Cleaners for Fine Impurities Cleaning

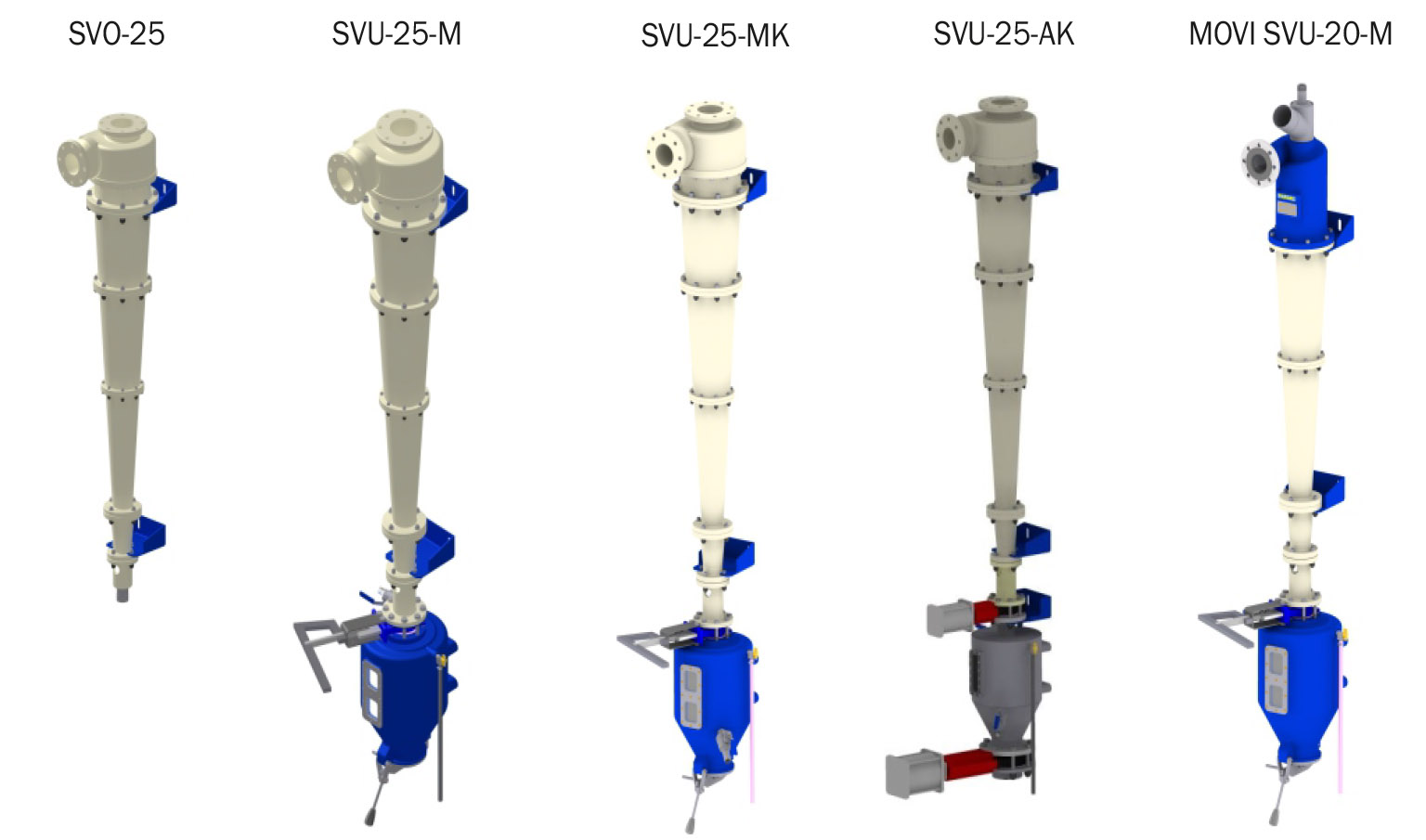

Low-density cleaners VO (spiral SVO) are used for a highly efficient fine separation of specifically coarse, sticky and conic impurities in paper machine approach part systems, in mechanical pulp mills and in waste paper processing lines. Moreover, they reliably remove sand and other larger impurities. They provide possibility to be operated up to 2 % density of the cleaned stock. The reject nozzle diameter is 30 mm.

Low-density cleaners VU (spiral SVU) are used for a highly efficient fine separation of specifically coarse, sticky and grit impurities from thin stock, particularly in a multistage station of bigger cleaners as an end part for final cleaning of rejects in pulp mills, in waste paper processing lines and in paper machine approach part systems. Moreover, they reliably remove sand and other larger impurities. The cleaners provide a possibility to be operated up to 2 % of stock consistency. The reject nozzle diameter is 30 mm. The collecting box MK enables to choose both periodical and continuous rejects discharging.

Combined cleaners MOVI SVO, MOVI SVU belong to a family of centrifugal cleaners with a free vortex and discharge of separated impurities into a collecting box or collecting piping. These cleaners work reliably in the separation of specifically heavy and light impurities, as well as in deaeration of the paper stock.

