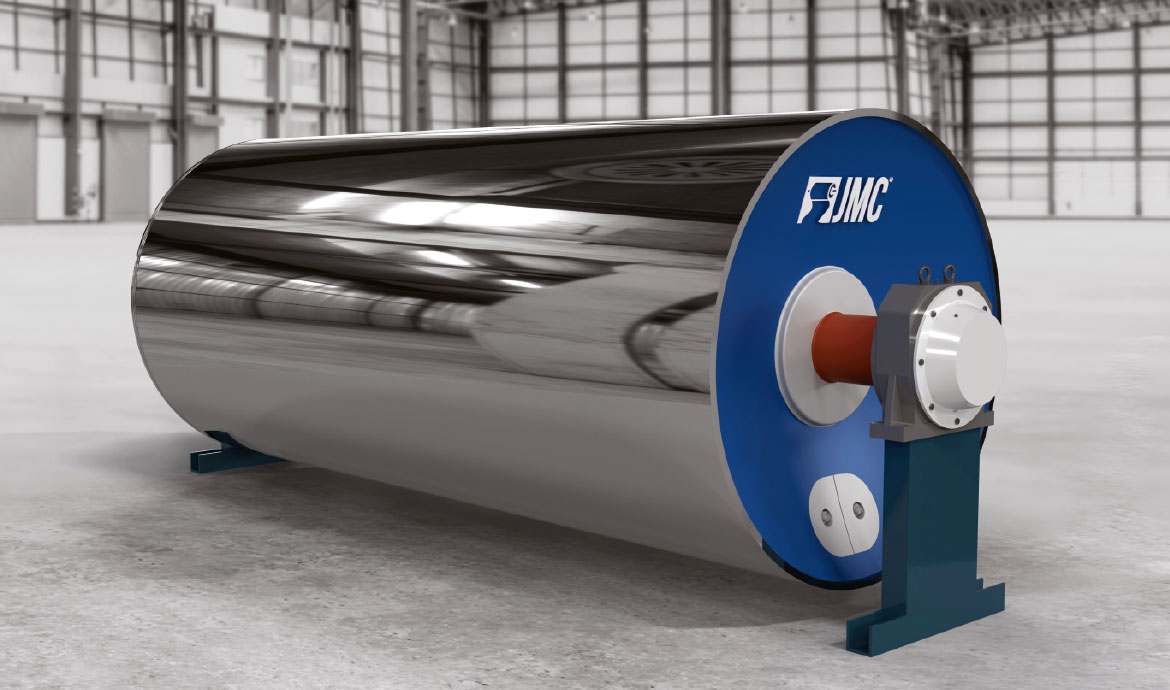

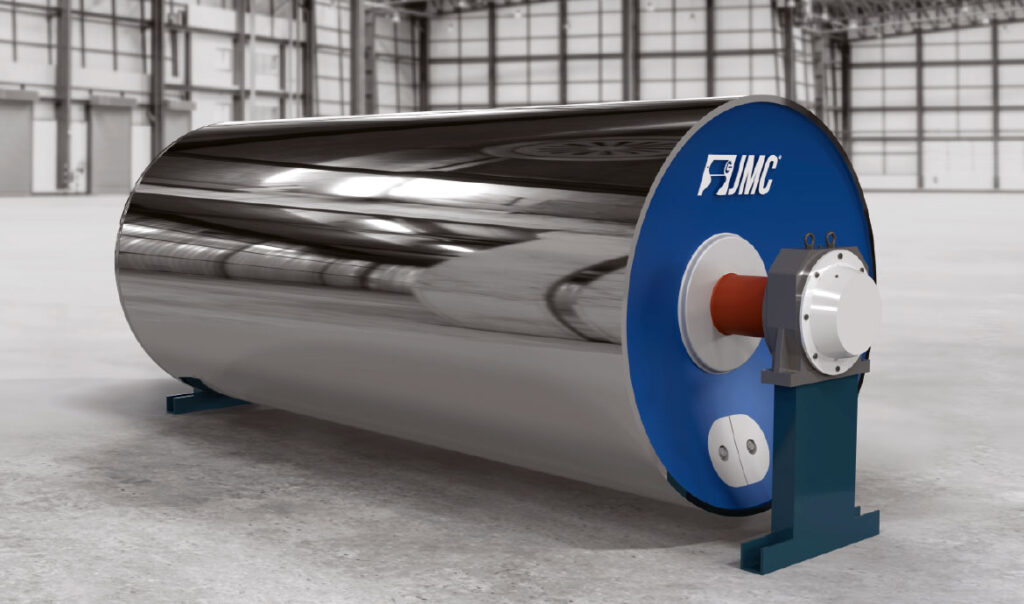

In the realm of paper manufacturing, the drying process is a critical stage that significantly influences the quality and efficiency of the final product. At the forefront of innovation, JMC Paper Tech Pvt. Ltd. has carved a niche for itself by developing a sophisticated manufacturing process for Steel Dryers. This blog post delves into the intricacies of this process, highlighting how JMC Paper Tech has mastered the art of customization to meet the unique needs of its customers and specific project requirements.

Manufacturing Process: Tailoring Steel Dryers to Perfection

JMC Paper Tech’s manufacturing process for Steel Dryers is a testament to precision engineering. Unlike generic, one-size-fits-all solutions, JMC Paper Tech takes a customer-centric approach, offering tailor-made Steel Dryers that align with the exact specifications of each project. The process begins with a comprehensive assessment of the customer’s needs, project requirements, and environmental considerations.

- Customization for Project Specifics: JMC Paper Tech recognizes that no two projects are identical. Thus, the company’s engineers meticulously analyze factors such as paper grade, production speed, and environmental conditions. This information serves as the foundation for crafting Steel Dryers that optimize drying efficiency and overall operational performance.

- Quality Controls: Ensuring Excellence at Every Stage: To maintain the highest standards, JMC Paper Tech employs rigorous quality control measures throughout the manufacturing process. From the selection of raw materials to the final inspection, each Steel Dryer undergoes meticulous scrutiny. The company adheres to international quality standards, ensuring that customers receive a product that not only meets but exceeds expectations.

- Material Selection: The Heart of Steel Dryers: JMC Paper Tech utilizes high-quality steel alloys in the manufacturing of Steel Dryers. The choice of materials is a crucial aspect that influences the mechanical properties and longevity of the dryers. Steel Dryers are renowned for their strength, durability, and resistance to corrosion, ensuring a prolonged operational life.

