Horizontal Broke Pulpers

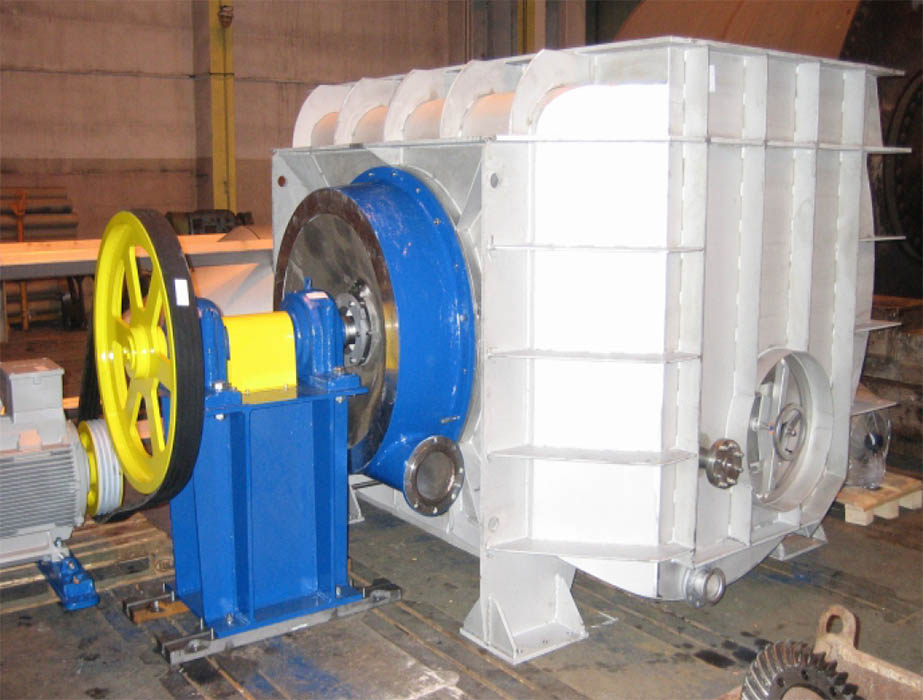

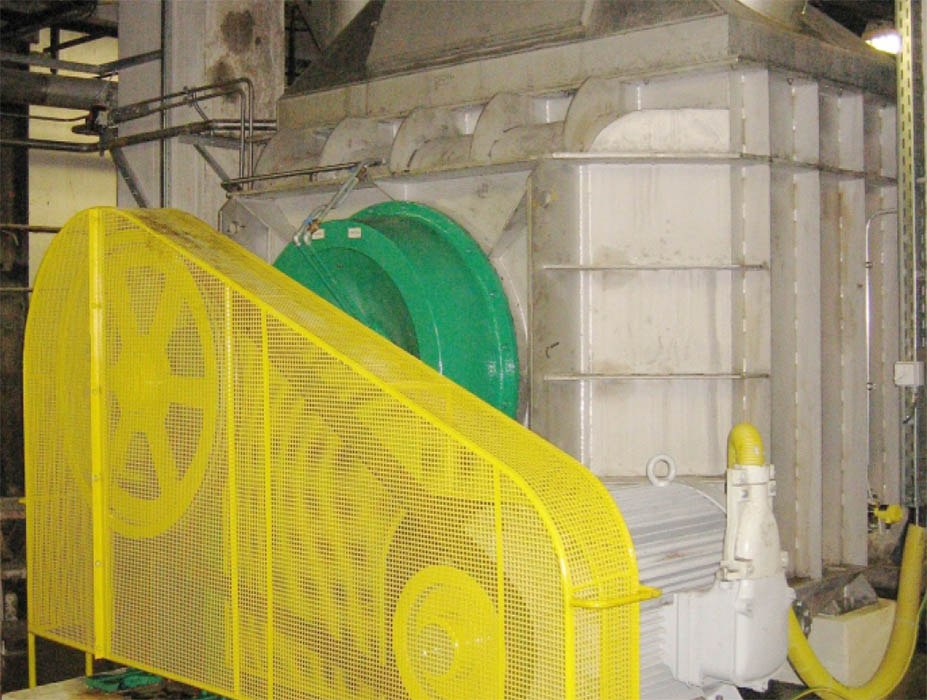

Horizontal broke pulpers HB are designed for pulping wet and dry broke from paper and cardboard machines. They include tank and horizontally arranged pulping elements with a base and a driving unit.

Design

The HB pulpers are designed and delivered according to the given paper grade, paper web width and PM performance. The rounded shape of the tank increases the pulping process efficiency. A deflector, installed above the pulper rotor, prevents stock splashing. The pulper stator can be cleaned by a washing water led directly into the functional elements. The output branch of the pulped stock from the output body and the stock discharge branch of the chest are selected according to actual operating conditions. Unnecessary branches can be closed by blind flanges. The pulper tank is provided with a manhole for an easy access to functional elements. According to actual conditions, the pulper can be completed with a chute and a sliding shower pipe for keeping the broke in a required direction. Performances shown in the chart apply to a dry broke under the reel and a wet broke under presses.

Machine design and work safety are in compliance with the EU standards and EAC.

Machine parts

- Welded stainless chest (1) with a manhole

- Functional elements: rotor (2), vaned rim (3), stator screen (4)

- Outlet body (5)

- Bearing housing (6)

- V-belt drive with a cover (7)

- Electric motor on slide rails (8)

Material

- All parts coming in contact with the stock are made of stainless steel

- Output body and functional elements are made of special wear-resistant stainless cast steel

Scope of delivery

- Complete machine according to main parts description with a drive (standard delivery without electric motor)

- Accessories upon customer’s request

| Technical parameters | |||

|---|---|---|---|

| HB-14 | HB-20 | ||

| Tank volume | m3 | 14 | 20 |

| Outlet body diameter | D1 | DN 250 | DN 300 |

| Inlet body diameter | D2 | DN 100 | DN 100 |

| Machine width (X) | mm | 3 650*) | 4 700*) |

| Machine height (Y) | mm | 2 900*) | 3 000*) |

| Machine length (Z) | mm | 5 400*) | 5 800*) |

| Dry broke capacity | t/hr | 6.5 - 9 | 11.5 - 16 |

| Wet broke capacity | t/hr | 16.5 - 21.5 | 29 - 39.5 |

| Electric motor output | kW | 132 | 160 / 200 |

| Total machine weight | kg | 7 160 | 9 430 |

-

Category

Stock Preparation Section

Recycled OCC-DSOCC/White Waste/Mix Waste

Company Presentation

[elementor-template id="3268"]