Opened cleaners MOVI SVO are designed for a highly efficient fine separation of specifically coarse, light, sticky and grit impurities from thin stock. The separation of light impurities (polystyrene etc.) runs parallel to the stock deaeration. Moreover, they reliably remove sand and other larger impurities. The cleaners provide the possibility to be operated up to 2 % of stock consistency. The cleaners MOVI SVO usually run in multistage working stations arranged according to actual on-site operating conditions.

Closed cleaners MOVI SVU are utilized namely as a final stage for a final cleaning of the reject. The closed cleaners are joint in multistage stations. These are installed in waste paper processing lines, in paper machine approach flow systems, in groundwood-making plants and everywhere, where it is needed to minimalize the reject quantity.

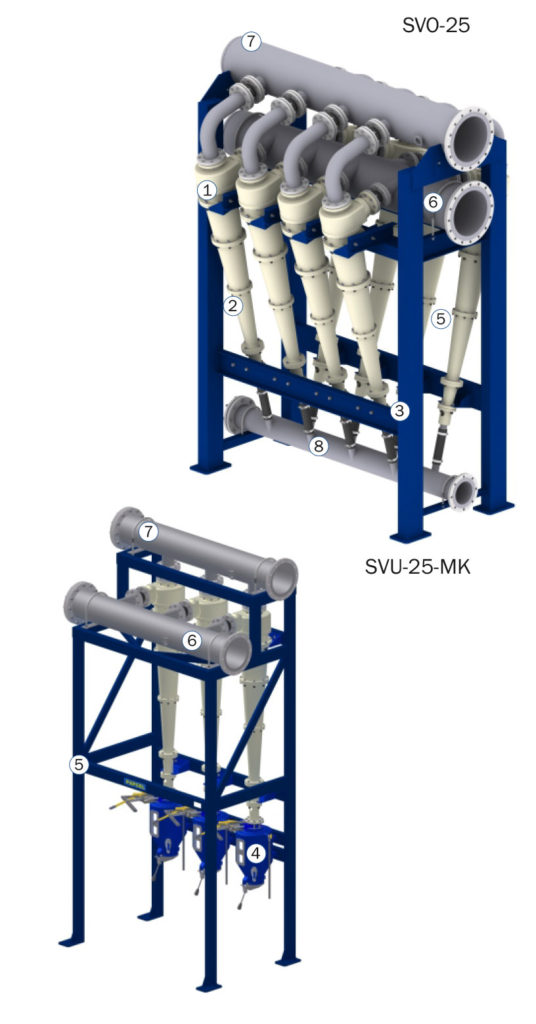

Main parts

- Inlet body – head (1), working body-cone (2)

- Separating body with sight glass (3)

- Collecting box with pneumatic gate valves – automatic control

- Collecting box (4) – mechanical control

- Steel supporting stand (5) – if the cleaners are delivered in a station

- Distributing pipeline of input (6) and output (7) is closed at one end with an arched bottem and at the other end with a flange

- Rejects pipeline (8) is closed with flanges

Material

- Cleaners are manufactured in several type sizes always based on a uniform design with a high unification of the parts

- Cleaners VO, SVO, VU, SVU, MOVI SVO, MOVI SVU are in standard combination of stainless steel-plastics

- Collection box – design M, MK and A is made of grey cast-iron, design AK is made of stainless steel

Machine design and work safety are in compliance with the EU standards and EAC.

| Technical parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Type | Optimal throughput (l/min.) | Consistency (max. %) | Max. inlet pressure (kPa) | L x W x H (mm) | ∅ D (mm) | ∅ D1 (mm) | ∅ D2 (mm) | ∅ D3 (mm) | Weight (kg) |

| VO-15 | 570 - 690 | 1.6 | 400 | 1 490 x 220 x 350 | 150 | 63 | 80*) | 63*) / - | 32 |

| VU-15-M, MK | 590 - 690 | 1.6 | 400 | 2 380 x 620 x 790 | 150 | 63 | 80*) | - | 108 |

| VU-15-A | 590 - 690 | 1.6 | 400 | 2 010 x 850 x 350 | 150 | 63 | 80*) | - | 108 |

| SVO-25 | 1 800 - 2 100 | 2 | 400 | 2 340 x 385 x 485 | 260 | DN 100 | DN 125 | 63*) / - | 53 |

| SVU-25-M, MK | 1 800 - 2 100 | 4.5 | 400 | 3 220 x 620 x 790 | 260 | DN 100 | DN 125 | - | 140 |

| SVU-25-A | 1 800 - 2 100 | 4.5 | 400 | 2 820 x 850 x 485 | 260 | DN 100 | DN 125 | - | 140 |

| MOVI-SVO-20 | 1 200 - 1 400 | 2 | 400 | 2 210 x 310 x 460 | 210 | DN 80 | 100*) | 63*) / G1 1/4” | 75 |

| MOVI-SVU-2-M | 1 200 - 1 400 | 2 | 400 | 3 100 x 620 x 790 | 210 | DN 80 | 100*) | - / G1 1/4” | 170 |

-

Category

Cultural / Industrial Length

12 feetWidth

6 feetHeight

10 feetWeight

580 kgSpace Require

14 sq. feet

Company Presentation

[elementor-template id="3268"]