Chipper House

Wood Logs having Diameters from 50- 250 mm and lengths of 6 meters are received in the factory. Debarking of these logs is carried out either at the source or in the factory as the bark is a Non- Fibrous material & not useful for the pulping process. Debarked Logs are fed to the chippers to cut into approx. size of 25 mm x 25 mm x 3 mm thick. So that, during cooking the liquor is impregnated into the chips to facilitate the cooking process. The Chips from the chipper are fed to the screens, where accepted chips are, and oversized materials & dust are separated. The accepted chips are stored in the Silo, from where it is fed to the Digester. The Oversize material is taken to rechipper & the chips are again fed to the screen.

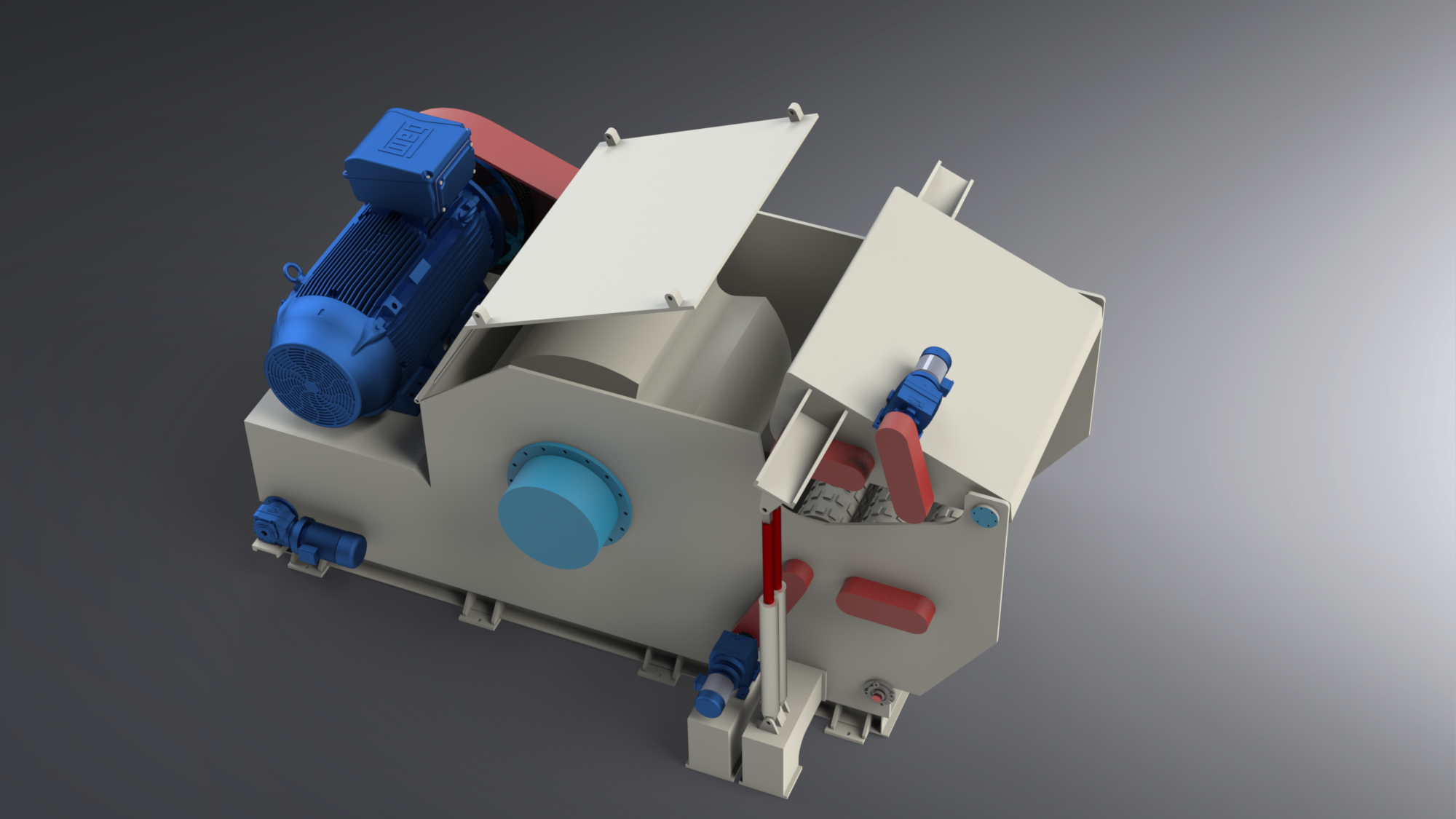

Chipper:

The Chipper consists of a fabricated drum with 4 No. chipping knives & 1 no. dead knife. 2 Nos. Feed rolls are provided in front of the chipper to pull the logs. The chipper is normally provided with a startup motor with VFD to avoid the Jerk load during the Startup.

Generally, the Hydraulic system is provided for the hood & Dead knife changing. Limit switches & Rotation sensors are provided to avoid accidents.

Chip Screen:

Chip screen is the triple-deck- two separate accepted chips, oversized chips & dust. The screen is a rope hanging with an oscillation arrangement. The accepted chips- mesh size is 40 x 40 mm and Dia. 6 mm perforated screen for the dust. The screen has got movable eccentric assembly with bearing housing & base frame. One side is coupled with Vat & another side with a counterweight for balancing.

Rechipper:

Rechipper is identical to the main chipper with lesser capacity to feed the oversized material received from the chip screen. It has got three no. of fly knives on the drum & one no. of the deadly knife.