Mechanical Properties and Features: Unlocking the Potential of Steel Dryers

- Strength and Durability: Steel Dryers are prized for their exceptional strength, providing a robust and reliable solution for the demanding conditions of paper manufacturing. The inherent durability of steel translates to a longer lifespan and reduced maintenance costs.

- Corrosion Resistance: Unlike traditional cast-iron dryer cans, Steel Dryers are inherently resistant to corrosion. This resilience is particularly advantageous in paper mills, where exposure to moisture and chemicals is inevitable. The corrosion-resistant properties contribute to a more sustainable and cost-effective solution.

- Temperature Regulation: Steel Dryers offer superior temperature regulation capabilities, crucial for achieving precise and efficient drying in the paper manufacturing process. The ability to control temperatures with precision enhances the overall quality of the paper and reduces energy consumption.

Key Advantages Over Cast-Iron Dryer Cans: A Comparative Analysis

- Weight and Energy Efficiency: Steel Dryers are notably lighter than their cast-iron counterparts, leading to improved energy efficiency. The reduced weight contributes to lower energy consumption during operation, making Steel Dryers a greener and more cost-effective choice.

- Customization and Design Flexibility: JMC Paper Tech’s Steel Dryers provide unparalleled customization options, allowing for the adaptation of design to meet specific project requirements. This level of flexibility is a significant advantage over cast-iron dryer cans, which often come in standardized designs.

- Reduced Maintenance Costs: The durability and corrosion resistance of Steel Dryers result in decreased maintenance requirements and associated costs. Paper mills can benefit from extended operational periods between maintenance cycles, contributing to higher overall efficiency.

JMC Paper Tech Pvt Ltd has set a new standard in the realm of Steel Dryers through its commitment to customization, stringent quality controls, and a focus on mechanical properties that enhance efficiency and durability. As the paper industry continues to evolve, the versatility and advantages offered by Steel Dryers position them as a cornerstone in the pursuit of quality paper production.