200 | 7 820 | 1 300, 1 500, 1 800 | 1 000, 1 200, 1 500 | 400 - 500 | 4 - 15 |

| MCV-30 | 22 000 | 24 000 | 2 000 - 8 000 | 6 580 | 8 410 | 1 300, 1 500, 1 800 | 1 000, 1 200, 1 500 | 400 - 500 | |

| LCV-40 | 21 300 | 23 300 | 2 000 - 8 000 | 6 550 | 8 250 | 1 300, 1 500, 1 800 | 1 000, 1 200, 1 500 | 400 - 500 | 4 - 18.5 |

| MCV-40 | 21 400 | 23 400 | 2 000 - 8 000 | 6 600 | 8 300 | 1 300, 1 500, 1 800 | 1 000, 1 200, 1 500 | 400 - 500 | |

| LCV-50 | 22 185 | 24 185 | 2 000 - 8 000 | 6 900 | 8 500 | 1 300, 1 500, 1 800 | 1 000, 1 200, 1 500 | 400 - 500 | 5.5 - 22 |

| LCV-65 | 22 450 | 24 500 | 2 000 - 8 000 | 7 000 | 8 750 | 1 300, 1 500, 1 800 | 1 000, 1 200, 1 500 | 400 - 500 | 5.5 - 30 |

-

Category

Cultural / Industrial Length

4 feetWidth

12 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]